By converting plastic/oil sludge/tyre/biomass—into high-value resources, pyrolysis plant offers a sustainable alternative to traditional landfilling or incineration. Innovations in pyrolysis technologies have bridged the gap between strict environmental compliance and long-term operational profitability. Through this multi-benefit solution, project developers and sustainability-focused investors can effectively de-risk their waste management strategy. Such a system also allows them to gain a competitive advantage in the global transition to a carbon-neutral economy. Want to learn about the recycling potential of pyrolysis machine? Please read on.

4 Solutions Provided by Pyrolysis Plant

Plastic Catalytic Pyrolysis

Oil Sludge Harmless Treatment

Tyre rCB Production

Biochar Carbon Sequestration

Wax Oil Catalytic Liquefaction Technology Increases Production Efficiency by 200%

Raw Material Types:

Waste plastics such as PE/PP/PS (excluding PVC/PET)

Solution:

Waste plastics to catalytic pyrolysis oil/non-standard diesel/naphta

Technology Highlights:

- Pipe blockage prevention minimizes operational risks

- ISCC-certified oil production

Thermal Water Washing + Pyrolysis Combination Process Boosts Production Efficiency by 200%

Raw Material Types:

Oily waste such as contaminated soil, drilling cuttings, tank bottom sludge, etc.

Solution:

Oily sludge to pyrolysis oil/non-hazardous residue

Technology Highlights:

- Anti-caking to improve thermal efficiency in pyrolysis machine

- Combined process maximizes waste utilization value

High-value Utilization of Carbon Black Achieves Fivefold Revenue Increase

Raw Material Types:

Passenger tires, commercial tires, engineering tires, and other waste rubber products

Solution:

Waste tires to pyrolysis oil/rCB

Technology Highlights:

- Precise temperature control in the pyrolysis reaction reduces TPH

- Elevating carbon black specific surface area through grinding/granulation for N550/N660 preparation

Annual Output of 6,000 Tons of Biochar, 12,000 Tons of Carbon Sequestration

Raw Material Types:

Waste wood, fruit shells, agricultural residues, and other waste biomass

Solution:

Waste biomass to biochar

Technology Highlights:

- Safe & stable operation: 7200+ hours per year

- High-quality biochar meets EBC standards

- Low air pollutants/GHG emissions

Global Impact: Pyrolysis Machine Delivering Real Results

Plastic Pyrolysis Project in Finland

Oil Sludge Treatment in Oman

Wood Pyrolysis Project in Spain

Project Information

- Location: Jämsä, Finland

- Delivery Duration: 8th May 2024 – 29th Oct 2025

- Project Configuration: 3 sets of BLJ-16 plastic pyrolysis machine

- Processing Capacity: 4,000 tons/year*3=12,000 tons/year

- Plastic Pyrolysis Oil Use: Sold as chemical raw materials

Project Status

- Installation & Commissioning: Equipment installation, commissioning, and operation training completed.

- Outstanding Achievements: The project’s oil products have successfully obtained ISCC-Plusren certification.

- Future Development: Establish strategic partnerships with clients. Phase 2 of project increased to 10 sets.

Project Information

- Location: Sohar, Oman

- Delivery Duration: 21th May 2023 – 10th Dec 2024

- Project Configuration: 2 sets of BLJ-16 pyrolysis units, 1 set of BLJ-3

- Processing Capacity: 10 tons/day

- Profit Channels: Earn oil sludge disposal fees

Project Status

- Installation & Commissioning: Equipment installation, commissioning, and operation training completed.

- Outstanding Achievements: Co-host technical exchange with Beston Group enhanced brand influence in the Middle East.

- Future Development: Expand production capacity. Become a benchmark oil sludge treatment center in the region.

