Pyrolysis plant cost is a critical consideration for investors planning waste recycling projects. What makes cost so important is that it directly impacts the overall return on investment. Several factors contribute to the cost, such as the scale of the machinery, technology used, and supporting services provided. Understanding these elements helps investors make informed decisions when choosing the right equipment and solutions for their projects. Furthermore, by carefully evaluating these factors, investors can minimize operating expenses and maximize the profitability of their projects.

Pyrolysis Plant Cost When Setting Up Project

Pyrolysis Equipment Procurement

Optional Equipment Configuration

Shipment & Installation Fee

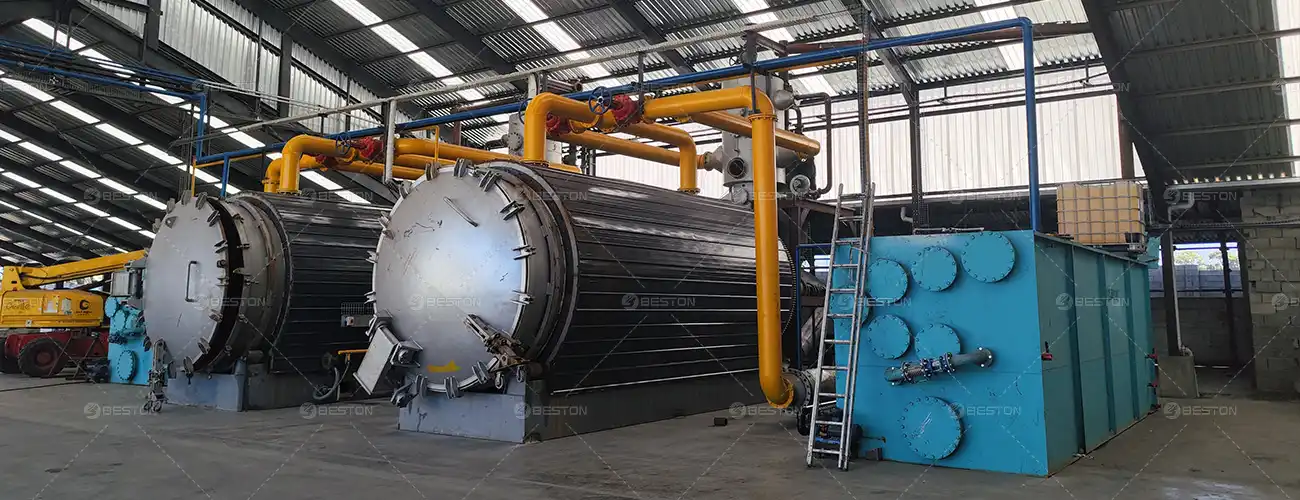

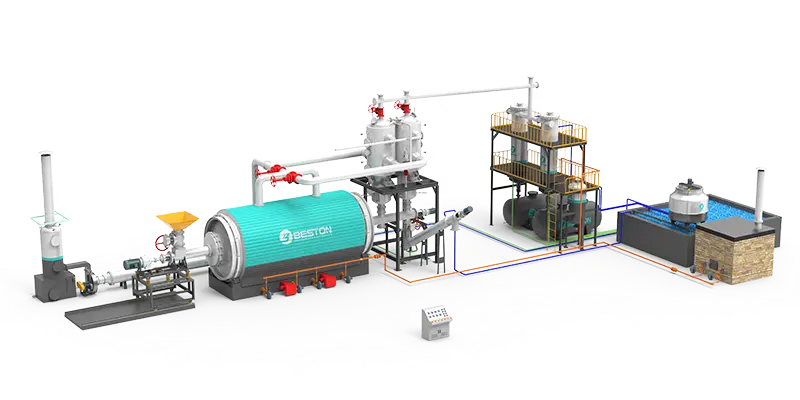

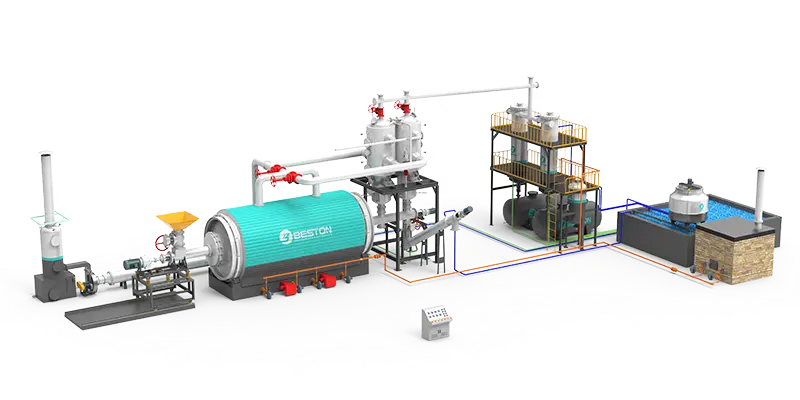

Beston Group provides 2 types of equipment, including batch type (BLJ-16/BLJ-20) and fully continuous pyrolysis plant (BLL-30). They have different processing volumes and automation levels. In general, higher processing capacity and degree of automation determine higher pyrolysis machine costs. Just pick up an appropriate line according to your production needs.

