Tyre pyrolysis plant is an innovative tyre treatment solution. It is designed to recycle waste tyres into valuable products such as carbon black, pyrolysis oil and gas. In recent years, the number of waste tyres has been increasing worldwide. Pyrolysis technology provides an environmentally friendly way to reduce landfill waste while producing usable resources. Tire pyrolysis plant can effectively convert waste tyres into reusable materials, contributing to the sustainable closed loop of tyre recycling.

Tyre Pyrolysis Plant: Turning Waste into Valuable Resources

Tyres are primarily composed of rubber, carbon black, steel, and various chemicals. Tyre pyrolysis plant achieves the chemical recycling. The pyrolysis of tyre occurs under high-temperature, anoxic conditions. When exposed to heat, the rubber components in the waste tyres undergo thermal decomposition, transforming into solid, liquid, and gaseous by-products. The key stages of the pyrolysis process are as follows:

- Initial Stage: The long-chain polymer structures begin to break down, producing smaller hydrocarbon molecules.

- Mid-Term Stage: Continued pyrolysis leads to the generation of more light gaseous hydrocarbons and aromatic compounds.

- Final Stage: Stable carbon black forms, alongside some smaller gaseous molecules.

As the core technology, pyrolysis plant not only enables waste recycling but also provide a sustainable solution for resource utilization of tyres .

Pyrolysis Oil

Tyre pyrolysis oil is primarily composed of hydrocarbon compounds and boasts a high energy density. Its components include aromatic hydrocarbons, aliphatic hydrocarbons, and other olefinic substances.

Carbon Black

Carbon black constitutes about 30%-40% of a tyre’s weight. It is a fine black powder with high stability. Due to its non-volatility, carbon black remains as a solid product after pyrolysis.

Syngas

Inside tire pyrolysis plant, some organic matter decomposes into light gases, mainly including carbon monoxide (CO), carbon dioxide (CO₂), hydrogen (H₂), methane (CH₄), and various light hydrocarbon gases.

3 Operation Model of Tire pyrolysis Plant

Continuous Type: BLL-30

- Process 10,000 tons tyres annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

Batch Type: BLJ-20 Pyrolysis + Distillation

- Process 6,000 tons tyres annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 4,000 tons tyres annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 60 |

Cutting-edge Technological Breakthrough in Tyre Pyrolysis Plant

BLJ-20: Pyrolysis & Distillation Integration

BLL-30: 30 Days Continuous Operation

Fractional Distillation Technology

2 Types of Oil, 1 Step Collection

In condensation stage, naphtha with a boiling point below 200°C is sent to light oil tank. Non-standard diesel oil with a boiling point above 200°C is sent to heavy oil tank. Fractionation eliminates the need for distillation equipment while obtaining higher quality oil.

Large-Capacity Reactor

50%↑ Processing Capacity

BLJ-20 tyre pyrolysis reactor, with dimensions of ø2800*10000. It offers a 50% increase in processing capacity compared to traditional waste tyre pyrolysis plant. Processing capacity increased from 10-12 tons per batch to 18-20 tons per batch.

Sealing & Insulation Upgrade

No Open Flame, No Oil Gas Leaks

BLJ-20 uses thermal dynamic sealing and flexible high-temperature insulation technology. There are no oil gas leaks or open flames at the operating site. This technology significantly improves operational safety and reduces the risk of thermal hazards.

Anti-polymerization Condensation

30 Days Continuous Operation

BLL-30 continuous tyre pyrolysis plant adopts oil-gas spray mixing condensation, the technology quickly lowers temperature and improves condensation efficiency. It prevents olefin compounds from secondary polymerization and clogging the pipes.

Hot Flue Gas Recirculation

↓ 55% Fuel Use & ↓ 50% Emission

High-temperature flue gas from pyrolysis flows in two directions. 80% is evenly mixed with hot air in combustion chamber to heat pyrolysis reactor. Meanwhile, 20% heats the burner combustion air. This improves thermal efficiency and alleviates emission impacts.

