Charcoal making machine provides a cutting-edge solution for efficient biomass recycling. As a technology partner of Puro.earth, Beston Group BST-50S equipment meet the highest standards in carbon sequestration, contributing to biochar carbon removal projects. With a proven track record of successful project worldwide, Beston charcoal machine not only enhances environmental sustainability but also creates additional income opportunities for customers by utilizing biomass waste efficiently.

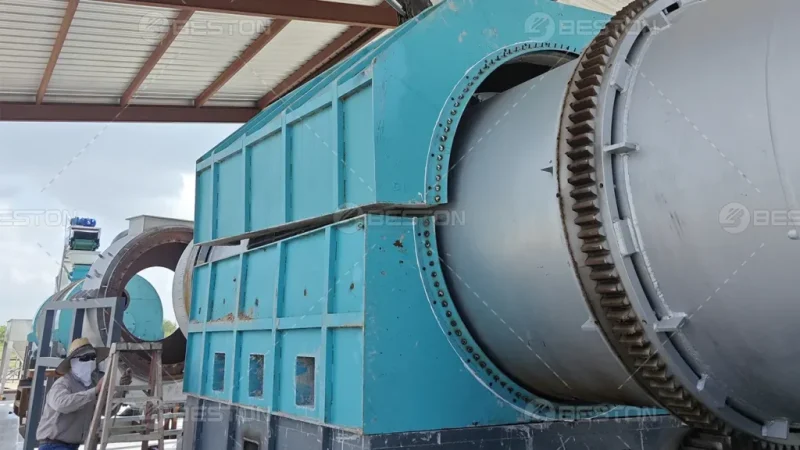

Successful Case: Shisha Charcoal Production Project in Southeast Asia

Project Information

- Project start date: July 1, 2023

- Commercial operation date: July 31, 2024

- Configuration: Feedstock pretreatment system + pyrolysis system + forming system

- Feedstocks: Coconut shells, palm shells, rice husks

Project Status

Since delivery in July 2024, the equipment has been operating smoothly:

- Operating performance: Processing capacity of up to 3 tons per hour, enabling continuous operation at 5×24 hours

- Project impact: Created 30 local jobs and contributed to local economic development

Models & Parameters of Charcoal Machine for Sale

Commercial Scale: BST-50

- 6,000 tons charcoal production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

- BST-50S technology vetted by puro.earth

Testing Scale: BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon sink process verification

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

How BST-50S Charcoal Machine Adds Value After Puro.earth Evaluation?

- Ensure Technical Compliance: BST-50S provides a verified technical solution for the project. This helps ensure the project meets global carbon removal standards during implementation, reducing compliance risks.

- Reduce Certification Uncertainty: BST-50S offers transparency and verifiability in technology. This makes it easier for the project to undergo carbon credit certification with fewer technical reviews and modifications.

- Lower Verification Costs: With the vetted BST-50S biochar machine, its efficiency and stability for CDR projects are confirmed. This eliminates the need for additional costs in technology verification or solution optimization.

- Speed Up Implementation: BST-50S charcoal making machine allows the project to move into the implementation phase faster. This shortens the overall project timeline and helps clients secure carbon credits in a shorter period.

- Boost Brand Credibility: Using BST-50S model charcoal production machine increases trust and competitiveness in the carbon market. This makes it easier to attract partners and expand market share.

- Expand Market Opportunities: Carbon removal projects with BST-50S significantly enhances the project’s competitive edge. As a result, clients can access more business opportunities and grow their market reach.

Dual Technological Innovations in Charcoal Making Machine

Tar Dust Self-cleaning System

7200H/Y Stable Operation

This technology ensures charcoal machine does not form blockages, thereby achieving continuous operation with excellent performance.

- Insulation: Synergistic insulation prevents volatile organic matter (tar & wood vinegar) from condensing and clogging the system.

- Dust removal: The purge system prevents carbon dust from accumulating in key parts of the system and clogging the system.

Dual-cylinder Rotary Core Kiln

10+m³/h Processing Capacity

Unique dual-cylinder furnace structure enables multi-stage carbonization, which greatly improves operating efficiency of biochar pyrolysis machine.

- Inner cylinder performs intensive drying of the raw biomass to optimize moisture content.

- Outer cylinder carries out complete pyrolysis, maximizing carbon conversion efficiency and biochar yield.

Raw Material for Charcoal Production Machine

Diverse Application of Charcoal in Various Industries

Agriculture & Forestry

- Soil Conditioner: Charcoal can improve soil water retention and nutrient supply. In addition, it not only increases soil organic matter, but also improves soil aeration. It helps the growth of plant roots.

- Seedling Substrate: Used as substrate, charcoal enhances plant disease resistance and growth rate. It promotes oxygen exchange in the roots of seedlings, which is beneficial to growth.

Construction Industry

- Building Materials Additive: Charcoal improves the durability and compressive strength of concrete, bricks and cement mortar. In addition, it improves the thermal insulation properties of buildings.

- Pavement Materials Additive: Charcoal improves the durability and crack resistance of pavement. Thus, it makes asphalt more resilient in the face of temperature changes and high traffic loads.

Animal Husbandry

- Feeding Additive: Charcoal improves the nutritional efficiency of feed while promoting intestinal health. More importantly, charcoal helps reduce methane emissions from rumen animals.

