Plastic to oil machine is a groundbreaking technology that transforms non-recyclable plastics into valuable pyrolysis oil and other by-products. This innovative process helps address the growing plastic waste crisis while producing sustainable energy alternatives. By converting waste plastics into usable fuel, the machine not only reduces environmental pollution but also provides a cost-effective solution for industries in need of alternative energy sources. Plastic to oil plant plays a key role in advancing circular economy goals.

2 Types of Beston Plastic to Oil Machine for Sale

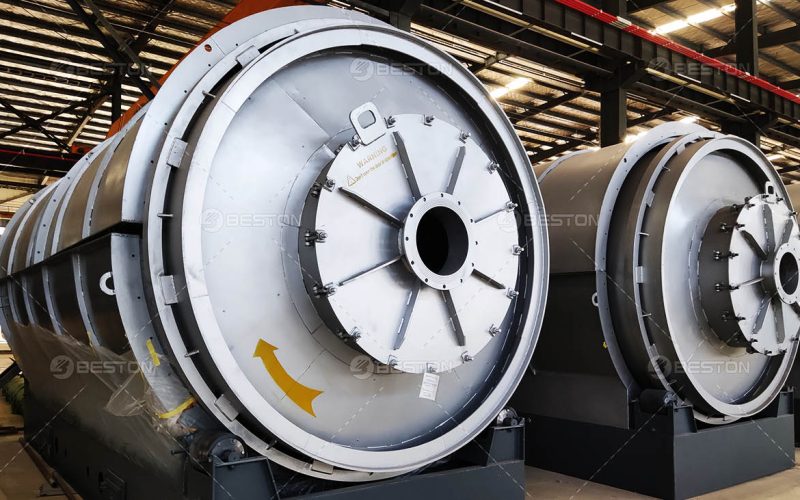

Continuous Type: BLL-30

- Process 6,000 tons waste plastic annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

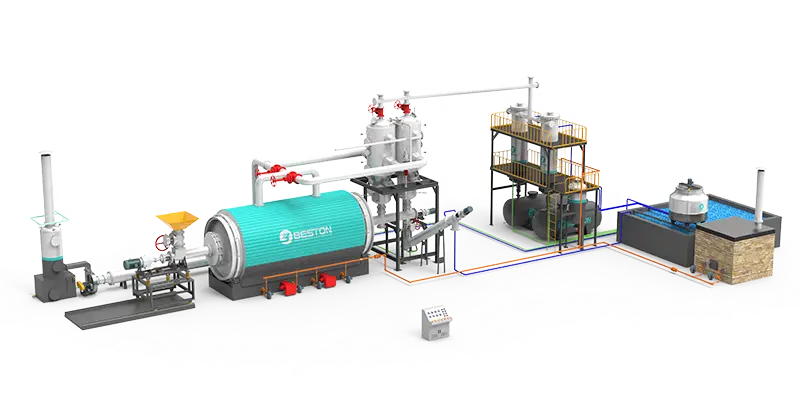

Batch Type: BLJ-20

- Process 4,000 tons waste plastic annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons waste plastic annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

Successful Case: Plastic to Oil Project in Finland

01 Client Background

Developing country’s “foreign waste” import ban has reshaped global waste flows, leaving Europe and North America unable to export plastic waste as before. Finland, with its strong environmental awareness, faces the same challenge. To tackle this, Corsair Group has decided to build a pilot plant with Beston Group’s plastic to oil machine, aiming to demonstrate a sustainable and circular pathway for plastic waste.

02 Problems Faced

- Plastic waste can no longer be exported overseas, forcing local treatment solutions.

- Large volumes of plastic waste create environmental and social pressure.

- It is necessary to prove economic feasibility while meeting strict emission standards.

03 Solution

- Provide 10 sets of BLJ-16 plastic to fuel machines, each with a daily capacity of 8–10 tons, designed for different plastic waste streams.

- Equip units with a dual system (manifold + catalytic system) to improve stability and efficiency.

- Adopt a joint operation partnership, including personnel training and shared management, to ensure long-term success and maximize ROI.

04 Value Added

- Three plants are under installation, while seven are in planning, with an annual capacity of 30,000 tons of waste plastic processing.