Project Information

- Location: Malaga, Spain

- Delivery Duration: 28th Jan 2023 – 5th Mar 2024

- Project Configuration: 1 set of BST-50 biochar equipment

- Processing Capacity: 24 tons/day

- Profit Channels: Biochar carbon credits for sale

Project Status

- Installation & Commissioning: Equipment installation, commissioning, and operation training completed.

- Outstanding Achievements: Co-host technical exchange with Beston Group enhanced brand influence in the Europe.

- Future Development: Expand production capacity. Broaden the carbon credit sector into the building materials industry.

Parameters of Pyrolysis Plant for Sale

BLJ-16 & BLL-30: For Plastic/Oil Sludge/Tyre

BST-06 & BST-50: For Biomass

Continuous Type: BLL-30

- Large-scale processing choice

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

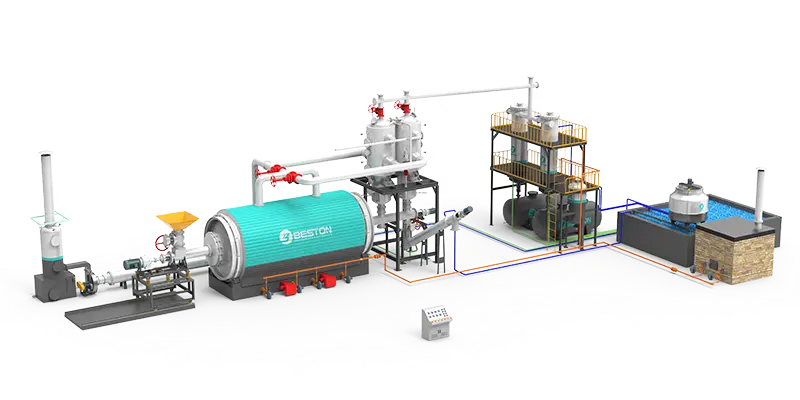

Batch Type: BLJ-20

- Large-capacity Pyrolysis Reactor (ø2800*10000)

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Small processing choice

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Materil | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

Commercial Scale: BST-50

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

- BST-50S technology vetted by puro.earth

Testing Scale: BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon sink process verification

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Pioneering Technological Advances in Pyrolysis Plant