Automatic Temperature Control

80% Less Manual Work

Multi-medium automatic combustion valve group combined with hot air heating realizes precise temperature control of ±10℃. With continuous feed / discharge, tire pyrolysis machine only requires two operators, which reduces manual intervention by 80%.

High-value Utilization of rCB Achieves Fivefold Revenue Increase

Not only fuel oil, tire pyrolysis plant transforms waste tyres into valuable carbon black (rCB). By enhancing the quality of rCB through precise temperature control and advanced processing, the equipment not only support sustainable waste management but also enable significant revenue growth by producing high-value carbon black suitable for various industrial applications.

High-quality Pyrolytic Carbon black Output

Precise temperature control is key to ensure high-quality pyrolytic carbon black out put. This technology can optimize the properties of carbon black to meet the following stringent rCB requirements:

- TPH meets standard: By avoiding excessive cracking of hydrocarbons at high temperatures, tyre pyrolysis plant reduces Total Petroleum Hydrocarbons (TPH) formation. This improves the purity and stability of rCB.

- Toluene permeability meets standard: Precise temperature control ensures that the pore structure of carbon black is more stable. This effectively enhances the durability and chemical stability of carbon black.

High-value N550/N660 Preparation

The combined grinding and granulation process makes carbon black a high-value product with higher specific surface area and improved particle size distribution. It is reflected in the following two aspects:

- Increase specific surface area of carbon black: The specific surface area of rCB is significantly improved through grinding and granulation. This not only increases the reactivity, but also better adapts to various formulation requirements.

- Preparation of N550/N660: This process enables rCB to be used to prepare higher standard N550 and N660 carbon black specifications. It is suitable for the production of high-performance tires, rubber products and coatings.

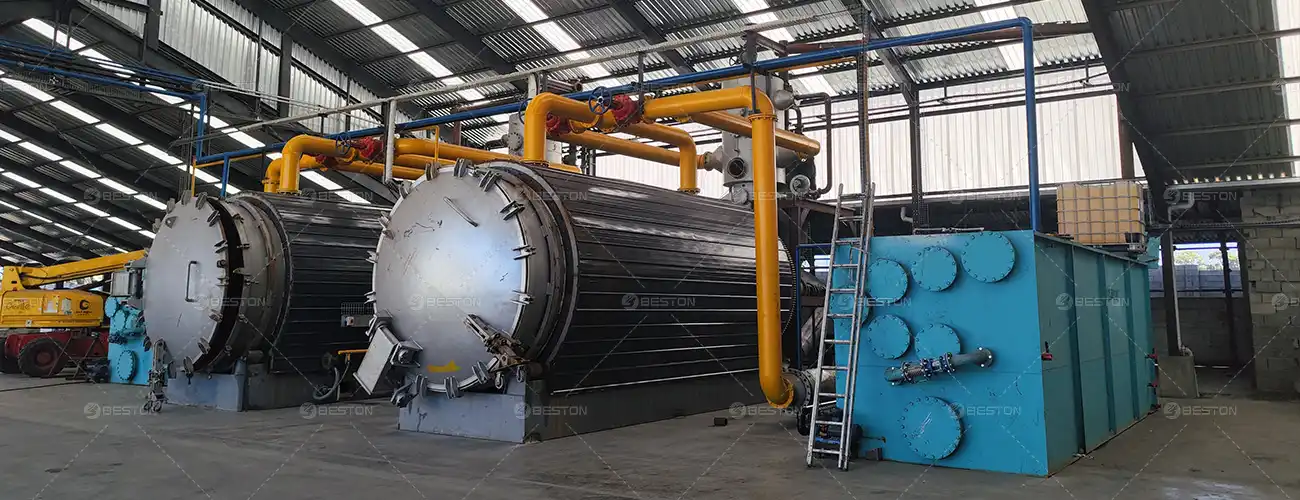

Successful Showcase of Tire Pyrolysis Plant in South Africa

01 Problems & Challenges

The South African customer faces two main challenges: a large amount of non-recyclable plastic and tyre waste, and high fuel costs at the smelting plant. They need an efficient solution to reduce waste and lower energy expenses.

