Continuous pyrolysis plant provides a solution for the large-scale recycling of solid waste. Common types of recyclable waste include oil sludge, discarded plastics, and end-of-life tyres. Their common features are difficulty in reduction and resource utilization. However, continuous pyrolysis technology can solve the above problems. In the pyrolysis reaction, the organic volatile components in the solid waste form pyrolysis oil, carbon black, and syngas. They are high-value products with a wide range of uses.

Future of Pyrolysis: Global Transition to Continuous Operation

Waste Management Challenge

Increased Compliance Difficulty

Progressive Automation Technology

Low-Risk Investment Requirement

Petroleum-derived wastes create huge recycling challenges:

- Plastic Waste: The world produces 400 million tons of plastic every year. Most of it is still not recycled.

- Scrap Tires: Industries discard more than 1 billion tires annually. Conventional recycling methods cannot keep up.

- Oil Sludge: Crude oil production generates about 60 million tons of sludge each year. This waste is hazardous and costly to treat.

These waste streams keep growing. Therefore, only a industrial-scale continuous pyrolysis plant with no intermittent operation can complete such a huge task of reduction & resource utilization.

Environmental regulations are becoming stricter worldwide. Continuous pyrolysis plant meets these requirements more effectively than batch systems.

- Tighter Limits: The European Union’s Industrial Emissions Directive 2.0 came into effect on August 4, 2024. It sets stricter emission limits and expands supervision.

- Batch Limitations: Small pyrolysis machine struggle to control emissions consistently. This means that carrying out projects in compliance review areas will be challenging.

Stricter regulations push the industry toward continuous operation, ensuring compliance while maintaining efficiency.

Industries are adopting intelligent control solutions to improve operations. Automation enhances process stability and efficiency.

- Real-Time Monitoring: IoT and PLC systems track temperature, pressure, and gas composition continuously.

- Stable Operation: Closed-loop control keeps production steady and reduces energy waste.

- Efficiency Boost: Automation optimizes resource use and ensures consistent output.

Advanced continuous plant enables smarter, more efficient industrial processes and supports modern operational trends.

High efficiency and low operating costs make continuous pyrolysis plant attractive for investors. Returns can be realized relatively quickly.

- Energy Savings: By-products such as syngas can be reused to reduce fuel costs.

- Financial Incentives: Tax exemptions, subsidies, and carbon credits shorten payback periods.

- Rapid ROI: Investors can typically recover their principal within 1–3 years.

These factors make pyrolysis projects a practical, low-risk investment with long-term benefits.

Basic Information of BLL-30 Continuous Pyrolysis Plant

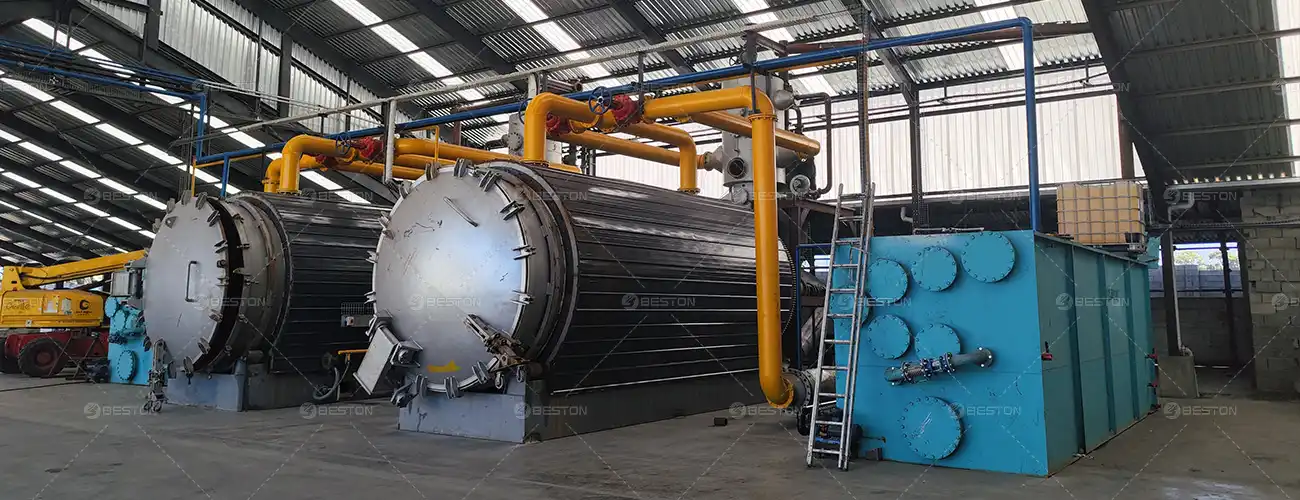

After unremitting technological innovation, Beston Group officially launched the self-developed BLL-30 continuous pyrolysis plant. The entire system adopts high-quality materials and sophisticated design. Therefore, this model has become a good choice for recyclers to carry out large-scale industrial projects. Below provides you with a detailed main component and parameter table for your reference.