- Expected to cut about 60,000 tons of carbon emissions per year, providing a replicable model for other European countries.

- Pyrolysis oil will be sold to partners as a feedstock for new plastics, making the machine a key driver in Europe’s transition to circular economy.

Catalytic Innovation for Plastic to Oil: 200% Efficiency Boost

Production Efficiency Assurance

In a plastic to oil plant, wax oil residues often cause blockages and downtime. The catalytic liquefaction technology breaks down these heavy components, ensuring smooth operation without clogging or equipment failure. As a result, the plastic pyrolysis machine can run continuously and improve production efficiency by up to 200%.

Oil Quality Assurance

During plastic to oil process, catalytic system converts heavy wax oil into lighter hydrocarbons. This transformation not only enhances the stability of the fuel but also improves its combustion performance. With fewer impurities and better consistency, the oil from the machine is suitable for a wider range of applications.

What Types of Plastic Can Plastic to Oil Machine Process?

Plastic oil plant provides comprehensive solutions for processing different types of plastics. Below, we’ll take a closer look at the compatibility of plastic to oil pyrolysis equipment with various plastic types. Thus, learn about their oil yield, origin, and unique properties.

PET

- Oil Yield: 0%;

- Sources: transparent bottles, mechanical parts, fiber products, etc.

- Feature: The oxygen produced by the reaction poses a safety hazard.

HDPE

- Oil Yield: 85%~95%;

- Sources:daily necessities containers, pipe fittings, household items,etc.

- Feature: high tensile strength, corrosion resistance.

PVC

- Oil Yield: unstable;

- Sources: wire insulation, municipal pipes, outdoor building materials, etc.

- Feature: oil obtained from PVC contains chlorine. Burning oil produces dioxins.

LDPE

- Oil Yield: 85%~95%;

- Sources:packaging films, bags, disposable tableware, etc.

- Feature: low strength, good flexibility, easy collection

PP

- Oil Yield: 80%~90%;

- Sources:food packaging, medical supplies, household products, etc.

- Features: good heat resistance, chemical corrosion resistance.

PS

- Oil Yield: 80%~90%;

- Sources: disposable tableware, lightweight casings, crafts, etc.

- Features: Good formability, meets food grade certification standards.

ABS

- Oil Yield: 40%;

- Sources: Electrical appliance shell, daily necessities, advanced toys, etc.

- Features: good mechanical properties, easy to paint and print.

Plastic to Oil Process: Reshaping of Polymers

In a waste plastic to oil machine, waste plastics do not change into oil instantly. The transformation happens step by step at the molecular level. By looking at how polymer chains break down and reshape, we can understand how solid plastics gradually become liquid fuel oil:

Primary Chain Scission

At high temperatures, carbon–carbon or carbon–hydrogen bonds in the polymer chain break. The long chains split, and unstable free radicals form.

Progressive Cracking

Radicals move along the chain and attack nearby bonds. Through β-scission, long chains transform into shorter fragments, C₅–C₂₀ range hydrocarbons form.

Molecular Stabilization

Free radicals couple, or they take a hydrogen atom from another molecule. As a result, chain ends close and stable small molecules form pyrolysis oil.

