Sawdust charcoal making machine offers a breakthrough for the wood processing industry. Rising waste volumes and pressure for green transformation create urgent challenges. This technology turns sawdust into clean, valuable charcoal. It reduces waste, cuts emissions, and supports renewable energy. Businesses gain efficiency and new revenue. Communities benefit from sustainable growth. With global adoption accelerating, more industries choose this reliable and profitable sawdust charcoal machine.

Sawdust Issues & Pyrolysis-Based Solutions in Wood Processing Industry

Industry Challenges

- High Storage Costs: large volumes of sawdust occupy valuable space.

- Low Transport Efficiency: loose, lightweight material is costly to move.

- Environmental Concerns: dust and open burning cause pollution and regulation pressure.

- Fire Hazards: sawdust is highly flammable, posing safety risks.

- Resource Waste: Discarded sawdust loses its potential utilization value.

Why Choose Pyrolysis?

Sawdust charcoal making machine can produce up to 6,000 tons of charcoal/biochar per year. achieving both waste reduction and resource utilization:

- Space-saving: converting sawdust into compact charcoal reduces storage demand.

- Cost-effective: on-site treatment avoids expensive disposal cost.

- Eco-friendly: lower emissions to meets environmental standards.

- Safe: pyrolysis educes the risks of fire and dust explosions.

- Profitable: get marketable charcoal products and carbon credits.

2 Models of Sawdust Charcoal Making Machines

Commercial Scale: BST-50

- 6,000 tons charcoal production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

- BST-50S technology vetted by puro.earth

Testing Scale: BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon sink process verification

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

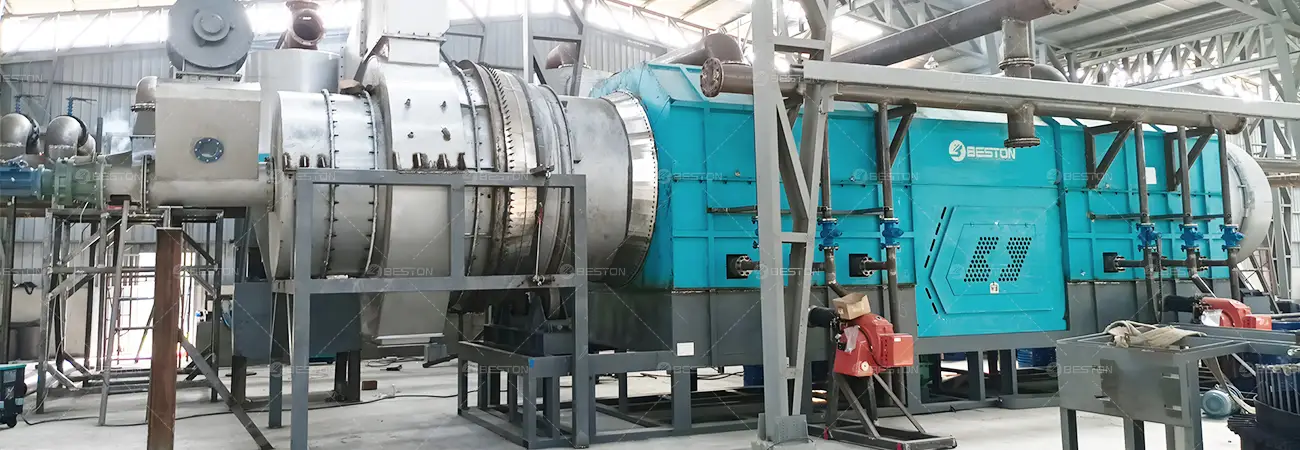

BST-50S Sawdust Charcoal Machine: Large Capacity & Reliable Output

Stable Recycling Efficiency

BST-50S sawdust charcoal machine features a self-cleaning system for tar/wood vinegar/dust. It enables continuous operation of up to 7,200 hours per year. This reliability brings multiple benefits for wood processing industry:

- Consistent Charcoal Production

Stable sawdust charcoal output, provides a reliable supply whether for on-site boilers or for sale to downstream customers. Generally, it ensures continuous flow of in-stock product. - Lower Operating Costs

Continuous operation reduces downtime enery cost, maintenance fees, and labor requirements. Thus, it maintains smooth production while lowering overall operational expenses.

