Plastic pyrolysis plant is emerging as a transformative solution in addressing the global plastic waste crisis. This advanced technology enables the conversion of waste plastics into valuable fuel oil through advanced catalytic pyrolysis process. As the world seeks sustainable methods to combat plastic pollution, plastic pyrolysis machine stands out as a promising solution. It creates alternative energy options and mitigates environmental impact. Read on, you will learn the technological advancements of this modern equipment in plastic recycling field.

Acceptable Plastic Types for Plastic Pyrolysis Plant

As a high molecular polymer, plastics come in many different types. Therefore, waste plastics are generated in various industries. However, not all plastics are suitable for waste plastic pyrolysis plant. The following is an analysis of common plastic types and their suitability for plastic to oil plant:

PET

- Oil Yield: 0%;

- Sources: transparent bottles, mechanical parts, fiber products, etc.

- Feature: The oxygen produced by the reaction poses a safety hazard.

HDPE

- Oil Yield: 85%~95%;

- Sources:daily necessities containers, pipe fittings, household items,etc.

- Feature: high tensile strength, corrosion resistance.

PVC

- Oil Yield: unstable;

- Sources: wire insulation, municipal pipes, outdoor building materials, etc.

- Feature: oil obtained from PVC contains chlorine. Burning oil produces dioxins.

LDPE

- Oil Yield: 85%~95%;

- Sources:packaging films, bags, disposable tableware, etc.

- Feature: low strength, good flexibility, easy collection

PP

- Oil Yield: 80%~90%;

- Sources:food packaging, medical supplies, household products, etc.

- Features: good heat resistance, chemical corrosion resistance.

PS

- Oil Yield: 80%~90%;

- Sources: disposable tableware, lightweight casings, crafts, etc.

- Features: Good formability, meets food grade certification standards.

ABS

- Oil Yield: 40%;

- Sources: Electrical appliance shell, daily necessities, advanced toys, etc.

- Features: good mechanical properties, easy to paint and print.

Note:

- Plastics containing halogen elements and oxygen elements are not recommended for pyrolysis treatment;

- We can assist in testing the plastics you have and determine the feasibility of the project;

- The simpler the type of plastic, the purer the plastic, the higher the pyrolysis oil yield.

Here are some common plastic oil yields for your reference:

How a Plastic Pyrolysis Machine Works?

01 Plastic Material Feeding

- Use a hydraulic feeder or a screw feeder (for plastic pellets after granulation) to feed the plastic raw materials into the equipment. Subsequently, remove the feeder and close the locked furnace door.

02 Plastic Pyrolysis Oil Collection

- Start the main furnace and preheat it. Fuel options include diesel, natural gas, heavy oil or pyrolysis oil.

- After preheating, feed the material. Then, when the temperature of the plastic pyrolysis reactor rises to about 100°C, the plastic is thermally decomposed to produce oil gas.

- Next, the high-temperature oil and gas enter the catalytic tower. Then, it contacts the catalyst and bauer porcelain rings.

- After passing through the catalytic tower, the high-temperature oil gas enters the condenser. Finally, it condenses into liquid oil and enters the oil storage tank.

03 Gas Recovery

- Syngas: Uncondensed syngas re-enters into the burner as heating fuel for the plastic pyrolysis plant, saving fuel consumption.

- Flue Gas: For hot air heating system, high temperature flue gas re-enters the combustion chamber for waste heat utilization.

04 Waste Gas Treatment

- Exhaust gas generated from plastic pyrolysis process first enters the flue condenser for cooling.

- The cooled flue gas enters the spray tower for dust removal and then is discharged into the atmosphere through the chimney.

- We provide high-end exhaust gas treatment system. The flue gas treated by this system can meet EU emission standards.

05 Solid Residue Discharge

- After the pyrolysis process is completed, the burner is turned off, the main furnace and the fan continue to operate, and the temperature is naturally reduced for 7-8 hours.

- Discharge the solid residue using water-cooled screw conveyor. If you want to achieve rapid cooling, we provide a multiple screw conveyor solution.

Plastic Pyrolysis Plant Creates Multiple Value: 3 Types Oil Collection

Plastic pyrolysis machine initially produces a broad-range hydrocarbon mixture, commonly referred to as catalytic pyrolysis oil. Through distillation, this oil can be separated into different fractions, including no-standard diesel and naphtha, each with distinct properties and application pathways.