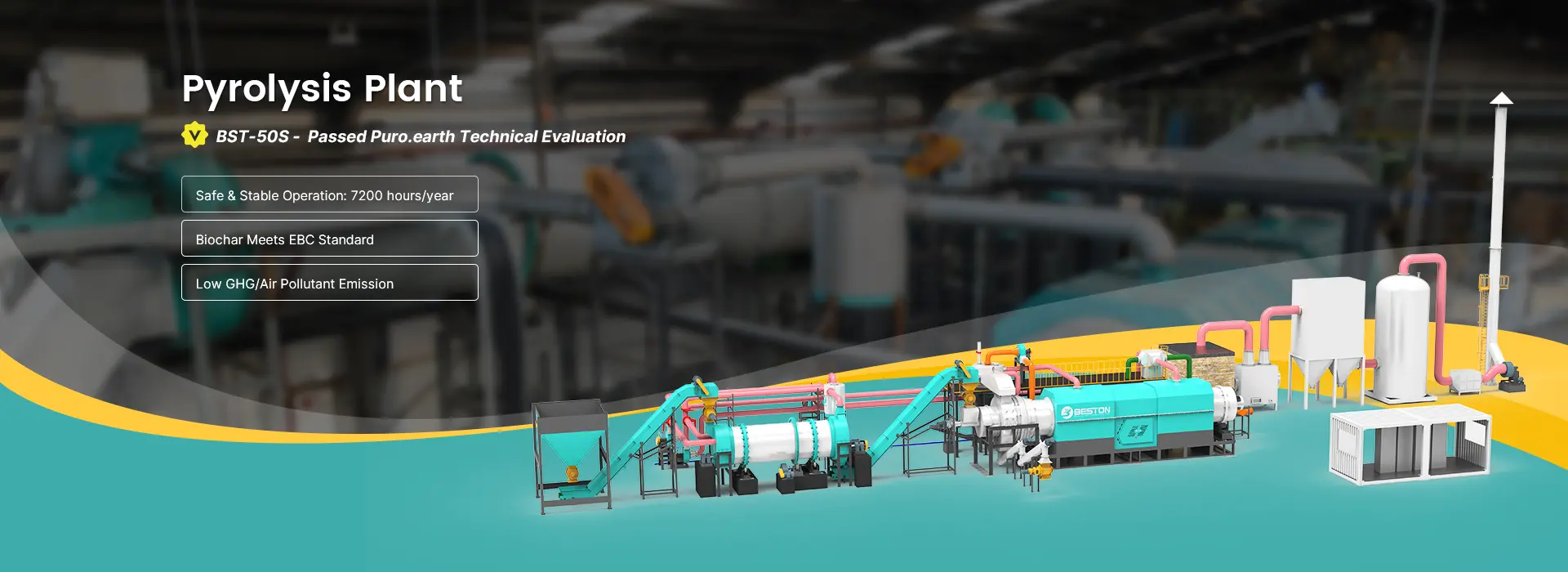

BST-50S: Puro.eath Technical Vetted

BLL-30: High Automation Production

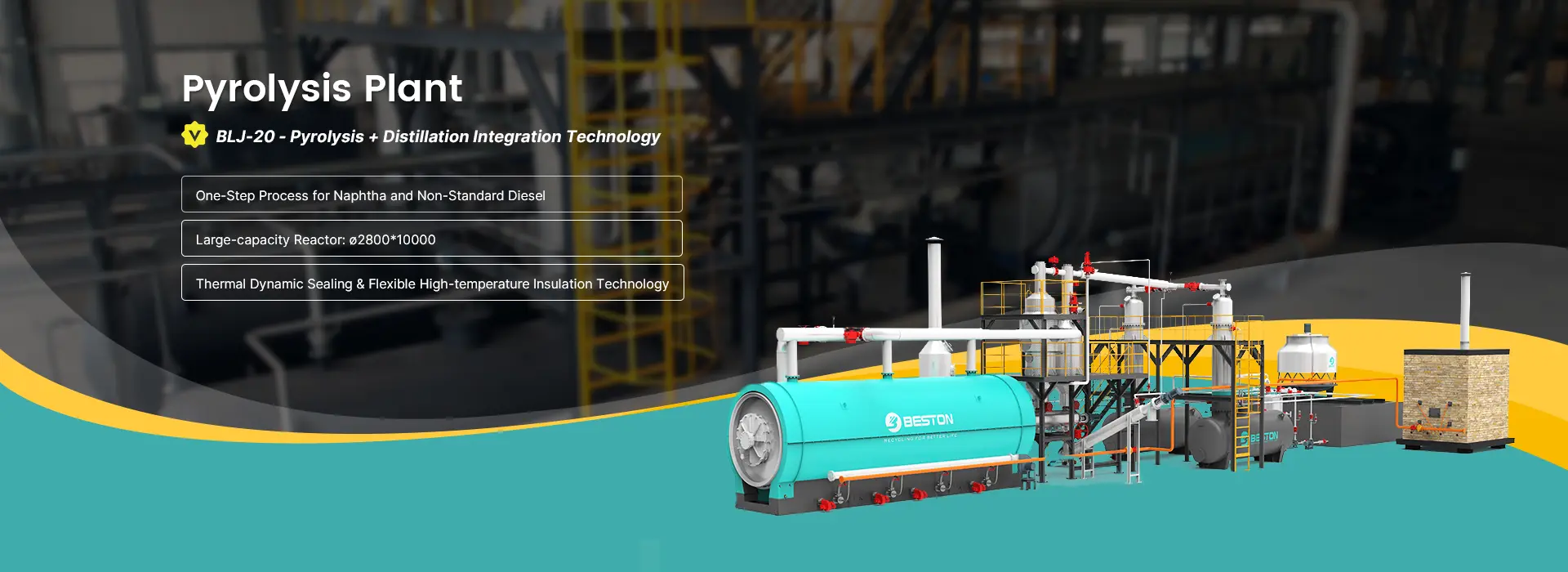

BLJ-20: Pyrolysis+Distillation Integrated

Tar Dust Self-cleaning System

7200H/Y Stable Operation

This technology ensures pyrolysis plant does not form blockages, thereby achieving continuous operation with excellent performance.