| Model | BLL-30 |

| Manufacturer | BESTON |

| Time to Market | 2025 |

| Motor Brand | Chinese brand |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h |

| Working Method | Fully Continuous |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Materil | 304/310S Stainless steel |

| Reactor Life Span (Years) | 5-8 |

| Guarantee (Months) | 12 |

| Delivery Time (Calendar Days) | 60-90 |

| Land Space Required (L*W*H*m) | 70*20*10 |

| Packing | 20*6*3m in bulk+13*40HQ |

| Installation Period (Calendar Days) | 90 |

| Packing | 20*6*3m in bulk+13*40HQ |

| Installation Period (Calendar Days) | 60-90 |

3 Technological Breakthroughs of BLL-30 Continuous Pyrolysis Plant

BLL-30 continuous pyrolysis plant is engineered for large-scale waste processing. Its high efficiency and stable operation make it ideal for high-capacity recycling projects. The system incorporates three key technological breakthroughs:

Anti-polymerization Condensation

30 Days Continuous Operation

By oil-gas spray mixing condensation, the technology quickly lowers temperature and improves condensation efficiency. It prevents olefin compounds from secondary polymerization and clogging the pipes.

Hot Flue Gas Recirculation

↓ 55% Fuel Use & ↓ 50% Emission

80% flue gas is evenly mixed with hot air in combustion chamber to heat pyrolysis reactor. Meanwhile, 20% flue gas heats the burner combustion air. This improves thermal efficiency and alleviates emission impacts.

Automatic Temperature Control

80% Less Manual Work

This technology realizes automatic and precise temperature control of ±10℃. With continuous feeding and unloading, the equipment only requires two operators, which reduces manual intervention by 80%.

3D Visualization of Key Innovations of BLL-30 Continuous Pyrolysis Plant

Raw Materials for Continuous Pyrolysis Machine

Waste Plastic

Plastic is composed of high molecular polymers. Its main component is petroleum derivatives. The main sources of waste plastic are as follows:

- domestic waste landfill

- plastic product manufacturer

- renewable resources recycling

Oil Sludge

Oil sludge is a mixture consisting primarily of petroleum product residues, soil, water, and other impurities. Its main sources are as follows:

- oilfield drilling and production

- crude oil gathering and transportation

- refinery wastewater treatment

Waste Tyre

Tyres are composites made of rubber, steel wire, fiber, and other materials. The sources of waste tyres are quite wide, mainly as follows:

- end-of-life tyre recycling center

- transportation & industrial vehicles

- tyre manufacturer

Working Process of Continuous Pyrolysis Plant

01 Raw Material Pretreatment

02 Raw Material Feeding

- Large-inclination Belt: mainly targeted at solid granular such as tyre rubber powder, plastics particles, and oil sludge with a liquid content of less than 40%.

- Shaftless Screw: oil sludge with a liquid content of 40%-60%.

- Oil Slurry Pump: oil sludge with a liquid content of more than 75%.

03 Pyrolysis

04 Oil Gas Condensation

05 Syngas Recovery

06 Exhaust Gas Treatment

07 Solid Residue Discharging

Extensive Application Scenarios for Continuous Pyrolysis Products

The main products from continuous pyrolysis equipment contain pyrolysis oil, carbon black, syngas, and steel wire(from continuous tyre pyrolysis plant only). These sustainable materials have a wide range of applications across various industries. Therefore, these pyrolysis products have considerable economic value. Here are some common application scenarios:

| Product | Raw Material | Application |

|---|---|---|

| Pyrolysis Oil | Plastic / Oil Sludge / Tyre | Used as heavy industrial fuel; Feeds heavy oil generators after distillation; Produces gasoline and diesel after refining; |

| Wax Oil | Plastic | Used as heavy industrial fuel; Fuels marine vessels; Produces gasoline and diesel after refining; |

| Naphtha | Plastic | Produces ethylene, propylene, and other basic chemicals; Acts as a solvent for paints, coatings, and industrial use; Blends into gasoline formulations; |

| Solid Residue | Plastic / Oil Sludge | Forms construction materials; Manufactures permeable bricks; |

| Carbon Black | Tyre | Fills general rubber products; Additive for coatings and inks; Processes further into N660, N550, or rCB; |

| Steel Wire | Tyre | Recycles into new steel products; |

Innovative Technologies in Continuous Pyrolysis Machine

Beston Group has many years of experience in equipment design, manufacturing, installation, and operation. Therefore, we have developed mature continuous pyrolysis technology. Many advanced structures and patented technologies are used in this model. And many key performance parameters are excellent. The following gives you a detailed introduction to innovative technology used in the equipment.

