Wood charcoal making machine is taking the world by storm as an innovative solution for waste wood management. The machine uses pyrolysis technology to convert wood into charcoal. Whether it is forest management residues or wood processing waste, this machine enables efficient recycle. Beston Group’s wood charcoal machine is known for flexible configuration options and reliable quality. More and more customers are choosing us as a provider of wood recycling solutions.

BST-50S Wood Charcoal Making Machine: Puro.earth Vetted Model

operation time annually

biochar production

emissions meet standards

🔥 2 Core Technologies Support Technical Evaluation

Tar & Wood Vinegar Self-Cleaning System

Multiple insulation facilities and purge units are set up in the wood charcoal machine. This prevents the tar wood vinegar released from the system from adhering to the charcoal powder in the pipeline. This brings the following advantages:

- Ensure the equipment operates safely and stably for 7,200 hours a year.

- Avoid production losses caused by frequent downtime due to system blockage and failure.

- Avoid additional maintenance costs, including parts, labor, etc.

Dual-cylinder Rotary Core Kiln

The biomass raw materials first enter the inner cylinder for thorough drying. Under the action of the guide plate, the materials enter the outer cylinder for deep carbonization. The structure brings wood charcoal making machinethe following advantages:

- Graded design enables the pyrolysis plant to process over 10 m³ of material per hour.

- Thermal utilization rate is more than doubled compared to single-layer external heating structure

- While ensuring the full reaction time, the total length of the main furnace is reduced

2 Models Wood Charcoal Making Machine for Sale

Commercial Scale: BST-50

- 6,000 tons charcoal production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

- BST-50S technology vetted by puro.earth

Testing Scale: BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon sink process verification

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Real-World Success Cases: Wood Charcoal Making Machine in Asia

01 Problems & Challenges

A wood processing company in East Asia faced challenges related to the disposal of large volumes of wood waste. With no effective recycling way, the company incurred high disposal costs. Additionally, the customer aimed to enter the carbon removal credit market but lacked technical experience.

02 Change in Goals

The company set out to build a large-scale biomass waste processing line that could turn wood residues into valuable products. In addition to reducing waste, their long-term goal was to participate in the voluntary carbon market by producing biochar that meets carbon removal certification standards.

03 Action Solution

Beston Group provided a complete solution centered around the BST-50 wood biochar machine. We also supported the client with project documentation and carbon accounting guidelines in preparation for future carbon credit trading.

04 Results Achieved

Wood to charcoal machine is running smoothly at the customer’s site. It has significantly reduced the wood waste volume while producing high-quality biochar. The client is now undergoing third-party auditing for biochar-based carbon removal certification.

Raw Material for Wood Charcoal Machine

Forest Management Waste

Byproducts from forest management, including branches, tree tops, stumps and roots, etc. The characteristics are as follows:

- Raw materials are scattered, high transportation cost;

- The moisture content is high;

- Carbon source of forest fire risk.

Sawmill Logging Waste

By-products from sawmills and primary processing, typical materials include: sawdust, wood chips, offcuts. Features are as follows:

- Small particle size, high dryness.

- Concentrated production, easy to store and transport

- Usually used as fuel

Wood Product Processing Waste

From wood product manufacturing. Typical raw materials include furniture offcuts and construction timber waste. Features:

- Large size difference;

- Raw materials contain impurities;

- Requires pre-processing, such as crushing and nail removal.

Use of Wood Charcoal in Multiple Industries

Agriculture

Animal Husbandry

Construction

Heavy Industry

Wood charcoal is widely used in agriculture due to its porous structure, high carbon content, and soil-enhancing properties. It improves soil health while sequestering carbon for long-term climate benefits.

- Soil Amendment: Improves soil structure, enhances nutrient retention and microbial activity, and increases water-holding capacity.

- Cultivation Substrate: Used in seedling nurseries and greenhouse crops as a porous, aerated growing medium when mixed with compost or peat.

In livestock farming, wood charcoal is valued for its detoxifying, odor-control, and moisture-regulating properties. It enhances animal health and hygiene without introducing harmful chemicals.

- Feed Additive: Added to animal feed to absorb toxins, improve digestion, and support gut health in livestock.

- Bedding Additive: Mixed into animal bedding to control odors, reduce ammonia, and improve hygiene in barns and stables.

As the construction industry seeks sustainable alternatives, wood charcoal has emerged as a low-carbon additive that improves building material performance while reducing environmental impact.

- Building Materials: Incorporated into concrete, bricks, or cement mortar to enhance insulation, humidity control, and reduce carbon footprint.