- Insulation: Synergistic insulation prevents volatile organic matter (tar & wood vinegar) from condensing and clogging the system.

- Dust removal: The purge system prevents carbon dust from accumulating in key parts of the system and clogging the system.

Dual-cylinder Rotary Core Kiln

10+m³/h Processing Capacity

Unique dual-cylinder furnace structure enables multi-stage carbonization, which greatly improves operating efficiency of biochar pyrolysis machine.

- Inner cylinder performs intensive drying of the raw biomass to optimize moisture content.

- Outer cylinder carries out complete pyrolysis, maximizing carbon conversion efficiency and biochar yield.

BLL-30 Pyrolysis Plant is designed for large-scale waste processing with continuous operation and high efficiency. Its advanced features ensure stable performance, making it an ideal solution for high-capacity waste treatment & recycling projects.

Anti-polymerization Condensation

30 Days Continuous Operation

By oil-gas spray mixing condensation, the technology quickly lowers temperature and improves condensation efficiency. It prevents olefin compounds from secondary polymerization and clogging the pipes.

Hot Flue Gas Recirculation

↓ 55% Fuel Use & ↓ 50% Emission

80% flue gas is evenly mixed with hot air in combustion chamber to heat pyrolysis reactor. Meanwhile, 20% flue gas heats the burner combustion air. This improves thermal efficiency and alleviates emission impacts.

Automatic Temperature Control

80% Less Manual Work

This technology realizes automatic and precise temperature control of ±10℃. With continuous feeding and unloading, the equipment only requires two operators, which reduces manual intervention by 80%.

Fractional Distillation Technology

2 Types of Oil, 1 Step Collection

In condensation stage, naphtha with a boiling point below 200°C is sent to light oil tank. Non-standard diesel oil with a boiling point above 200°C is sent to heavy oil tank. Fractionation eliminates the need for distillation equipment while obtaining higher quality oil.

Large-Capacity Reactor

50%↑ Processing Capacity

The reactor of BLJ-20 pyrolysis plant is with dimensions of ø2800*10000. It offers a 50% increase in processing capacity compared to traditional batch main furnace. For example, the oil sludge treatment capacity increased from 16-18 t/batch to 20-22 t/batch.

Sealing & Insulation Upgrade

No Open Flame, No Oil Gas Leaks

BLJ-20 uses thermal dynamic sealing and flexible high-temperature insulation technology. There are no oil gas leaks or open flames at the operating site. This technology significantly improves operational safety and reduces the risk of thermal hazards.

Workflow of Pyrolysis Machine

Step 1: Raw Material Pre-treatment

Depending on the feeding method, various raw materials are processed to the appropriate size. Additionally, to ensure thermal efficiency, the raw materials must undergo dehydration or drying treatment before feeding.

Step 2: Pyrolysis

After entering the reactor, the raw materials are heated in an oxygen-deprived environment. Long-chain structures like polymers, petroleum hydrocarbons, and cellulose break down into gases. Unpyrolyzed material forms solid residues.

Step 3: Condensation

The small gaseous molecules enter the condensation system. The condensable portion forms liquid oil, which is stored in the oil tank. Note that biomass pyrolysis does not condense bio-oil, as it can clog the system and affect its operation.

