The plastic to fuel machine utilizes cutting-edge technologies to convert waste plastics into valuable fuel. Beston Group provides both catalytic pyrolysis technology for cleaner oil output and continuous pyrolysis systems for stable, long-duration operation. Our solutions help customerss reduce environmental impact while improving processing efficiency worldwide. All in all, plastic into fuel machinee is ideal for sustainable waste management and commercial fuel production.

Why Turn Plastic into Fuel?

Energy Gap Expansion

Global energy security discussions increasingly highlight the vulnerability of existing energy supply chains, particularly under fossil fuel price volatility and an accelerated energy transition.

- Developing alternative fuel sources has become a strategic priority for governments and industrial sectors.

- Plastic-to-fuel technologies are emerging as a viable pathway to supplement conventional energy supply.

According to Grand View Research, the global plastic-to-fuel market is projected to grow at a compound annual growth rate of over 20% by 2033, expanding from approximately USD 920 million in 2025 to several billion dollars.

Recycling Policy Drive

As plastic recycling policies tighten worldwide, circular economy frameworks are becoming more robust.

- Many regions have set higher recycling rate targets and introduced energy recovery requirements.

- The EU Waste Directive mandates member states to improve plastic recycling performance and promote innovation across the waste-to-energy recovery chain.

- Fiscal incentives and regulatory frameworks are accelerating the development of chemical recycling to complement mechanical recycling.

This policy direction addresses the growing challenge of complex and mixed plastic waste streams.

Waste Management Challenges

Global plastic production continues to rise, while recycling rates lag far behind waste generation, creating mounting waste management pressures.

- In 2024, global plastic production is estimated to exceed 500 million tons.

- Approximately 399 million tons of plastic ultimately becomes waste.

- Less than 10% of plastic waste is recycled.

Existing landfill and incineration methods consume large land resources and may release harmful pollutants and greenhouse gases. Plastic-to-fuel technologies provide a resource recovery pathway by converting difficult-to-recycle plastic waste into valuable energy products.

3 Types of Plastic Derived Fuels

Liquid Fuel: Pyrolysis Oil

Pyrolysis technology heats waste plastic in an oxygen-limited environment. It breaks down the plastic into liquid fuel, gas, and industrial residue. Pyrolysis oil can be further refined into non-standard diesel, naphtha, and other fuels.

- High Energy Density: Pyrolysis oil has a high energy density, used in industrial transport, energy production, and other fields.

- Product Adjustability: Plastic pyrolysis oil can be further processed as needed to produce fuels of various specifications.

- Complex Operation: Pyrolysis technology requires high temperatures and precise control. Equipment and maintenance costs are relatively high.

Solid Fuel: Refuse-derived Fuel

RDF technology selects combustible components from municipal solid waste, such as waste plastics, paper, and wood. It then undergoes physical processing, such as crushing, drying, and pelletizing, converting them into solid fuel.

- Simple & efficient: The production process of RDF fuel is simple. It is suitable for large-scale mixed waste plastics.

- Wide Application: RDF can be directly used as fuel in industrial boilers, thermal power plants, and more.

- Pollution Issues: Releases a large amount of CO₂ (about 0.9-1.5 tons CO₂/ton of RDF), chlorides and nitrogen oxides.

Gaseous Fuel: Syngas

Gasification technology converts waste plastic into syngas in a high-temperature, low-oxygen, or no-oxygen environment. The produced gas mainly consists of hydrogen, carbon monoxide, and carbon dioxide.

- Energy Diversity: Syngas can be used for power generation, chemical synthesis, and more. It has a wide range of applications.

- High Adjustability: By adjusting gasification conditions, the composition and properties of the syngas can be controlled.

- High Industry barriers: Gasification equipment costs are high, and operation is complex. It is not suitable for small to medium-scale processing.