02 Change in Goals

The customer aims to address both waste accumulation and high energy costs by implementing an eco-friendly solution. They identified pyrolysis as the most suitable technology to reduce waste volume, and replace traditional energy sources, thereby lowering operational costs.

03 Action Solution

Beston Group provides the customer with two BLJ-16 tyre/plastic pyrolysis plants adopts catalytic towers and a BZJ-10 distillation unit. This configuration enables large processing capacity (8-10 tons of plastic and 10-12 tons of tyres per batch), reduces wax oil clogging, and improves fuel quality. The pyrolysis oil serves as a replacement for expensive energy sources at the smelting plant.

04 Results Achieved

BLJ-16 plastic/tyre pyrolysis plant successfully reduced 7,000 tons of plastic and tyre waste annually, converting it into valuable energy resources. Fuel costs at the smelting plant are significantly reduced by using pyrolysis oil for aluminum furnaces and truck fuel. The process also contributes to lower carbon emissions and reduced fossil fuel consumption. Thus, it enhances the customer’s environmental reputation.

Transformative Solutions Enabled by Tyre Pyrolysis Plant

Diversified Profitability

Tyre pyrolysis equipment transforms waste tyres into a variety of valuable products. Diversified market demand provides substantial profit sources:

- Pyrolysis Oil: As a high-energy-density liquid fuel, it is widely used in industrial equipment, boilers, etc. It can meet the energy needs of various heavy industrial sectors.

- Non-standard Diesel: As a high-quality heavy oil fuel, it is suitable for transportation, power generation, heavy equipment, etc. It helps reduce production and transportation costs.

- Naphtha: As a light oil product from the pyrolysis process, naphtha is an important raw material for the production of recycled plastics, chemicals, and clean fuels.

- Carbon Black: In rubber product manufacturing, carbon black is an important additive. It is also widely used in coatings, batteries, and synthetic materials industries.

Environmental Impact Mitigation

Improper disposal of tire waste can cause serious environmental problems. Tyre pyrolysis plant offers an effective solution that can significantly mitigate these negative impacts:

- Reduced Ecological Pollution: Tyre pyrolysis prevents the release of harmful substances during tire decomposition in landfills. Furthermore, through an efficient waste stream processing system, the plant reduces the emission of harmful substances. This ensures that pollution to water sources, soil, and air is minimized.

- Eliminating Fire Hazards: Waste tyres are prone to spontaneous combustion when stored in the open, posing a fire risk. Pyrolysis ensures the safe disposal of waste tires. This not only reduces the fire risk from open storage but also avoids various environmental and safety hazards caused by fire.

Circular Economy Promotion

Tire pyrolysis plant not only effectively solves the problem of waste tire disposal but also plays a crucial role in promoting resource recycling and driving the development of a circular economy:

- Recycled Tyre Production: rCB produced during pyrolysis is a valuable industrial raw material. It can replace natural carbon black in recycled tire production. By improving the recycling rate of waste tire resources, this promotes sustainable closed-loop production in the tire industry.

- Fossil Fuel Substitution: Tyre pyrolysis oil serves as a green alternative energy source. It replaces traditional fossil fuels and effectively reduces dependence on non-renewable resources such as petroleum. This has a positive impact on achieving global climate change mitigation goals.

Operation Process of Waste Tyre Pyrolysis Plant

01 Tyre Feeding

02 Tyre Pyrolysis

03 Oil Gas Condensation

04 Gas Treatment

- Syngas Recovery: The non-condensable components in the high-temperature oil gas are purified to form syngas. The syngas is used to provide energy for the tyre pyrolysis machine.