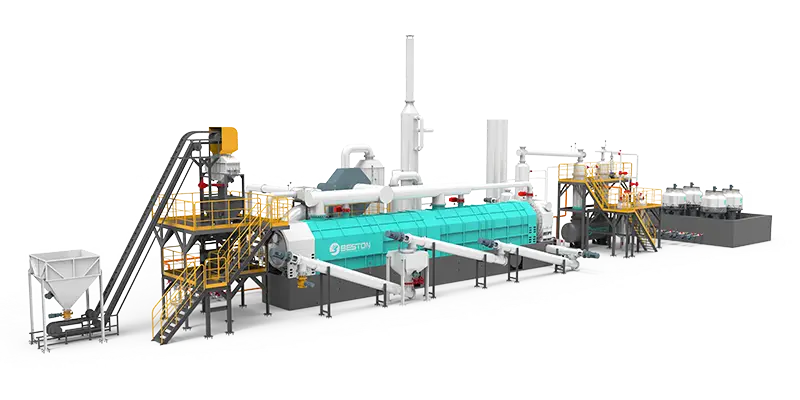

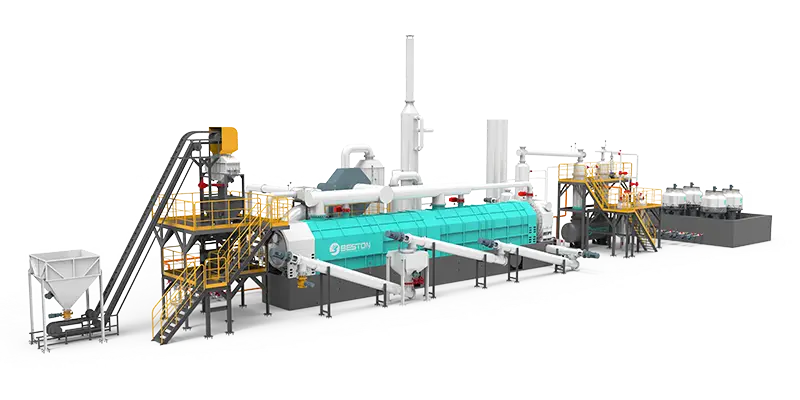

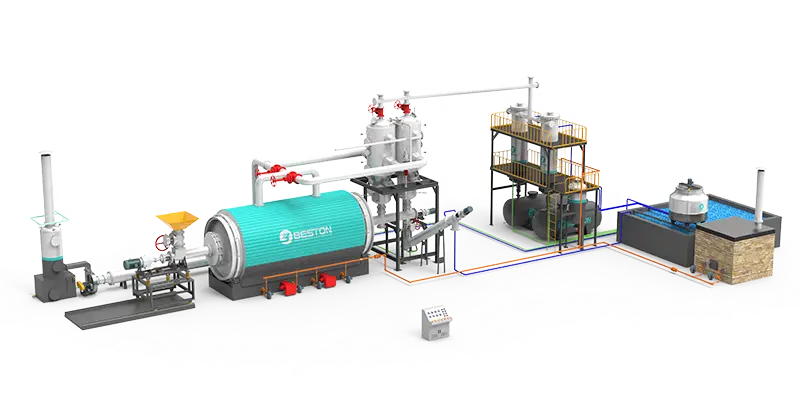

Workflow Display of Plastic to Oil Machine

The waste plastic to oil machine is an innovative solution for managing plastic waste and generating usable fuel. It can help reduce the amount of plastic waste that ends up in landfills or oceans while providing a sustainable source of fuel. The process typically involves several stages, including pretreatment, feeding, plastic to oil conversion, discharging, de-dusting, and syngas recycling.

01 Pretreatment

The pretreatment process involves sorting and cleaning the plastic waste. It’s essential to remove any contaminants, which can negatively impact the conversion process. The cleaned and sorted plastic waste is then shredded into small pieces for easier handling and processing.

02 Feeding

Customers have three feeding methods to choose from: manual feeding, hydraulic feeding, and screw feeding. Each model of the plastic to oil machine corresponds to different feed sizes. Please refer to the table below for details:

| Model | BLJ-16 | BLL-30 |

|---|---|---|

| Manual Feeding | bale<1200mm | / |

| Hydraulic Feeding | bale<1200mm | / |

| Spiral Feed | bale<50mm | bale<20mm |

03 Pyrolysis

- After feeding, the plastic enters the pyrolysis furnace of the machine. The reaction begins under high temperature and micro-oxygen conditions.

- Reaction Principle: During the reaction, long hydrocarbon chains in the plastic break down into smaller, lighter hydrocarbons known as oil gas.

- Reaction Process: Preheat the reaction furnace for 3-4 hours. Oil gas is produced at 180℃. The reaction becomes stable and oil gas is generated in large quantities between 280–350℃.

04 Oil Formation

- High-temperature oil and gas enter the catalytic tower, unique to the plastic to oil process, reducing wax oil formation.

- The oil and gas then enter the manifold, where impurity oil is separated and sent to the residual oil tank.