Large Processing Scale

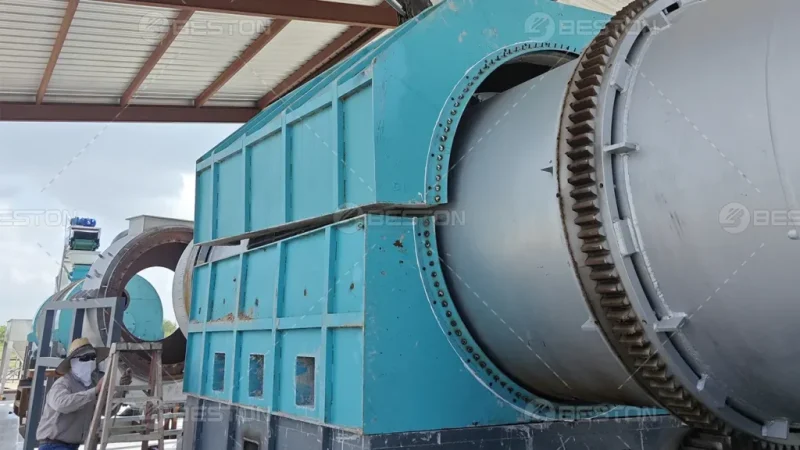

BST-50S wood to charcoal machine features a dual-tube main furnace design, ensuring a processing capacity of over 10 m³ per hour. This high throughput brings multiple operational benefits for the wood processing industry:

- Significant Space Savings

By converting loose sawdust (≈0.25 t/m³) into compact charcoal (≈0.7 t/m³), BST-50S can reduce peak storage space by nearly 90%, freeing up valuable factory area and improving site safety. - Reduced Disposal & Transport Costs

With high processing capacity, BST-50S can convert daily sawdust into charcoal on-site, minimizing the need for external hauling or landfill disposal. It lowers transportation and tipping expenses.

Profit Pathways of Sawdust Charcoal Production

Charcoal & Biochar Product Sales

Biochar Carbon Credits Trading

Soil Additive

- Application: Applied to farmland or degraded soils to improve fertility, retain water, and support microbial activity.

- Customer Base: Farms, agricultural cooperatives, and organic growers.

- Value Proposition: Enhances crop yields, reduces fertilizer input, and helps meet sustainable farming standards.

Construction Material

- Application: Mixed into cement, concrete, or asphalt to improve insulation, reduce weight, and lock carbon into long-term structures.

- Customer Base: Construction companies, eco-building material suppliers, and infrastructure projects.

- Value Proposition: Provides durable, low-carbon building materials and contributes to green certification in construction projects.

Feed Additive

- Application: Incorporated into livestock diets to improve digestion, reduce methane emissions, and support animal health.

- Customer Base: Cattle farms, poultry producers, and animal feed manufacturers.

- Value Proposition: Enhances feed efficiency, lowers veterinary costs, and improves sustainability performance in animal husbandry.

Industrial Fuel

- Application: Used in boilers, furnaces, and kilns as a clean, high-calorific replacement for coal or biomass briquettes.

- Customer Base: Manufacturing plants, food-processing facilities, and energy-intensive industries.

- Value Proposition: Provides a consistent, renewable fuel source with lower emissions and improved cost stability compared to fossil fuels.

Processing Feedstock

- Application: Serves as a raw material for producing BBQ charcoal, shisha charcoal, and activated carbon.

- Customer Base: Charcoal processors, activated carbon manufacturers, and specialty fuel producers.

- Value Proposition: Ensures reliable input quality and enables value-added product diversification for downstream industries.

Step 1: Carbon Removal Quantification

Carbon storage is calculated from biochar output, its fixed carbon content, and how stable the final use is. Standard methods allow each ton of biochar to be converted into measurable carbon removal, giving buyers clear and trusted data.

Step 2: Technology Check & Method Alignment

Projects must follow global rules. The BST-50S biochar machine passed Puro.earth’s review, proving that its production and tracking process meets international standards. This ensures credit quality and long-term storage, which is key for ESG and net-zero buyers.

Step 3: Certification & Credit Issuance

Independent auditors check projects before credits are issued. One Biochar Carbon Removal (BCR) credit equals one ton of CO₂ locked away. At USD 150–250 per ton, certification turns carbon removal into a strong income stream.

