Pyrolysis plant in Australia is a project that can turn some waste into useful products. In Australia, some investors are looking for projects that can convert some non-degradable waste into valuables. Pyrolysis equipment is such a project. The final pyrolysis oil and carbon black can bring good returns to investors.

Raw Materials of Pyrolysis in Australia

Australia is rich in pyrolysis raw materials such as tyres, plastics and rubber. Besides, oil sludge can also be processed by Beston pyrolysis equipment. These wastes are all non-degradable garbage, which pollutes the environment very seriously. Australia’s land and seas are now polluted. If Beston pyrolysis equipment is used to process these wastes, the final product can help both Australia’s economy and the environment.

| Raw Materials | Final Products |

| Tyre | Pyrolysis Oil, Carbon Black, Steel Wire, Syn-gas |

| Plastic | Pyrolysis Oil, Carbon Black, Syn-gas |

| Rubber | Pyrolysis Oil, Carbon Black, Syn-gas |

| Oil Sludge | Pyrolysis Oil, Sand, Water |

The Current State of Non-degradable Waste Recycling in Australia

In Australia, recycling rates are not high. And after some countries banned the import of tires and plastics, Australia’s waste recycling rate has also been affected. Now, more waste plastics are further processed into plastic products or used as fuel in Australia. The approach to recycling tires is landfill. So, investors are in desperate need of a project that can turn these wastes into useful finished products now. And this project will not pollute the environment.

Why Use Beston Pyrolysis Plant to Recycle Waste in Australia

Beston tires pyrolysis equipment can convert this waste into valuable pyrolysis oil. And the whole process is pollution-free. Compared with other recycling methods, pyrolysis can recover these raw materials more fully. Iron wire and combustible gas can also be recycled. And, the end product is abundant. Beston pyrolysis equipment strictly controls the quality. And we provide excellent after-sales service. Welcome to ask us.

Beston Pyrolysis Plant for Sale in Australia

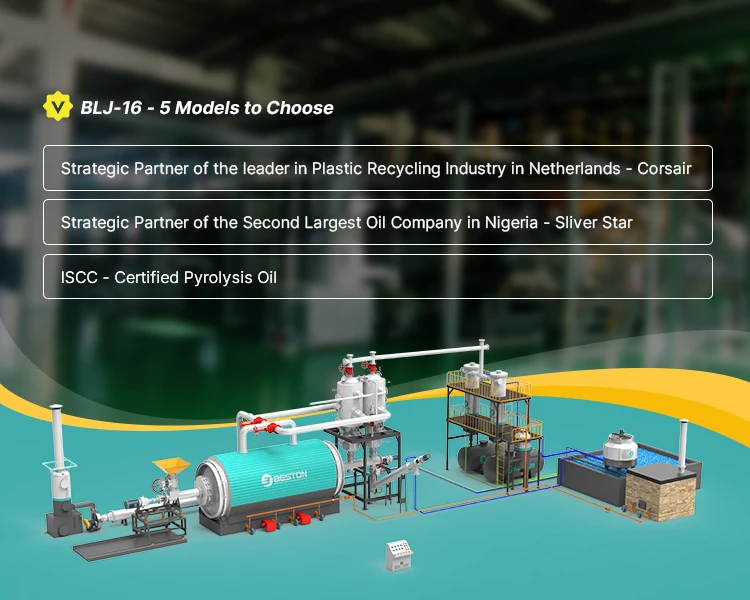

Beston pyrolysis equipment is divided into five models, including BLJ-3, BLJ-6, BLJ-10, BLJ-16, and BLL-30. These models have different features. And they are suitable for different customer groups. In addition, these machines are equipped with de-dusting systems to purify the final flue gas.

Parameter of Beston Pyrolysis Plant for Sale in Australia

The following five models have different capacities, working methods and other parameters. See the following table in detail.

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Materil | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

Video of Beston Pyrolysis Plant

The video below is of Beston pyrolysis project site in Anhui, China. This video mainly shows the raw materials and the project site. And the final pyrolysis oil nearly has no residue. And the quality of pyrolysis oil is good. Carbon black is collected in carbon black bags. The particle size of carbon black is extremely small. This customer is very satisfied. Watch the video if you want to learn more.

Beston Pyrolysis Machine Shipped to Australia

Beston sent a set of BLJ-3 pyrolysis equipment to Australia in January 2022. This equipment is used to process imported waste tires and used tires from tire factories. The final pyrolysis oil is used as fuel for the plant to burn.

This customer found us through Google. This customer had no previous exposure to this field. Also, it was difficult to get an EIA certificate in Australia. But we said that if this customer has any need, we can help him. And we offered a range of services. This made this customer feel that Beston was very professional. And he chose to work with us. If there is a need later, he will contact us again.

Pyrolysis Process in Australia

Put the right size raw material into the feeder. If the feeder has size requirements, the raw material can be cut into small pieces using a crusher.

Preheat main furnace. After the pyrolysis begins, oil and gas, oil, and carbon black are continuously produced. The gas enters the pipeline and is processed by a series of equipment before being reused in the burner. Heavy oil is drained from the pipeline into the tank. Carbon black is discharged into the carbon black tank.

The flue gas produced during the pyrolysis process will undergo a series of treatments to meet EU emission standards. If your country has strict emission standards, we offer other decontamination procedures to meet your requirements.

Note: see the detailed waste prolysis process.

Beston pyrolysis plant for sale in Australia is a good line to process waste. When customers use this pyrolysis line, the final products bring good economic benefits to customers. Moreover, the pyrolysis process in Australia is environmental-friendly. This line won’t pollute the environment. If you are interested in Beston waste pyrolysis plants, contact us right now. You can follow us on Beston Facebook.