Catalytic pyrolysis oil:

a wide-boiling-range mixture with higher aromatic content, typically used directly as an industrial fuel after basic conditioning.

No-standard diesel:

with diesel-range carbon distribution, suitable for energy applications but not compliant with on-road fuel standards.

Naphtha:

a light hydrocarbon fraction with narrow boiling range, suitable for material recycling and petrochemical feedstock applications.

For Energy Recovery

- Catalytic pyrolysis oil: used as an alternative fuel in industrial furnaces or boilers in cement plants, steel plants, and heavy industrial parks.

- No-standard diesel: used as a substitute fuel for heavy-oil power generation units.

- No-standard diesel: used as a driving fuel for heavy-duty machinery, including mining equipment, construction machinery, and port handling equipment.

For Material Recycling

- Naphtha: used as feedstock for petrochemical steam crackers to produce base olefins for new plastics and synthetic rubber manufacturing.

- Naphtha: further refined and used as a gasoline blending component to improve volatility and combustion performance.

- Naphtha: used as a solvent or chemical feedstock in fine chemical applications such as coatings, inks, and industrial cleaning agents.

Naphtha: The Breakthrough Point in Plastic Pyrolysis Controversies

Since plastic pyrolysis plant moved toward industrial-scale deployment, three core controversies have persisted: Is This Incineration or Not? Does Pyrolysis Qualify as Recycling? Is Pyrolysis Project Actually Profitable? These debates often overlap in technical and regulatory discussions. However, from an engineering and market perspective, they all point to one key metric—the yield of light naphtha.

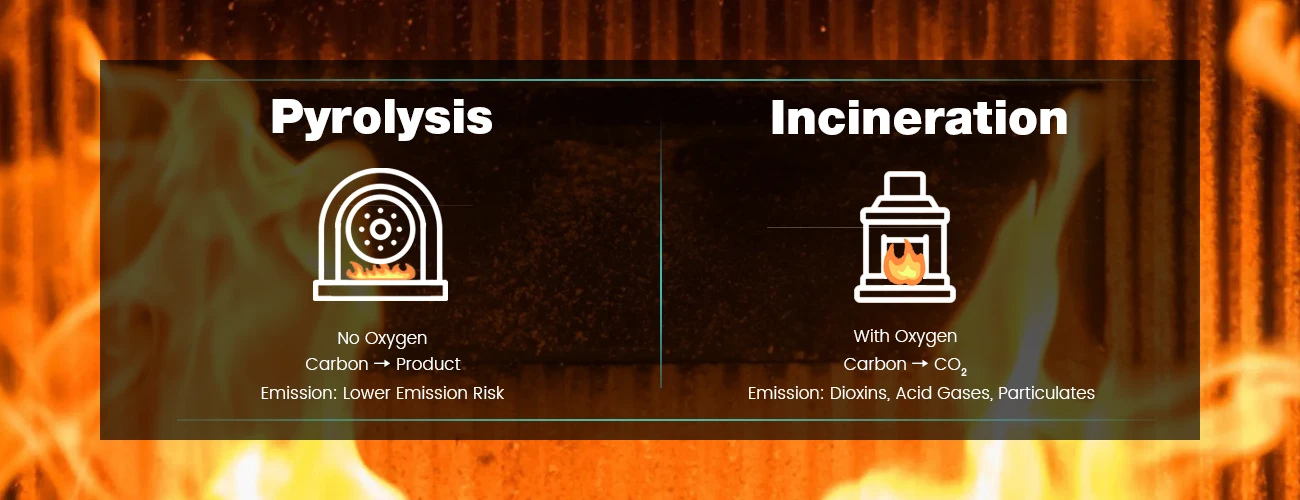

1. Is This Incineration or Not?

2. Does Pyrolysis Qualify as Recycling?

3. Is Pyrolysis Project Profitable?

In regulatory assessment and carbon footprint accounting, the key issue is not “combustion” itself, but whether plastic carbon directly enters the emission system.