Anti-Coking Technology

- Uniform Hot Air Heating: The main furnace uses hot air to heat the reactor evenly, preventing local overheating and material coking.

- Mechanical Anti-Coking: The furnace has a mechanical device that removes coke from the reactor wall, improving efficiency.

Sealing Technology

- Dynamic Furnace Sealing: High-temperature flexible dynamic sealing keeps the reactor sealed during continuous feeding and gas discharge, ensuring safe operation.

- Discharge System Sealing: Water-cooled discharge box with level sensors and material locks prevents high-temperature oil and gas leakage, avoiding air ingress.

Feeding Technology

- Precise Feeding: Dual screw conveyors and weighing system control feed volume accurately, and maintain airtightness at the feeding inlet.

- Inert Gas Protection: Nitrogen with over 95% purity replaces air in the feed bin, maintaining a low-oxygen environment for safe pyrolysis.

Intelligent Control Technology

- PLC Central Control: Central management of start/stop, temperature, and pressure ensures unified and standardized operation.

- Remote Monitoring: IoT technology allows real-time monitoring and timely adjustments, maintaining stability and safety of the system.

Profitable Pathways for Continuous Pyrolysis Plant

Pyrolysis Product Sales

Relying on the advancement of production technology of continuous pyrolysis machine, the market prospects for pyrolysis products are optimistic:

- Pyrolysis Oil: With the transformation of traditional energy structure, sustainable energy has gradually become the choice of some enterprises. As an alternative fuel, it is competitive in the fuel market.

- Carbon Black: It is widely used in industries such as tires, plastics, and coatings. The market demand for carbon black is stable, especially in emerging markets with strong growth potential.

Value-added of Industrial Chain

The extension of the industrial chain can not only enhance the market value of products, but also help enterprises form differentiated advantages:

- Pyrolysis Oil: It can produce high value-added non-standard diesel, naphtha, wax oil, etc. through processes such as distillation. Its market application range and commercial value are greater than the initial pyrolysis oil.

- Carbon Black: As an important by-product of pyrolysis products, it can be processed to prepare higher precision carbon black, even rCB through deep processing. It is widely sold to industrial manufacturing, especially recovered tyre.

Disposal Fee Revenue

- In the process of disposing of plastics, oil sludge, and waste tires, environmental protection policies in many regions require them to be harmlessly treated. Many industrial enterprises and government departments often need to pay certain disposal fees when using continuous pyrolysis plant to treat these wastes.

- As the policy of waste recycling and reuse is gradually strengthened, pyrolysis plants can establish long-term cooperative relationships with local governments or related enterprises. This can obtain more disposal contracts, thereby increasing a stable source of income.

Policy-specific Subsidy

- In some regions, pyrolysis projects can obtain special funding support from the government for sustainable projects. These subsidies can not only reduce the initial investment of the project, but also provide financial guarantees for the cost of the pyrolysis plant to help enterprises.

- In addition, some regions have also introduced a series of policies such as tax incentives and land use incentives. Therefore, policy subsidies provide strong financial support for pyrolysis projects, which helps them gain long-term competitive advantages in the market.

Pyrolysis Projects of Beston Group Worldwide

As a solid waste recycling expert, Beston Group has been committed to providing customers with integrated solutions. Meanwhile, we actively establish cooperation with customers around the world to jointly solve challenges in solid waste recycling. The long-term success of customers’ projects has always been the goal of Beston Group. Below are some successful cases of pyrolysis projects. If you want to know more about Beston Group, please follow us on LinkedIn.

Work with Beston Group

As the concept of sustainable recycling takes hold, continuous pyrolysis plant is seen as the future of solid waste recycling. We believe that cooperating with Beston Group on pyrolysis project will be an important step in promoting resource recycling. As a reliable manufacturer and professional solution provider, Beston Group provides customers with high-quality equipment and services. If you want to start a solid waste recycling business plan, don’t hesitate to join us.