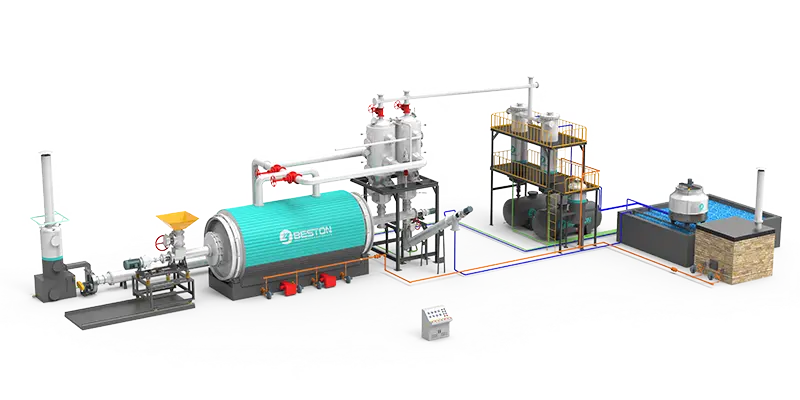

Plastic to Fuel Machine: 200% Efficiency with Catalysis System

Traditional plastic pyrolysis plant faces a technical obstacle – wax oil condensation causing pipe blockage. In Beston plastic to fuel machine, catalytic pyrolysis technology solves this problem. When pyrolysis oil gas passes through the catalytic tower, the catalyst quickly decomposes the wax molecules to prevent blockage. This catalytic action not only eliminates operational bottlenecks, but also increases the efficiency of the pyrolysis reaction by 200%. The adoption of this technology brings three core values:

ISCC-Grade Fuel Output

The catalytic upgrade allows plastic into fuel machine to produce cleaner, more refined oil that meets ISCC (International Sustainability and Carbon Certification) standards. This brings multiple downstream benefits:

- Access to premium markets: ISCC-grade oil is recognized in regulated fuel sectors across Europe and other regions, enabling higher-value sales.

- Support for sustainability claims: Certified output strengthens the end-user’s carbon reduction narrative and ESG reporting.

- Facilitates carbon credit participation: With verified traceability and sustainability, producers are eligible for carbon markets and subsidies.

Say Goodbye to Frequent Maintenance

Traditional systems often suffer from wax oil condensation, leading to clogged pipelines and forced downtime. The catalytic tower solves this by breaking down high-molecular compounds before they settle. The impact is immediate and long-term:

- Fewer shutdowns: Continuous operation becomes possible for longer stretches, improving throughput and cost-efficiency.

- Lower labor intensity: No need for frequent manual cleaning or mechanical disassembly, reducing operational workload.

- Equipment protection: Stable internal conditions prevent thermal stress, prolonging the lifespan of key components like reactors and condensers.