Step 4: Trading & Revenue Generation

BCR credits are sold to global companies, banks, and governments to offset emissions. Demand is high from firms with science-based targets, making BCRs a leading carbon removal option. Together with biochar product sales, credit trading boosts both project income and stability.

Successful Case: Sawdust Charcoal Making Machine in North America

01 Client Background

In August 2025, Beston Group delivered a BST-50 sawdust charcoal making machine to a bioenergy company in Brazil. The client, originally working with eucalyptus & bamboo sawdust from the local wood-processing sector, supplies clean fuels to the domestic market.

02 Problems Faced

The client previously relied on traditional earth kilns. This caused low output, unstable quality, and high labor demand. The kilns making it impossible to keep up with Brazil’s rising demand for barbecue charcoal. For large-scale sawdust processing, this meant wasted resources and limited ability to scale up.

03 Solution

We provided BST-50 biomass pyrolysis plant with a drying system to handle large volumes of eucalyptus & bamboo sawdust. The system provides a high degree of automation and stable operation. This allows Brazilian client to realize a high-value application of sawdust.

04 Value Added

- Stable Output: Delivers 6,000 tons of barbecue charcoal annually with consistent quality.

- Lower Costs: Automation reduces manual labor and operating expenses.

- Market Advantage: Strengthens competitiveness in the barbecue charcoal sector while supporting sustainable growth.

Working Processing

01 Sawdust Pretreatment

- Drying: Moisture is reduced to below 20% to improve pyrolysis efficiency.

- Screening: Proper size ensures smooth feeding and stable operation.

02 Sawdust Pyrolysis

- Moisture Removal: Rising temperature drives out water from sawdust.

- Gas Release: At 200–500℃, volatile gases are released. These gases serve as heating fuel for the reactor.

- Charcoal Formation: Above 500℃, sawdust turns into stable charcoal.

03 Combustible Gas Recycling

04 Flue Gas Utilization

- Direct Treatment: A part goes to the tail gas system after cyclone dust removal.

- Heat Exchange: A part enters the air-to-air exchanger to preheat combustion air.

- Drying Support: Another part heats the dryer to support sawdust drying.

05 Sawdust Charcoal Discharge

06 Tail Gas Treatment

Technical Advantages of Beston Biochar Prodcution Equipment

Tar/Wood Vinegar/Dust Self-Cleaning

- Tar & Wood Vinegar Cleaning: Sawdust charcoal making machine adds insulation measures in key parts and points. This ensures that tar and wood vinegar will not condense and clog.

- Dust Cleaning: The areas where carbon powder easily accumulates are equipped with a purge system, which effectively keeps the equipment pipes and components unobstructed.

High Thermal Efficiency

- Combustion System Upgrade: combustion system uses low-nitrogen burners. Combined with internal high-temperature oxygen distribution, it maximizes the utilization of thermal energy.

- Dual-cylinder Rotary Core Kiln: The carbonization furnace adopts a double-layer design. This can achieve deep dehydration and efficient pyrolysis.

Safety Guarantee

- Explosion-proof Design: Sawdust charcoal making machine adopts explosion-proof holes and explosion-proof water seals. They avoid safety accidents caused by overpressure.

- Dynamic Sealing: combination of various materials creates a multi-sealing design. It mproves the system’s airtightness, which prevents flammable gas leakage and improves safety.

Intelligent Operation

- PLC Control: precise temperature control system and variable frequency fan control ensure the stability of biochar production process. Thus, this ensures the consistency of charcoal quality.

- IoT Monitoring: operators can monitor data in real time. When parameters are abnormal, operators can respond in time to optimize the operating efficiency and safety of the equipment.

Beston Charcoal Production Solutions Across the World

Beston Group has successfully delivered over 150 charcoal production projects worldwide. From solution design to equipment manufacturing and on-site installation and commissioning, we provide complete one-stop services. These projects showcase how Beston Group helps customers in diverse industries achieve efficient, scalable, and sustainable charcoal production. The following are specific cases for your reference:

Driving Global Sustainability with Innovation

Sawdust charcoal making machine is more than equipment. It is a pathway for industries to achieve efficiency, sustainability, and long-term growth. From waste reduction to carbon removal, it helps businesses adapt to global climate goals and unlock new markets. Beston Group will continue delivering advanced solutions and reliable service worldwide. For more insights and success stories, follow us on our official LinkedIn page.