Step 4: Gas Recovery

Non-condensable gases form syngas. After purification, they enter the combustion system for energy supply. In addition, high-temperature flue gases carrying a significant amount of heat are directed to various systems for waste heat recovery.

Step 5: Discharging

The solids generated from pyrolysis (carbon black, biochar, industrial residues) are discharged from the pyrolysis reactor. To lower their temperature, pyrolysis equipment will adopt multi-stage water-cooled screw extractors for collection.

Step 6: Exhaust Gas Treatment

Exhaust gas undergoes cooling, dust removal, desulfurization, and denitrification before discharge through the chimney. We can assist clients in customizing exhaust gas treatment systems based on local emission requirements.

High-value Application of End Products from Pyrolysis Plant

Biochar

Pyrolysis Oil

Carbon Black

Agriculture and Forestry

- Soil Improvement: Biochar improves soil aeration and water retention. It also helps increase soil organic matter.

- Seedling Substrate: Biochar enhances drainage and aeration in the substrate, promoting root development and preventing diseases.

Livestock

- Feed Additive: Adding biochar to feed improves animal gut health and nutrient absorption.

- Bedding Material: Biochar absorbs harmful gases and moisture, reducing odors and bacterial growth.

Construction

- Building Materials: As a lightweight aggregate additive, biochar improves structural strength.

- Road Materials: When added to asphalt, biochar improves compressive strength and extends road lifespan.

Metal Smelting

- Reducing Agent: Biochar, as a reducing agent, lowers energy consumption during the reduction process in smelting.

- Alternative Fuel: Biochar is used as an alternative energy source, reducing fossil CO2 emissions.

Pyrolysis Oil

- Chemical Raw Materials: It undergoes distillation and refining processes to obtain higher-quality oils.

- Industrial Fuel: It provides thermal energy in facilities with high energy demands, such as burners and boilers.

Non-standard Diesel

- Engine Fuel: Primarily used in heavy industrial equipment, such as mining machinery and agricultural machinery.

- Power Generation Fuel: Used as an alternative energy source in heavy oil power generation units.

Naphtha

- Petrochemical Raw Material: Used to produce basic chemicals like ethylene and propylene, which are applied in plastic processing.

- Gasoline Blending Agent: Used to improve the performance and combustion efficiency of gasoline.

Pyrolytic Carbon Black (PCB)

It is directly extracted through the pyrolysis process. Due to the presence of impurities, it has a lower quality. Therefore, it is mainly used in applications that do not require high performance:

- Rubber Reinforcement: Used in low-end rubber products to improve wear resistance and hardness.

- Building Materials: Used as a filler in materials like concrete and asphalt.

- Refinement: Further processing of raw pyrolytic carbon black improves its quality.

Recovered Carbon Black (rCB)

Recovered carbon black is a high-quality carbon black obtained by finely processing raw pyrolytic carbon black and removing impurities. It is therefore suitable for applications that require higher performance.

- High-Performance Tires: Used as a reinforcement agent in the tire industry to improve tire performance.

- Plastics and Coatings: Used as high-quality pigments and fillers to enhance color and durability.

- Conductive Materials: Used in conductive plastics and electronic devices, providing excellent electrical conductivity.

Pyrolysis Equipment Accelerates Sustainable Development Goals Achievement

SDG 7: Affordable and Clean Energy

Pyrolysis plant converts waste such as plastics, oil sludge, and tires into syngas and fuel oil. These energy sources can replace some traditional fossil energy. This reduces dependence on traditional coal, oil, and natural gas, thereby promoting energy structure transformation. These energy costs are lower and the selling price is reasonable.

SDG 12: Responsible Consumption and Production

The resource application of pyrolysis technology has significantly promoted the development of the circular economy. Because the waste is recycled and reused, it avoids direct incineration or landfill. Even by expanding the energy market and creating jobs, the development of pyrolysis plant for sale can drive the improvement of local economies.