Choose the Right Model of Plastic to Fuel Machine for Sale

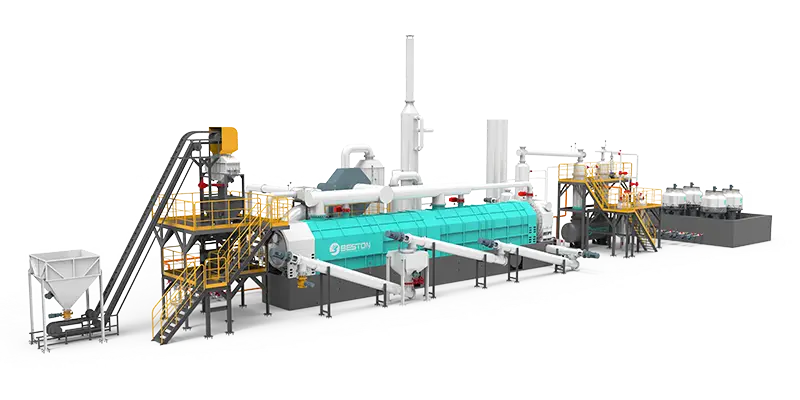

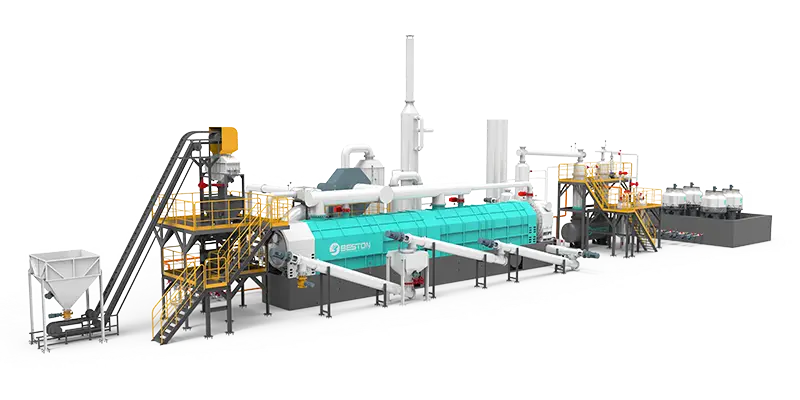

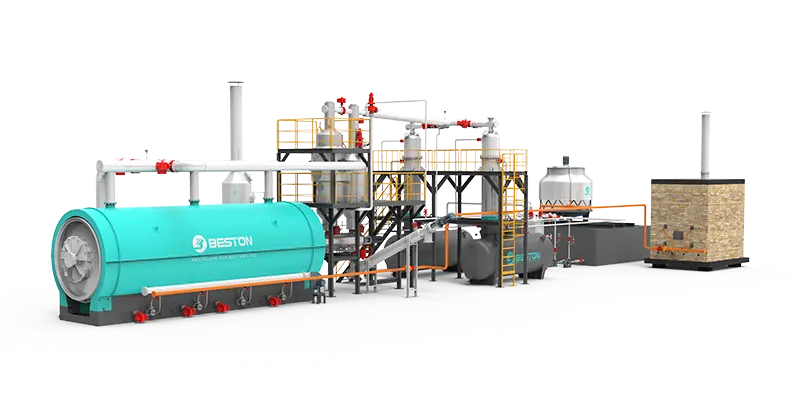

Continuous Type: BLL-30

- Process 6,000 tons waste plastic annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

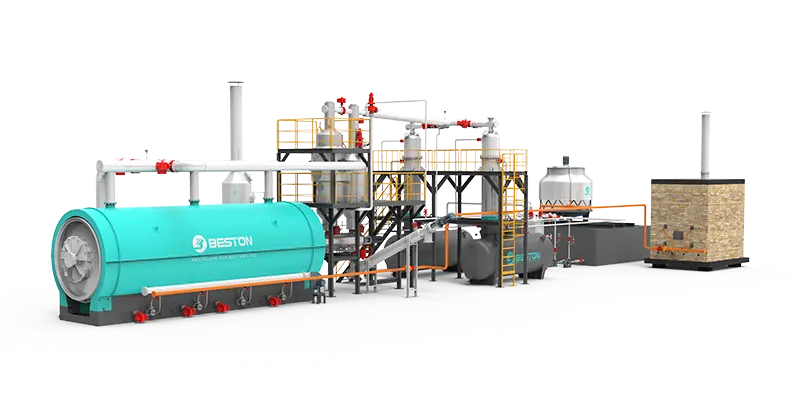

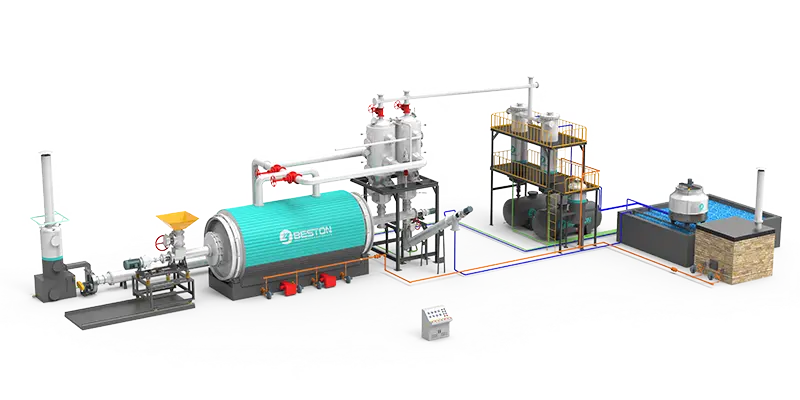

Batch Type: BLJ-20

- Process 4,000 tons waste plastic annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons waste plastic annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

Cutting-edge Innovation of BLJ-20 Plastic into Fuel Machine

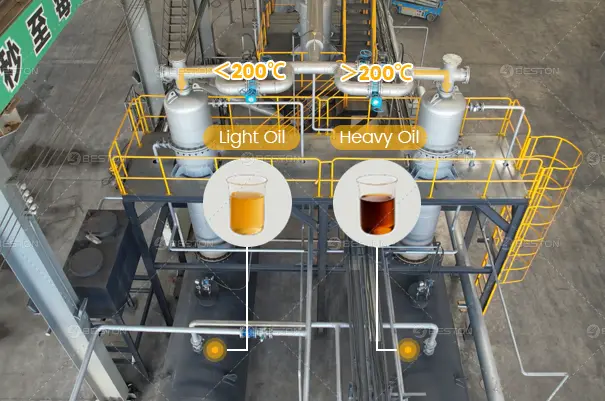

2 Oil Grades, 1-Step Separation

This technology separates pyrolysis oil gas by boiling point. Naphtha (<200 °C) to the light oil tank; non-standard diesel (>200 °C) to the heavy oil tank. The benefits include:

- Simplified Process Flow: Eliminates the need for downstream distillation equipment, reducing system complexity, footprint, and additional energy consumption.