- Pavement Materials: Added to asphalt mixtures to improve durability, water retention, and environmental sustainability of roads.

Wood charcoal serves as a cleaner, renewable substitute for fossil fuels and coke in heavy industry, offering both environmental benefits and functional performance in high-temperature processes.

- Fuel for Energy Production: Serves as a renewable fuel in industrial kilns and bio-energy boilers, replacing fossil coal.

- Metallurgical Reductant: Used in smelting as a reducing agent, especially in low-carbon steel and alloy production.

Application Scenarios of Wood Charcoal Making Machine

Forest Residue Management

Wood Processing Waste Recycling

Reduce Natural Resource Use

Traditional charcoal production often relies on natural log resources. Modern biomass pyrolysis machine offer a sustainable alternative by:

- Utilizing forestry residues such as dead branches, tree crowns, and stumps as the main raw materials;

- Improving charcoal yield and quality per unit of raw material through efficient processing;

- Fundamentally reducing dependence on natural forest resources.

Avoid Wildfire Risk

Leaving flammable waste wood on forest land increases wildfire risks, especially during the dry season. Wood charcoal machine offers a dual benefit:

- Proactively removes combustible materials to prevent large-scale forest fires;

- Converts waste into valuable biochar, promoting safe and sustainable forest management.

Improve Soil Environment

Biochar application in forest soil brings both agronomic and ecological benefits:

- Enhances soil nutrient availability and water retention;

- Promotes root growth and improves plant nutrient uptake;

- Increases soil organic matter, improves soil structure, and boosts microbial activity;

- Accelerates forest regeneration and carbon absorption capacity.

Generate Additional Income

Using wood charcoal making machine to produce charcoal turns a disposal problem into a profit opportunity.

- Abundant raw material: Wood industries generate large volumes of sawdust, wood chips, and offcuts during processing.

- High-value conversion: These by-products can be converted into marketable charcoal through pyrolysis instead of being discarded.

- Economic return: Selling the resulting charcoal provides a new revenue stream and improves overall plant profitability.

Supply Alternative Fuels

Charcoal made from wood waste serves as a clean and renewable fuel, helping wood factories reduce energy costs and fossil fuel dependence.

- Efficient energy source: Wood charcoal has high calorific value and can power kilns, dryers, and production equipment.

- Fossil fuel replacement: Using charcoal lowers dependence on non-renewable energy sources like coal or gas.

- Cost-saving potential: In-house charcoal production can reduce energy expenses over time.

Offset Carbon Emissions

Wood to charcoal machine helps wood processing businesses reduce their carbon footprint by stabilizing carbon that would otherwise return to the atmosphere.

- Emission prevention: Waste wood releases CO₂ and methane when left to rot or burn openly.

- Carbon sequestration: Pyrolysis converts biomass into stable biochar, locking carbon in solid form for hundreds of years.

- Climate impact mitigation: Applying biochar to soil turns wood waste into a long-term carbon sink aligned with global decarbonization goals.

Working Process of Wood to Charcoal Machine

Wood Pretreatment

- Drying and Crushing: Wood materials are dried to less than 15% moisture and crushed to under 20mm (ideally 8–12mm) for optimal feeding.

- Dust Separation: If materials contain high dust content, a drum screen is recommended to remove fine particles before processing.

Wood Pyrolysis

- Feeding: Preprocessed wood is transported via a large-angle belt conveyor into a preheated biochar pyrolysis reactor.

- Thermal Reaction: Under a high-temperature, low-oxygen environment (380°C–450°C), moisture and organic volatiles are removed, forming carbon-rich charcoal.

Combustible Gas Recycling

- Gas Generation: Wood charcoal making machine generates H₂, CH₄, and CO, forming a combustible gas mixture.

- Gas Utilization: After purification through flue condensation and water sealing, the gas is reused as fuel for the furnace. Excess gas is collected or directed to the exhaust chamber.

Charcoal Collection

- Cooling & Discharge: Hot charcoal from the reactor is cooled in a water-cooled screw conveyor until its temperature drops below 45°C.

- Storage: Once cooled, the charcoal is safely collected and stored for further use or sale.