- Incineration: Plastic carbon is almost entirely converted into carbon dioxide and released immediately. The carbon footprint is concentrated and irreversible. It also tends to generate dioxins, acidic gases, and particulate matter.

- Plastic pyrolysis: Part of plastic-derived retained in naphtha doesn’t enter the emission system in lifecycle. When used as fuel, the plastic-derived carbon is relatively pure in composition, which significantly reduces emission risks.

Therefore, the higher the naphtha yield, the lower the proportion of carbon entering the emission system. The carbon footprint boundary between pyrolysis and incineration becomes clearer.

Whether pyrolysis qualifies as chemical recycling, under EU and certain regulatory frameworks, depends not on the process itself but on how the products are used.

- Material recycling: Light naphtha enters steam crackers or chemical plants as feedstock to regenerate plastics, synthetic rubber, or basic chemicals. This pathway can be recognized as chemical recycling.

- Energy use: If pyrolysis products are mainly used for combustion, they cannot be classified as recycling but as energy use. Such oils usually cannot achieve End-of-Waste (EoW) status.

Therefore, the higher and more stable the naphtha yield, the clearer the recycling attribute. Low or unstable yields make it difficult to move beyond energy use or waste classification.

The profitable viability of plastic pyrolysis projects also depend on the output structure and compliance attributes of naphtha.

- High-value commercialization pathway: Naphtha can obtain sustainable feedstock attributes through certifications such as ISCC, enabling entry into mainstream petrochemical and brand supply chains with higher value recognition.

- Low-value disposal pathway: If products are mainly used as fuels, their commercial value remains limited. Projects also face higher uncertainty and compliance costs within regulatory and certification systems.

Therefore, producing naphtha with clear recycling attributes creates access to high-value markets for investors and operators. It allows projects to balance economic performance with long-term sustainability.

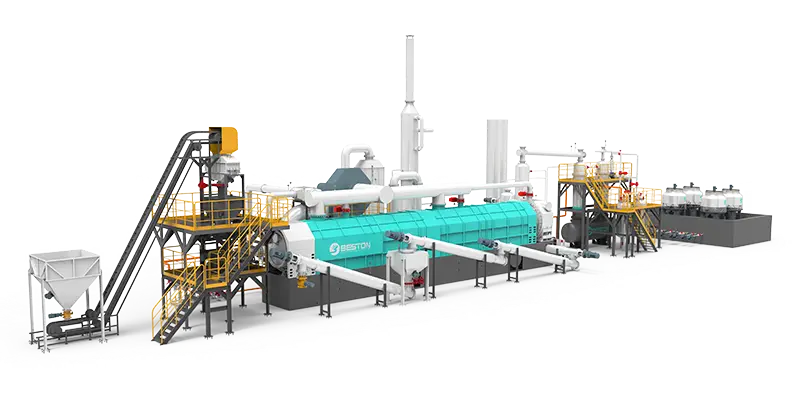

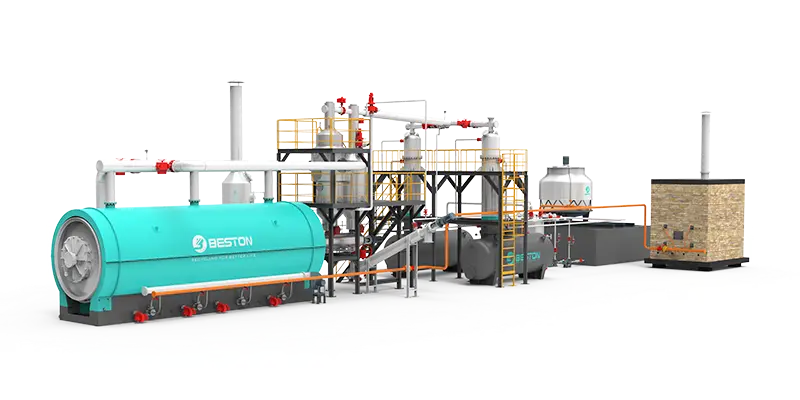

3 Models of Plastic Pyrolysis Plant for Sale

The plastic pyrolysis machine realizes the multi-phase resource collection of waste plastics, including plastic pyrolysis oil, syngas, and industrial residue. It is an integrated equipment including multiple systems such as feeding, reaction, condensation, discharge, and gas treatment. From the perspective of composition structure, the machine can be divided into 2 categories: continuous and batch type. The following is parameter table and main component diagram for your reference.