- Higher Oil Value: Produces clearly graded oil products with improved consistency and usability, enhancing overall product quality and economic returns.

50%↑ Processing Capacity

Reactor dimensions of BLJ-20 plastic to oil machine are ø2800 × 10000 mm. This increases the batch processing capacity from 8-10 tons to 12-15 tons.

- Enhanced Operational Efficiency: Higher batch capacity reduces cycle frequency and handling operations, improving overall plant productivity.

- Lower Unit Processing Cost: Higher throughput spreads fixed costs across larger volumes, improving cost control and project-level returns.

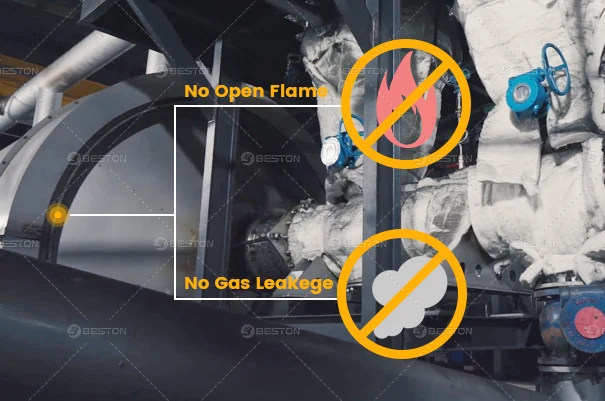

No Open Flame, No Oil Gas Leakage

BLJ-20 plastic to fuel machine integrates thermal dynamic sealing with high-temperature insulation to fully isolate pyrolysis gases, ensuring leak-free operation without open flames. It brings:

- Improved Operational Safety: Prevents oil-gas leakage and uncontrolled ignition, significantly reducing fire and explosion risks during operation.

- Lower Thermal Risk Exposure: Stable insulation performance minimizes heat loss and thermal hazards, supporting safer, more reliable long-term plant operation.

Technological Breakthrough of BLL-30 Continuous Plastic into Fuel Machine

Anti-Polymerization Condensation Technology

This system uses oil-gas spray mixing to quickly reduce the temperature of oil vapor. It increases condensation efficiency and prevents olefins from polymerizing in pipelines. As a result, the plastic to fuel machine can run continuously for 30 days without shutdown.

It is a critical upgrade for any plastic to fuel machine aiming for stable, long-term performance.

- Stable operation: Continuous 30-day runtime with no need for shutdown or cleaning.

- Lower maintenance costs: Prevents clogging and reduces the need for pipe cleaning and part replacement.

- Extended equipment lifespan: Clean pipelines reduce system wear and tear.

Hot Flue Gas Recycling & Air Preheating

A high-temperature stainless steel fan draws 80% of furnace flue gas back to the combustion chamber. It mixes with 1000–1300°C hot air from the burner and heats the reactor.

The remaining 20% of flue gas preheats fresh combustion air through a heat recovery unit. These two steps cut energy use by 55% and reduce exhaust emissions by 50%.

- Fuel savings: Up to 55% less fuel consumption, lowering operational costs.

- Environmental compliance: 50% fewer emissions make the system easier to meet EU standards.

- High thermal efficiency: Maximized heat utilization improves pyrolysis speed and stability.

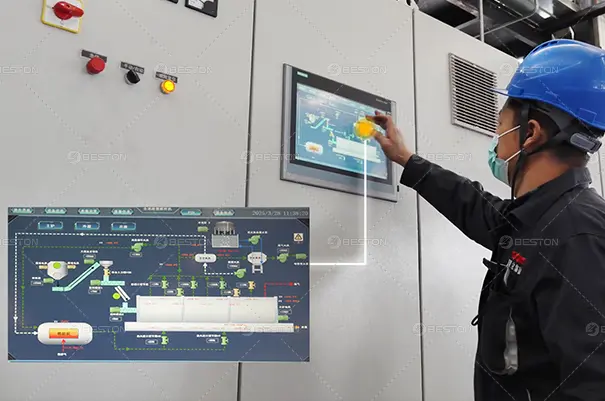

Automatic Furnace Temperature Control

The furnace uses a multi-media combustion valve set combined with hot air recycling to automatically adjust to different fuels. It controls temperature with ±10°C accuracy under varying conditions. This function ensures precise thermal regulation for continuous pyrolysis plant operating under fluctuating feedstock quality.