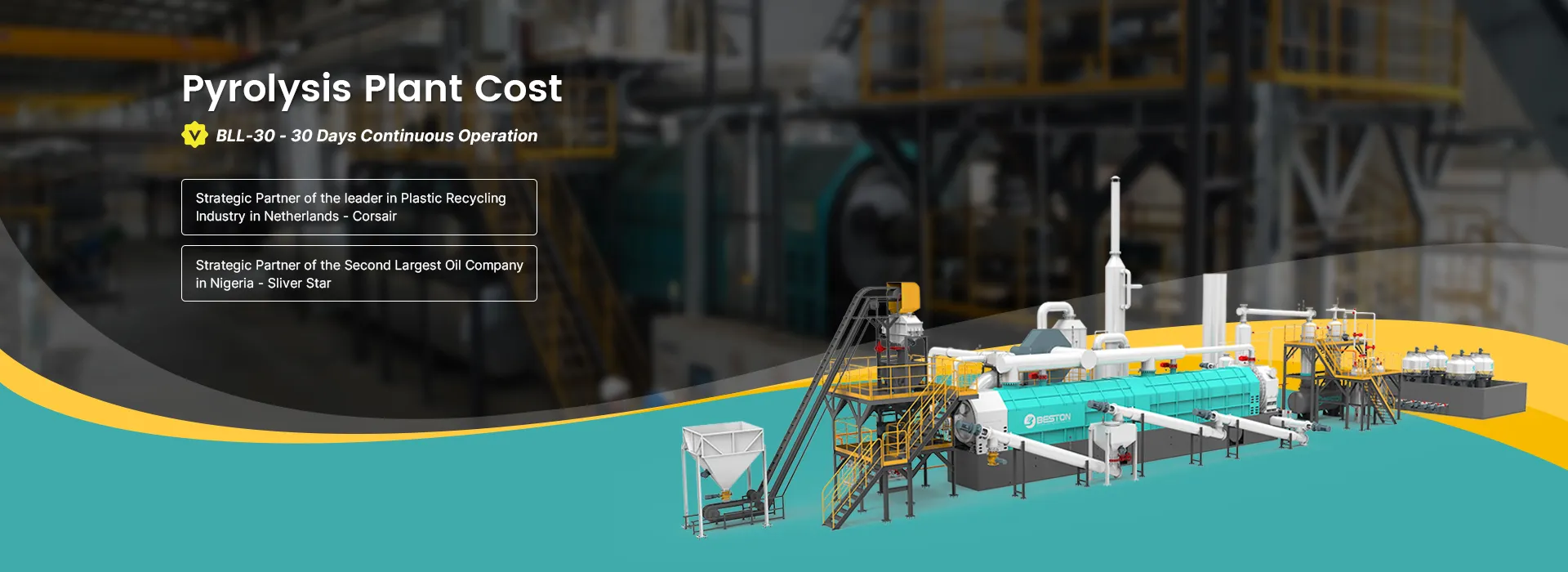

Continuous Type: BLL-30

- Large-scale processing choice

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

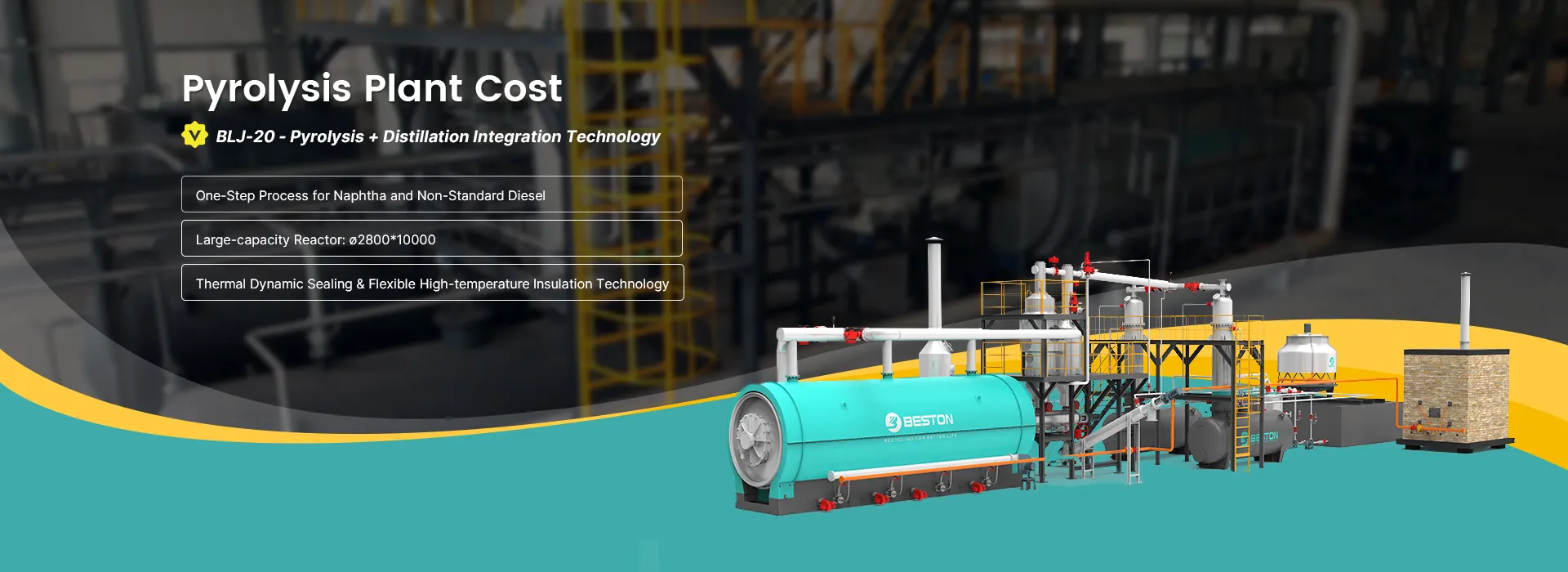

Batch Type: BLJ-20

- Large-capacity Pyrolysis Reactor (ø2800*10000)

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Small processing choice

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Materil | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

In addition to the core pyrolysis plant, several optional equipment configurations can be included as part of the total pyrolysis machine price. These additional units enable the pyrolysis projects to meet higher operational and environmental standards.

Tyre Shredder

To achieve a more efficient feeding process, waste tires are often required to be shredded into smaller, uniform pieces. Tyre shredder helps improve feed uniformity, ensure stable reactor operation, and enhance overall system performance.

High-End Exhaust Treatment System

For projects operating under stricter environmental regulations, an advanced exhaust treatment system is recommended. This equipment enables multi-stage gas purification to meet EU emission standards, ensuring clean and compliant exhaust discharge.

Distillation Equipment

To produce higher-grade oil products, a distillation system can be added to further refine pyrolysis oil into non-standard diesel and naphtha. This process expands the range of applications and significantly increases the commercial value of the end products.

Transportation Cost

This includes shipping costs from the manufacturer’s location to the destination country. Furthermore, there are land transportation costs from the port to the project site. Some locations are far away or have complex transportation conditions. Therefore, investors must also consider additional expenses such as transshipment and lifting.

Civil Construction Cost