Continuous Type: BLL-30

- Process 6,000 tons waste plastic annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

Batch Type: BLJ-20

- Process 4,000 tons waste plastic annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons waste plastic annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

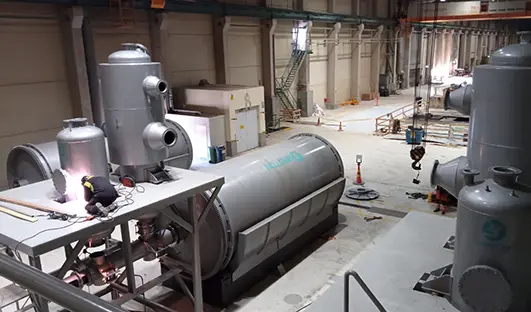

Successful Case in Europe: ISCC-Certified Oil Production

Corsair Group is at the forefront of plastic waste chemical recycling. With operations across Europe and Asia, the company focuses on scalable solutions to address plastic waste and advance circular plastics. By deploying plastic pyrolysis equipment supplied by Beston Group, Corsair produces pyrolysis oil that is fully certified under ISCC PLUS. The project establishes a certified circular feedstock pathway and sets a benchmark for plastic pyrolysis recycling projects in Europe.

Project Information

- Project Start Date: May 2024

- Acceptance Date: October 2025

- Configuration: 3 set of BLJ-16 plastic to fuel machines with catalytic system

Project Status

- Plastic Processing Capacity: 24-30 tons per day

- Oil Application: Sold to oil refineries. After further processing, used as raw material for recycled plastics production.

- Future Plan: Expand processing capacity to 70 tons/day

Plastic Catalytic Pyrolysis Technology – 200% Efficiency Boost

Plastic catalytic pyrolysis is a technology that solves the wax oil blockage problem through the action of a catalyst. This technology introduces a catalytic tower at the manifold. Molecular sieve catalysts and Bauer ceramic rings are placed in the catalytic tower. Oil gas from the pyrolysis reactor contacts it. The catalytic action not only solves the wax decondensation and liquefaction problem, but also increases the reaction efficiency 200%. This technology creates the following core values:

Optimize Project ROI

- Increase Oil Value: Wax oil is a long-chain hydrocarbon, which is easy to solidify and clog in pipeline. After catalytic liquefaction, it forms a low-freezing point light oil product. It has higher calorific value, better clarity, and higher market value.

- Low Maintenance Cost: Removing wax oil avoids maintenance and shutdown of plastic pyrolysis plant. This significantly reduces maintenance frequency and labor costs. Meanwhile, it reduces production capacity losses caused by downtime.

Improve Safety Performance

- Prevent Overpressure Risk: There is no wax or oil solid deposition in the pipeline. Therefore, the system pressure is stable and controllable. This avoids the risk of sudden pressure increase, pipeline rupture or leakage caused by blockage.

- Eliminate Local Overheating: There is no wax attached to the pipeline wall. Therefore, the system temperature is evenly distributed. This reduces the thermal stress and fatigue damage of components caused by local high temperature.

Cutting-Edge Technology of Plastic Pyrolysis Plant

Technological Innovation of BLJ-20

Technological Breakthrough of BLL-30

50% Higher Throughput

The ø2800×10000 reactor of BLJ-20 plastic pyrolysis plant increases daily processing capacity. The plastic processing capacity has been upgraded from 8 tons per day to 12 tons per day. Higher throughput improves productivity and makes waste conversion more efficient and reliable.

One-Step to Get Two Oil

Integrated fraction distillation separates naphtha (<200 °C) and non-standard diesel (>200 °C) in a single process. It improves oil quality, increases market value. Meanwhile, this design reduces operational costs by eliminating extra equipment and saving energy.

Maximum Safety & Comfort

Advanced sealing and high-temperature insulation prevent oil vapor leaks and eliminate open flames. Therefore, thermal hazards are minimized. This design ensures safe, stable, and comfortable operation, reducing risk and supporting continuous production.