- Exhaust Gas Discharge: The remaining exhaust gas is cooled and dust is removed through a condenser and spray tower, and then discharged through the chimney.

05 Carbon Black Discharge

Technical Advantages of Tire Pyrolysis Plant

Inert Gas System

When the tire pyrolysis machine is started and stopped, the system introduces inert gas (nitrogen) for gas replacement. Through nitrogen replacement, the residual combustible gas and air in the reaction furnace can be effectively removed. Thus, this prevents the flash explosion of the main furnace and ensures the safe operation of the equipment.

Hot Air Heating

Compared with burner heating, the hot air heating system provides more uniform heating and more precise temperature control. Most importantly, the hot air heating system can achieve waste heat recovery, saving 20-30% of energy consumption. Thus, this significantly improves energy efficiency and environmental benefits.

Floating Seal Technology

The floating seal technology uses a sealing method that combines carbon fiber and high-temperature soft filler. Compared with traditional graphite filler sealing technology, Beston‘s seal has stronger resistance to high-temperature corrosion and wear. Therefore, it can stably and long-term guarantee the sealing effect of the waste tyre pyrolysis plant.

Reliable Insulation Material

High-temperature ceramic wool is used for the internal insulation material of the equipment’s casing. You can choose to use Morgan brand high-temperature ceramic wool. This material does not pose a risk of cancer or lung infection to workers, and meets EU standards to ensure worker safety and environmental protection requirements.

Why Choose Beston Group as Your Tyre Pyrolysis Plant Manufacturer?

Strong R&D Capabilities

- Experienced Team: Beston’s R&D team consists of over 50 skilled engineers. The majority have over 10 years of industry experience. Their expertise spans mechanical design, materials science, and automation control.

- Advanced Facilities: Our R&D center features modern laboratories and pilot plants. These facilities support both routine testing and the development of innovative technologies.

End-to-End Quality Control

- Premium Materials & Components: We use high-quality steel materials meets international standards. All components are from top-tier brands, ensuring durability of tyre pyrolysis plant.

- Comprehensive Inspections: Multiple quality checks are performed throughout the production process. These include airtightness tests, reactor assessments, and ultrasonic testing to ensure the safety and functionality of the equipment.

Integrated Service Support

- Pre-sales Assistance: We provide tailored product configurations. Customers are welcome to visit our production site.

- In-sales Updates: We keep customers informed about progress. We also assist with preparation for civil engineering work.

- After-sales Care: Our engineers guide installation and commissioning. We also offer professional training support.

EPC Engineering Support

- Complete Construction Services: Beston handles the entire construction process, including factory buildings, office structures, and infrastructure. This starts with a valid land survey report.

- Efficient Project Delivery: Our EPC service accelerates the commissioning of tire pyrolysis equipment. It also cuts down on costs compared to developing self-built facilities.

Global Success Cases: Tyre Recycling Solutions Trusted Worldwide

Beston Group’s tyre recycling solutions have been successfully deployed around the world. Our tyre recycling pyrolysis plant is highly recognized for their efficiency and reliability. As a result, numerous customers from different countries choose Beston as their long-term partner. Thus, customers benefit from our advanced technology and sustainable practices in tyre pyrolysis. Below, explore the cases behind these successful collaborations. Find out how Beston Group is shaping the future of recycling, including plastic, oil sludge, waste tyre, etc.

Join Tyre Recycling Ranks with Beston Group’s Solution

In summary, tyre pyrolysis plant provides an efficient and eco-friendly method of recycling waste tires. It plays a key role in the circular economy by transforming tires into valuable materials and reducing waste. By investing in waste tyre pyrolysis plant, investors not only contribute to sustainable development. Also investors can unlock new business opportunities, ensuring long-term profitability and environmental responsibility. To get the latest news on tire recycling, follow us on LinkedIn.