- Bedding Additive: Charcoal absorbs moisture and maintains a dry environment, reducing the growth of odors. In addition, this reduces the spread of pathogens and extends the life of the bedding.

Traditional Industry

- Industrial Fuel: Charcoal has high energy density and stable combustion properties. This makes it a preferred alternative fuel in energy-intensive industrial processes.

- Smelting Reducing Agent: Wood charcoal is often used as a reducing agent. By replacing traditional coke, it effectively reduces the energy consumption of traditional smelting processes.

Solutions Brought by Charcoal Making Machine

Carbon Market Entry

Reduce Carbon Footprint

Closed-Loop Biomass Utilization

- Stabilized CDR Project: The biochar output by charcoal making equipment is highly stable and fully meets the long-term carbon sequestration requirements of the CDR (Carbon Dioxide Removal) project. It ensures that the carbon removal amount can be verified from the source and can generate reliable carbon credits.

- Participate in Carbon Trading: Currently, the technical support and data monitoring system for BCR is mature. Therefore, biochar carbon removal projects can obtain carbon removal credits and stable carbon price. Investors can use expanding global voluntary carbon market to increase project returns and influence.

- Fossil Emissions Reduction: Charcoal machine converts agricultural/forestry waste into clean fuel. It replaces high-carbon energy such as coal and oil, significantly reducing carbon emissions. In addition, this reduces the cost pressure caused by carbon taxes.

- Low-carbon Transformation: Integrating sustainable fuels into the production process drives companies to upgrade from high-emission models to green manufacturing. This enhances brand image while complying with increasingly stringent low-carbon regulations.

- Large-scale Reduction: Charcoal making machine can be deployed directly at the source of biomass waste. It achieves efficient volume reduction and avoids the risk of fermentation, spontaneous combustion and pollution caused by open-air stacking. This reduces the processing burden of enterprises.

- Resource irculation: Biomass pyrolysis fuel can be directly integrated into the energy system of enterprises. In addition, for industries involving wood & crop planting, charcoal can not only promote production. The residue after harvest can be pyrolyzed again, forming a real closed loop of biomass circulation.

Step-by-Step Working Process of Charcoal Machine

01 Raw Material Pretreatment

- Crushing: Raw materials are crushed to less than 20mm to ensure uniformity and smooth flow. Larger fragments are screened out.

- Drying: The moisture content of the raw materials is reduced to below 15%. Excess moisture can lead to unnecessary energy consumption during the charcoal manufacturing process.

02 Pyrolysis

- Water Evaporation: The biomass begins to lose water as temperature rises.

- Volatile Substance Release: Between 200℃ and 500℃, biomass decomposes and releases volatile gases, which are used to heat the charcoal making machine reactor.

- Charcoal Formation: When the temperature exceeds 500℃, the release of volatile substances decreases, and carbon components in the biomass are converted into charcoal.

03 Combustible Gas Utilization

- Gas Collection: After dust removal, the combustible gases are collected and directed back into the combustion chamber as fuel. Insulated systems prevent the formation of tar and wood vinegar, which can clog pipes.

- Excess Gas Burning: Any excess combustible gas is directed to the exhaust combustion chamber for further burning.

04 Flue Gas Recovery

- Air Preheating: High-temperature flue gases are used in an air-to-air heat exchanger to preheat the air for the burner, improving combustion efficiency.

- Material Drying: The remaining flue gases are directed to the drying furnace, where they are used to dry the raw materials, reducing energy consumption.

05 Discharge

06 Exhaust Gas Treatment

Technical Highlights of Charcoal Making Machine

Advanced Combustion System

- Methane Control: The closed combustion chamber of carbonization furnace keeps methane emissions exceptionally low (<0.1% of the carbon stored in charcoal).

- Low-Nitrogen Combustion: Equipped with a low-nitrogen combustion burner, nitrogen oxide emissions are minimized, representing less than 1% of the carbon stored in charcoal.

Precise Temperature Control

- Centralized PLC Control: Precise regulation of temperature, pressure, and airflow ensures optimized control of key process parameters.

- Variable Frequency Fan Application: Adjustable airflow and gas velocity enhance pyrolysis uniformity and thermal efficiency of the charcoal machine.

Safety Guarantee

- Explosion-Proof Design: Charcoal making machine features explosion-proof holes and seals that prevent safety hazards caused by excessive system pressure.

- Dynamic Sealing: A multi-layer sealing system, combining various materials, ensures better sealing, preventing gas leakage and improving overall safety.

Strict Emission Control

- Multi-Stage Dust Removal: A multi-stage cyclone dust collection system installed at the dryer, feed port, and piping effectively captures dust, ensuring a clean operational environment.

- High-End Exhaust Gas Treatment: Exhaust gases undergo multi-stage processes such as dust removal, adsorption, and desulfurization. This ensures that emissions comply with stringent EU standards.

Projects of Beston Charcoal Machine All over the World

Partner with Beston Group

By partnering with Beston Group, businesses gain access to state-of-the-art charcoal making machine designed for efficient and sustainable biomass recycling. Our expertise in advanced pyrolysis technology and global presence ensures customers can maximize their resource recovery while minimizing environmental impact. With our commitment to innovation and sustainability, you can confidently scale up your recycling operations and contribute to a greener future. For more news on carbon removal, follow us on LinkedIn.