30-Day Continuous Operation

In BLL-30 plastic pyrolysis plant, oil-gas spray condensation technology rapidly lowers temperature. It prevents olefin polymerization and avoids pipeline blockage. Thus, this design increases condensation efficiency and supports continuous operation for 30 days without shutdown.

55% Fuel ↓, 50% Emission ↓

A stainless-steel induced draft fan recycles 80% hot flue gas back to the combustion chamber. Mixed with 1000–1300 °C hot air, it efficiently heats continuous pyrolysis reactor. The remaining 20% preheats fresh air. This design saves 55% fuel and reducing exhaust emissions by 50%.

80% Less Manual Work

Automatic combustion valves and hot air recirculation precisely regulate furnace temperature within ±10 °C. The system adapts to various fuels, stabilizes heating conditions. Combined with continuous feeding and discharging, this design reduces manual adjustments by 80%.

Investment Opportunities in Plastic Pyrolysis Machine Across Industries

Plastic Products Processing

- Promote Circular Economy: Pyrolysis oil, as a clean energy, can be directly used as fuel in the processing of plastic products, replacing traditional energy sources. Thus, this reduces the energy cost and carbon footprint of enterprises. Waste plastics re-enter the production cycle through pyrolysis, promoting the circular economy of the plastic industry.

- Promote Industrial Linkage:Plastic pyrolysis plant can provide alternative raw materials for polymer production and re-enter the resource cycle. This “product” to “raw material” model promotes resource sharing in the upstream and downstream industries of plastics. Such a two-way cooperation helps promote the green transformation of the entire plastic industry chain.

Domestic Waste Disposal

- Reduce Land Occupation: The domestic waste treatment industry has traditionally relied on landfilling for the treatment of plastics. This method requires a lot of land resources. In contrast, plastic pyrolysis equipment can effectively convert waste plastics into smaller energy or chemicals. Therefore, this avoids occupying a large amount of land for stacking or disposal.

- Reduce Plastic Pollution: In the traditional landfill or incineration process, waste plastics often fail to be effectively utilized as resources, resulting in the long-term existence of pollution sources. Plastic pyrolysis technology avoids the risk of plastic pollution entering the natural environment. This promotes the waste treatment industry to develop in a greener direction.

Plastic Recycling Center

- Broaden Recycling System: The existing waste plastic recycling system has limited effect on some waste plastics that are difficult to recycle or have low value. After the introduction of waste plastic pyrolysis machine, these waste plastics can be converted into valuable pyrolysis products. Thus, this broadens the recycling channels and improves the overall recycling rate.

- Broaden Income Channels: The income of traditional recycling centers mainly depends on the recycled waste plastic raw materials. Under the effect of pyrolysis technology, the recycling center can turn the difficult-to-recycle waste plastics into valuable resources. This not only increases the source of income, but also further improves profitability by selling these by-products.

How Plastic Pyrolysis Plant Meets Policy Challenges

As global environmental policies continue to tighten, plastic pyrolysis process is becoming a key technology to cope with policy challenges and promote green transformation. The following are the specific advantages of plastic pyrolysis machine in the face of environmental regulations and policy challenges:

Accelerate Global Emission Reduction

Plastic pyrolysis meets the needs of more and more environmental regulations through the process of efficiently converting waste plastics into energy.

- The EU’s carbon emission trading system (EU ETS) encourages the use of low-carbon technologies, and pyrolysis technology has become an effective tool for enterprises to reduce emissions by reducing GHG emissions when incinerating plastic waste.

- Plastic pyrolysis equipment meets environmental protection standards by reducing greenhouse gas emissions. This can bring carbon offsets to enterprises. It earns revenue in the carbon trading market and helps enterprises reduce carbon tax costs.

Relieve Corporate Policy Pressure

Enterprises are facing increasingly severe environmental compliance pressure. Fortunately, plastic pyrolysis technology provides solutions that comply with environmental regulations.

- Pyrolysis converts waste plastics into renewable energy. This not only helps companies effectively reduce the impact of plastic waste on the environment. The technology can also reduce corporate processing costs and increase resource utilization efficiency.

- The government is paying more and more attention to plastic processing. If companies fail to handle waste plastics in accordance with regulations, they may face high fines and tax penalties. Pyrolysis technology effectively avoids these potential risks.