This pyrolysis plant cost covers the basic construction required for factory construction, such as foundation pouring, structural support, equipment platforms, drainage and pipeline laying, and electrical system access. High-standard civil construction not only affects the accuracy of equipment installation but also has a direct impact on the long-term operation.

Site Licensing and Permit Fees

During the initial stages of project construction, multiple permits must be applied for, including land use permits, construction permits, and environmental impact assessments (EIAs). These costs, including government approvals, technical documentation, and third-party assessments, are essential for ensuring project compliance.

Labor Cost for Engineers & Workers

This includes labor costs during equipment installation, commissioning, and trial operation. Beston Group dispatched experienced engineers to provide technical guidance and worked with local workers to complete installation and training. This laid the foundation for the client team’s independent operational capabilities.

Operational Cost of Pyrolysis Plant

Raw Material Cost

- Cost Composition: Includes the procurement costs of raw materials such as waste plastics, oil sludge, and waste tires. It also includes transportation, storage, and processing costs related to raw materials.

- Influencing Factors: Market price fluctuations of raw materials, transportation distance, and supply chain stability.

- Optimization Plan: Establish long-term partnerships with suppliers. Optimize inventory management and transportation routes.

Energy Cost

- Cost Composition: Includes electricity consumption for factory operations. It also includes the pyrolysis plant cost of energy required for heating the pyrolysis reactor, such as natural gas, diesel, and LPG.

- Influencing Factors: Energy price fluctuations, equipment energy efficiency, and production scale.

- Optimization Plan: Use alternative energy sources (e.g., syngas produced by pyrolysis). Improve equipment thermal efficiency.

Labor Cost

- Cost Composition: Includes salaries for operators, technicians, and management staff. It also includes training costs for improving employee work skills.