- Precise control: Accurate to ±10°C, ensuring stable operating conditions and consistent product quality.

- High automation: One-touch operation without frequent manual adjustments.

- Labor savings: Only 2 operators are needed, reducing reliance on skilled labor.

Application Scenarios of Plastic Fuel Oil

Oil from platic to oil machine can be refined into non-standard diesel and naphtha. This three kinds of oil product can offer various applications across industries.

Industrial Energy Supply

- Pyrolysis oil: Serve as fuel in industrial boilers, kilns, and furnaces.

- Non-standard diesel: Serve as fuel for powering heavy fuel oil generators.

Heavy Industrial Machinery

- Non-standard diesel: Fuels heavy-duty engines in trucks and machinery.

- Naphtha: Used as a blending component in gasoline production.

Chemical Raw Materials

- Naphtha: Feedstock for ethylene cracking in petrochemical production.

- Refined naphtha: Used as an industrial solvent in various chemical processes.

How to Convert Waste Plastic to Fuel?

In this pyrolysis process, the waste plastics are converted into fuel. Here are the steps involved in converting plastic to fuel:

Sorting and Pre-treatment

The first step is to sort the plastic waste by type and remove any non-plastic materials.

The plastic is then shredded into small pieces to facilitate pyrolysis.

Heating

Shredded plastics are fed into a plastic to fuel reactor in the absence of oxygen.

The temperature is between 280 to 800°C in the reaction.

This stage forms high-temperature oil gas.

Pyrolysis Oil & Syngas Formation

- Pyrolysis Oil: High-temperature oil and gas enter the manifold and catalytic tower to separate heavy oil substances and wax oil impurities.

The purified oil and gas enter the condenser, where they are condensed to form plastic pyrolysis oil. - Syngas: The flue condenser and water seal purify the non-condensable oil gas to form syngas, which provides heat source for the pyrolysis reaction again.

Emission Gas Treatment

The emission gases can be treated to remove pollutants by a de-dusting system before being released into the atmosphere.

The dedusting system includes condenser and atomization tower.

Beston Group provides customized de-dusting system to meet the emission requirement in the local area.

Send your demand to Beston Group.

Solid Discharging

After the volatile hydrocarbons in the plastic are completely involved in the pyrolysis reaction, solid residues are left, which are discharged through a water-cooled discharger.

The Plastic Oil Rate in the Pyrolysis Process

The plastic oil rate varies depending on several factors, including the type of plastic waste being processed, the quality of the waste plastic to fuel conversion plant, and the operating conditions of the machine. Generally, the plastic oil rate ranges from 20% to 90% of the total weight of the plastic waste.

The type of plastic waste being processed can have a significant impact on the plastic oil rate. Some types of plastic, such as polyethylene and polypropylene, have a higher plastic oil rate than others, such as PP and PE. This is because the molecular structure of these plastics is more conducive to the pyrolysis process.

Beston Plastic to Fuel Machine Project over the World

Beston Group is a well-known plastic to fuel machine manufacturer and has shipped its products to over 80 countries worldwide. We has built a strong reputation for producing high-quality machines that are reliable, efficient, and environmentally friendly. Beston plastic to fuel oil machines are the go-to choice for many customers because of several reasons, including their innovative technology, outstanding customer service, and competitive pyrolysis plant prices. Please see the detailed cases.

Get Your Plastic to Fuel Solution

Plastic to fuel machine is redefining how plastic waste is handled in industrial systems. Instead of treating discarded plastics as a disposal burden, this technology enables their conversion into fuel outputs that can re-enter the energy chain. As industries face mounting pressure from sustainability targets and cost control, plastic to fuel solutions are being adopted as a practical operational tool rather than a conceptual alternative. Their value lies in bridging waste management, energy recovery, and circular economy objectives. For ongoing updates on plastic recycling and waste-to-fuel innovation, follow us on LinkedIn.