Promote Green Transformation

Plastic pyrolysis technology is highly consistent with the strategic direction of promoting green economy and low-carbon technology in countries around the world:

- Plastic pyrolysis technology can promote the use of clean energy, reduce dependence on traditional fossil energy, and provide new impetus for technological innovation in industries such as energy, environmental protection, and circular economy.

- Pyrolysis is also continuing to promote the development of a low-carbon economy, helping companies and countries cope with global climate change, and promoting the sustainable development of energy, environmental protection, and circular economy.

Positive Policy Signals on Plastic Pyrolysis

EU: The First Unified Legal Framework for Chemical Recycling Recycled Content

EU Rules for Calculating, Verifying and Reporting Recycled Plastic Content under the Single-Use Plastics Directive (SUPD) (Draft)

EU is developing Mass Balance–based rules for calculating and verifying recycled content from chemical recycling. This is the first time EU is establishing a unified and auditable regulatory framework for how chemically recycled materials may count as “recycled content.” The draft focuses on harmonized accounting methods, auditing procedures, and traceability requirements, laying the foundation for the formal integration of chemical recycling into EU’s regulatory system.

France: End-of-Waste Criteria for Plastic Pyrolysis Oil Officially Established

Order of 19 February 2024 Establishing End-of-Waste Criteria for Plastic Pyrolysis Oil Used as Feedstock in Steam Cracking Units

France issued a dedicated ministerial order establishing clear conditions under which plastic pyrolysis oil can attain End-of-Waste (EoW) status—meaning it is no longer classified as waste—once stringent quality and traceability requirements are met. This is one of the first comprehensive national regulatory frameworks in the EU governing pyrolysis oil EoW certification, representing a significant compliance advantage for chemical recycling operators.

UK: Chemical Recycling Included in Plastic Packaging Tax (PPT) Recycled Content Calculation

Plastic Packaging Tax — Mass Balance Accounting for Chemically Recycled Plastic (HMRC Policy Update)

The UK has confirmed that Mass Balance accounting will be permitted to calculate recycled content from chemical recycling within the Plastic Packaging Tax (PPT) framework, with implementation planned for 2027. This means chemically recycled feedstocks that meet traceability and verification requirements will carry direct fiscal value, incentivizing brands and packaging companies to procure compliant chemically recycled materials.

Why Choose Beston Group as Your Plastic Pyrolysis Plant Manufacturer?

Strong R&D Capabilities

- Experienced Team: Beston’s R&D team consists of over 50 skilled engineers. The majority have over 10 years of industry experience. Their expertise spans mechanical design, materials science, and automation control.

- Advanced Facilities: Our R&D center features modern laboratories and pilot plants. These facilities support both routine testing and the development of innovative technologies.

End-to-End Quality Control

- Premium Materials & Components: We use high-quality steel materials meets international standards. All components are from top-tier brands, ensuring durability of plastic pyrolysis plant.

- Comprehensive Inspections: Multiple quality checks are performed throughout the production process. These include airtightness tests, reactor assessments, and ultrasonic testing to ensure the safety and functionality of the equipment.

Integrated Service Support

- Pre-sales Assistance: We provide tailored product configurations. Customers are welcome to visit our production site.

- In-sales Updates: We keep customers informed about progress. We also assist with preparation for civil engineering work.

- After-sales Care: Our engineers guide installation and commissioning. We also offer professional training support.

EPC Engineering Support

- Complete Construction Services: Beston handles the entire construction process, including factory buildings, office structures, and infrastructure. This starts with a valid land survey report.

- Efficient Project Delivery: Our EPC service accelerates the commissioning of plastic pyrolysis equipment. It also cuts down on costs compared to developing self-built facilities.

Contact Beston to Get Plastic Pyrolysis Solution and Machine!

Beston plastic pyrolysis plant environmentally converts these waste plastics into usable pyrolysis oil and other by-products. Beston Group aims to be a provider of plastic recycling solutions. We have established partnerships with multiple companies and are committed to sustainable development and mitigating climate change by implementing a circular economy for plastics. This chemical recycling method achieves recovery of plastics and provides them with a second life cycle. Want to learn more about plastic pyrolysis? Follow us on LinkedIn.