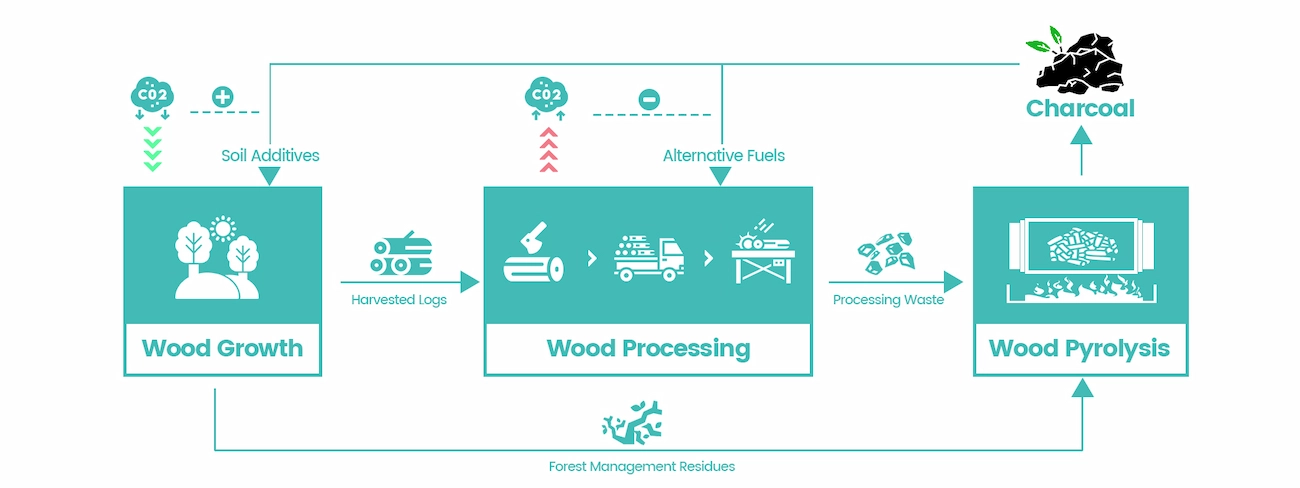

Wood to Charcoal Carbon Footprint Analysis

The use of a wood charcoal making machine enables a carbon-efficient cycle that turns wood waste into a long-term carbon sink while reducing emissions across multiple stages of the wood lifecycle:

01 Wood Growth

Carbon Footprint: Net carbon absorption from the atmosphere.

Carbon Status: CO₂ is stored as organic carbon in raw wood and forest waste.

02 Wood Processing

Carbon Footprint: CO₂ emissions from energy use during harvesting and processing.

Carbon Status: Carbon is retained in wood products and processing waste.

03 Wood Pyrolysis

Carbon Footprint: Small process emissions from pyrolysis, mostly biogenic.

Carbon Status: Carbon is sequestered as solid biochar, forming a long-term carbon sink.

04 Charcoal Utilization

Carbon Footprint: Avoided emissions from fossil fuel substitution; enhanced carbon uptake.

Carbon Status: Carbon remains stable in soil or cycles through biomass regrowth.

Advantages of Beston Wood Charcoal Making Machine

Continuous Operation without Stop

Beston wood charcoal machine can work without stopping for 24 hours continuously. And the automatic working method is able to guarantee a long-term working time and few larbor cost. This wood charcoal production method maximizes customers’ interests.

Guarantee the Safety to the Most Extent

Firstly, PLC is assembled with an alarm device. When some parts go broken, this part will alarm automatically. Secondly, there is an explosion-proof water seal at the end of the combustible gas flue. Thirdly, there is an explosion-proof hole at the end of the reactor to relieve extra pressure.

Save Your Fuel Cost Largely

After a period of preheating, the combustible gas processed by condensers is enough to provide heat for biochar reactor. And some part of high-temperature smoke has been applied to provide heat for the dryer. Accordingly, you can save a great deal of fuel cost when you choose Beston machines.

Make Sure Pollution-free Design

The environmental problem has become a serious matter we should pay attention to, especially in Asia and Africa. The government hopes more environmental protection industries will be introduced. Beston machine is the ideal equipment which has a dedusting system to clean the waste smoke.

Footprint of Beston Wood Charcoal Machine Spans Worldwide

Beston wood charcoal making machine is favored by recyclers worldwide. In completed projects, the machine has not only assisted customers in solving accumulation of waste wood but also generated impressive economic returns. Additionally, some customers have invested in wood pyrolysis projects to explore the emerging carbon offset industry. Here are some remarkable project stories for your reference.

Explore More with Beston Group

Wood charcoal making machine is more than just a waste-to-resource solution. It’s a strategic tool for reducing carbon emissions, enhancing resource efficiency, and unlocking new business value. From forest residues to sawmill waste, Beston Group provides tailored systems that align with sustainability goals across agriculture, forestry, and manufacturing industries. With increasing global demand for carbon removal technologies and renewable energy alternatives, now is the time to invest in scalable, proven solutions. Stay informed about our latest technologies, industry insights, and customer success stories on LinkedIn.