- The remaining oil and gas enter the condensation system. Heat exchange in the oil channel condenser converts them into liquid oil, which flows into the storage tank under gravity.

05 Syngas Reuse

- Under reaction pressure, non-condensable syngas enters the water seal. Purified syngas is reused to provide energy for the plastic to oil plant.

- Syngas usually consists of hydrogen, methane, and carbon monoxide. It can also be collected for other industrial uses.

06 Solid Discharging

- Remaining solids, such as carbon black, are removed from the reactor chamber of the machine.

- These solids can be used for road construction or mixed with other materials for industrial purposes.

07 Exhaust Gas Treatment

Waste gas is first cooled in the flue condenser, then further cooled and dust-removed in the spray tower. For high emission standard areas, high-end exhaust gas treatment systems provide desulfurization and denitrification. The treated gas meets EU standards before discharge from the chimney.

How Plastic to Oil Machine Delivers Sustainable Solutions?

Sustainable Plastic Recycling

Currently, about 350 million tons of plastic waste are generated every year. Less than 10% of this waste is recycled back into products. The rest ends up in landfills, incinerators, or the environment. Introducing plastic-to-oil machines can convert contaminated or low-value waste plastics into usable pyrolysis oil and by-products. This process significantly increases recycling rates and reduces environmental emissions.

Alternative Fuel Production

We need to reduce reliance on fossil fuels in the long term. Yet, in the short to medium term, energy demand, transport fuels, and industrial raw materials still face a gap. Geopolitical tensions and emission targets also make traditional supply less stable. Plastic to oil plant can produce alternative fuels or chemical feedstocks. This helps fill fuel gap and provides a reliable energy for industrial and transport sectors.

Diversified Revenue Streams

The plastic pyrolysis market was valued at several hundred million USD in 2023 and is expected to grow several times by 2030. Segments like pyrolysis oil also show steady growth. Using plastic to oil machine not only processes waste plastics but also produces saleable pyrolysis oil and by-products. At the same time, it opens multiple revenue channels, including processing fees and carbon credits, improving project profitability.

Cutting-edge Technology of Plastic to Oil Plant

Cutting-edge technology has always been the main reason why investors choose Beston Group‘s plastic to oil machine. What’s more, our technical team has always been committed to the R&D of more advanced technologies. Here are some of the great technologies that make our machines stand out.

High-end Exhaust Gas Treatment

The high-end exhaust gas treatment system mainly consists of an activated carbon dust collector, electrostatic precipitator, denitrification tower, desulfurization tower, and chemical feeding tank. This system removes dust particles and nitrogen sulfide from exhaust gas through multi-channel equipment. The final exhaust gas can meet the following emission standards: SO₂<50 mg/m³, NOₓ<200 mg/m³, PM<10 mg/m³, HCl<10 mg/m³, HF<1 mg/m³.

Diverse Wax Oil Removal Solution

Wax oil can clog the pipe from the plastic to the oil machine. Beston Group offers two solutions to deal with this problem.

- Install the catalytic tower. This configuration uses a catalyst to reduce the condensation and liquefaction of waxes in plastics.

- Install the electrode boiler. Based on the vertical condensation configuration, this solution can achieve the collection of wax oil.

Reliable Sealing Technology

Beston Group provides innovative sealing technology. The technology consists of a combined seal of high-carbon fiber packing rings and high-temperature flexible soft fillers. This technology can greatly improve the high-temperature sealing and operation convenience. The technology is currently used on BLL-30 and machines equipped with catalytic configurations.

IoT Monitoring System

The Internet of Things system (optional) ensures real-time feedback on operating status and timely diagnosis of faults. Customers can set corresponding early warning values for each parameter based on the properties of the monitoring data. When the monitoring data triggers an early warning, customers can view the equipment’s operating data and fault information in real-time.

Cooperate with Beston to Get Plastic to Oil Recycling Solution

Plastic to oil machine plays a key role in our mission to solve the global plastic waste problem. With its efficiency and eco-friendly technology, it helps convert plastic waste into valuable resources, contributing to a more sustainable future. We are committed to advancing plastic waste management solutions and promoting a circular economy. If you share our vision, we invite you to connect with us on LinkedIn to stay updated on our latest initiatives and progress.