SDG 13: Climate Action

Incineration and landfill are traditional waste treatment methods, which usually release a large amount of greenhouse gases and seriously affect climate change. Through pyrolysis technology, waste is converted into useful products instead of directly emitting pollutants, which significantly reduces greenhouse gas emissions.

SDG 14: Life Below Water

Oil mining waste and plastic waste pose a serious threat to the marine ecological environment. In particular, the spread of microplastics has become a global problem. Pyrolysis machine can process these industrial wastes on a large scale, preventing harmful substances from entering the marine ecosystem, thereby promoting underwater life protection.

Potential of Pyrolysis Plant for Sale in Global Markets

Policy-driven Market

Potential: High

Applicable Regions: Developed countries such as Europe and North America

Features:

- Policy Promotion: Policy-driven markets usually have strong environmental regulations, such as carbon emission restrictions and plastic bans. This promotes the application of green technology.

- Fiscal Incentives: The government provides fiscal incentives to support the promotion of environmental protection technologies. Pyrolysis unit can enjoy these policy supports.

Raw material-rich Market

Potential: High

Applicable Regions: Middle East and African countries

Features:

- Waste Accumulation: The waste management system in these regions is imperfect, and wastes such as plastics, tires, and oil sludge are piled up, and effective treatment solutions are urgently needed.

- Resource Recovery Demand: A large amount of waste is to be recycled, and pyrolysis machine can convert these wastes into valuable by-products.

Energy-short Market

Potential: High

Applicable Regions: Regions far away from the energy supply chain, island countries with energy shortages.

Features:

- High Costs: These regions are seriously short of energy, rely on traditional energy, and have large fluctuations in energy prices. Pyrolysis plant can alleviate this dilemma.

- High Demand: These regions have a strong demand for alternative energy. Pyrolysis technology can produce clean energy from waste and help alleviate energy shortages.

Considerations Before Setting up a Pyrolysis Plant

Local Market Research

When assessing the development potential of a pyrolysis plant setup in the local market, several aspects need to be considered:

- Analyze the stability of raw material supply. This includes assessing the type, quantity and sustainability of locally available waste.

- Investigate sales channels for pyrolysis products. This is to ensure there is sufficient market demand to support production of the project.

- Evaluate the project’s profitability cycle. This is to explore the feasibility of increasing the production scale of the pyrolysis projects in the future.

Safety and Environmental Impact Assessment

- Safety impact assessment involves assessing the impact a project may have on worker and public safety, such as fires, explosions and accidents.

- Environmental impact assessment includes an assessment of the impact a project may have on soil, water resources, air quality and ecosystems.

Beston pyrolysis plant can be flexibly configured according to the policy requirements of different regions. This ensures compliance and sustainability of the project. In addition, we provide a variety of documents support to assist customers in completing assessment.

Construction Planning

- Advance Civil Engineering: Before equipment installation, clients should complete the construction of roads, water supply, power supply, etc. in advance. Beston Group provides relevant drawings and technical support.

- EPC Construction: Beston Group provides comprehensive EPC (Engineering, Procurement, and Construction) services. Clients can rely on this integrated service solution for the delivery of the entire production facility.

Relevant Personnel Arrangement

- The installation of equipment requires workers of different types of work to work together. This includes unloading, assembly, welding, etc. Beston Group provides installation manuals and engineer on-site guidance. This allows the installation to proceed smoothly.

- Project operation team is equally crucial. Our installation engineers assist customers in training professional operations teams. We ensure that our customer’s teams have the necessary skills and knowledge to successfully implement and operate the entire project.

In the End

Beston pyrolysis plant turns waste into energy. At present, the nonrenewable resources have become more and more precious. These end products can yet be regarded as a great alternative to energy. Now, we offer batch, and continuous models to process various solid wastes. Based on good services, we offer flexible payment methods, turnkey projects, and a period of tracking service. If you want to get more information about Beston Group’s pyrolysis projects, please visit our LinkedIn.