- Influencing Factors: Local labor market salary levels and the skill requirements of the pyrolysis plant personnel.

- Optimization Plan: Implement automation technology to replace some manual operations, reducing labor intensity and skill requirements.

Maintenance Cost

- Cost Composition: Includes costs for regular inspections, repairs, and technological upgrades of equipment. It also includes emergency repair costs for unexpected breakdowns.

- Influencing Factors: Equipment usage frequency, equipment quality, and operational proficiency.

- Optimization Plan: Choose high-quality equipment and perform regular upgrades to reduce maintenance and spare parts replacement frequency.

How Cutting-Edge Technology Reduces Pyrolysis Plant Cost?

Equipment Cost Saving

Energy Cost Saving

Labor Cost Saving

Maintenance Cost Saving

BLJ-20: Integrated Pyrolysis & Distillation

BLJ-20 batch pyrolysis plant combines pyrolysis and distillation functions, utilizing fractionation technology to separate and collect naphtha and non-standard diesel. This eliminates the need for separate distillation equipment, allowing a single unit to serve two purposes, reducing energy consumption and operating costs, while increasing the added value and economic benefits of fuel products.

BLL-30: Hot Air Heating & Flue Gas Recycling

80% high-temperature flue gas in the furnace is reintroduced into the combustion chamber. It is evenly mixed with the high-temperature hot air from the burner for heating the reactor. 20% high-temperature flue gas is used to heat the combustion air in the hot blast furnace. This waste heat recovery technology saves 55% of energy consumption and significantly reduces exhaust emissions.

BLL-30: Automatic Temperature Control

BLL-30 is equipped with a multi-media automatic combustion valve block and a hot air recycling temperature control system, achieving precise temperature control within ±10°C. The highly automated design requires only two operators, reducing labor intensity by approximately 80% and significantly reducing pyrolysis plant cost estimate for labor.

BLL-30: Oil Gas Spray Condensation

This technology prevents secondary polymerization of olefin compounds, eliminating oil and gas pipeline blockages and downtime for maintenance. This significantly improves condensation efficiency and system stability, enabling continuous operation for 30 days without downtime, thereby reducing maintenance frequency and associated pyrolysis equipment cost.

Beston Group: Reliable Manufacturer for Cost-Effective Pyrolysis Solutions

End-to-End Quality Control

- Strict Material & Component Selection: The manufacturing process uses steel materials that meet international standards. All auxiliary components are sourced from top brands. This ensures the structural strength and durability of the equipment.

- Full Lifecycle Quality Inspection: We implement multi-stage quality inspections. Specific inspections include airtightness, pyrolysis reactor circular runout, and ultrasonic testing. This ensures equipment safety and reliability.

Strong R&D Capabilities

- Technical Team: Beston Group R&D team has over 50 experienced engineers. More than 80% of them have over 10 years of industry experience. They cover a wide range of fields, including mechanical design, materials science, and automation control.

- Strong Sites and Facilities: Our R&D base is equipped with modern laboratories and pilot plants. This supports routine testing and the development & validation of new technologies. Multiple dedicated R&D areas provide technical support for various projects.

EPC Engineering Support

- Full Construction: Customers only need to obtain a valid land survey report for the industrial site. Beston Group will undertake the construction of the entire park. This includes but is not limited to the construction of factory buildings, office buildings, and campus roads.

- Project Schedule Optimization: EPC, a turnkey project, provides customers with convenience. This support can expedite the commissioning of customers’ pyrolysis plant. It also reduces the pyrolysis plant cost for development and construction self-built facilities.

Integrated Service Support

- Pre-sales Service: We provide customized product configuration solutions, invite customers to visit our production site, and fully explain the work process.

- In-sales Service: We provide timely feedback on production progress to ensure trouble-free delivery and transportation. We also assist customers in preparing for civil engineering work in advance.

- After-sales Service: Our engineers provide guidance on installation and commissioning, and offer professional training. We also provide spare parts and regular maintenance services.

Pyrolysis in Global – Reasonable Prolysis Plant Price + One-stop Installation

At Beston Group, we are dedicated to providing efficient and cost-effective pyrolysis solutions for our customers. With advanced technology and precise engineering design, we help customers optimize costs and improve operational efficiency. The following case showcase how we successfully support clients across various industries in turning waste into energy through innovative equipment and tailored services.

In the End

Pyrolysis plant cost is a pivotal factor in shaping the future of waste recycling projects. By understanding the different cost components, investors can make informed decisions that not only optimize their budgets but also drive sustainable success. If you’re considering a pyrolysis plant investment, now is the time to carefully assess your options and choose Beston Group solutions. We can ensure both economic and environmental benefits for you. For more information on pyrolysis recycling, follow us on LinkedIn.