Rice hull carbonizer provides a sustainable solution for agricultural waste biomass recycling. The reduction & resource utilization of rice husk is always a difficult problem in the rice industry. Currently, making carbonized rice husk has become a mainstream method. By converting large quantities of rice husks into biochar, this solution increases the commercial value of this agricultural residue. At the same time, the eco-friendly machine design enables clean recycling. Therefore, rice husk carbonizer not only brings stable income to rice industry. In addition, The machine also lays the foundation for its sustainable development.

Current Status of Rice Husk Recycling

According to the Food and Agriculture Organization (FAO), global rice production is about 750 million tons per year. For every ton of rice, 0.2 tons of rice husk are produced. This means the global annual output of rice husk is around 150 million tons. However, less than 25% of rice husk is recycled. As a result, large amounts of rice husk are piled up, landfilled, or burned, leading to resource wastage and environmental pollution. Even with recycling methods, technical and market challenges remain.

Immature Technology

Current recycling technologies are inefficient. Some recycled products’ quality is unstable. For example, rice husk ash production is difficult to control due to fluctuating combustion conditions, leading to inconsistent product composition and properties. Additionally, the process consumes large energy, further raising costs.

Low Market Demand

Market demand for direct application of rice husk is limited. Using rice husk directly often requires additional processing, making recycling costs higher than its value. Furthermore, the effectiveness of rice husk is not as competitive as other alternative materials. It leads to less market demand for recycled rice husk.

Non-integrated Industry Chain

Rice cultivation and processing lack effective coordination. Growers focus on rice production, while processing plants concentrate on processing. In the current recycling system, there is no effective method or incentive to link the two, resulting in a lack of motivation within the entire industry chain to promote resource recycling.

Why Choose Rice Hull Carbonizer?

Reduction

- Significant Reduction in Waste Volume

Through cutting-edge rice husk charcoal making machine, the volume of rice husk is greatly reduced. Each ton of rice husk processed can reduce more than 50% of the waste volume, significantly alleviating waste accumulation and processing pressure. - High Consistency in Product Quality

Biochar from rice husk carbonizer has stable properties. Indicators such as hydrogen-carbon molar ratio, PAHs, and ash content are strictly controlled to ensure consistency and reliability of the product in various applications.

Resource Utilization

- Green Materials Market

An increasing number of industries require rice hull biochar, including agriculture, carbon removal, and energy production. As market demand grows, it has become a preferred solution for the green transformation of multiple industries. - CDR Market

The value of biochar in the Carbon Dioxide Removal (CDR) market is growing, with carbon prices rising steadily. As a durable carbon removal medium, rice husk biochar has become a sought-after resource in the carbon-neutral economy.

Specific Parameter of Beston Rice Husk Charcoal Making Machine

Commercial Scale: BST-50

- 6,000 tons charcoal production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

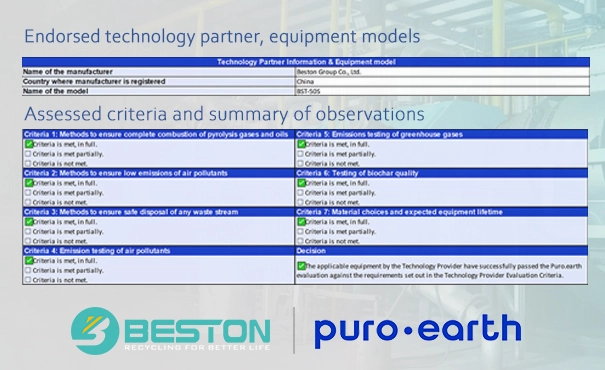

- BST-50S technology vetted by puro.earth

Testing Scale: BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon sink process verification

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

3 Guarantees Provided by BST-50S Rice Hull Carbonizer

Biochar Output Guarantee

BST-50S rice husk carbonizer uses dual-cylinder rotary core kiln technology to ensure efficient processing of raw materials and consistent production of up to 6,000 tons of biochar annually.

- Stable Supply: By producing a stable, high-quality output, BST-50S helps customers meet the growing demand for biochar in various sectors, supporting green transformation and sustainability efforts.

- Scalability & Profitability: The reliable production of 6,000 tons per year enhances business scalability and profitability, especially for industries focused on carbon sequestration and environmental remediation.

Continuous Production Guarantee

The tar and dust self-cleaning system ensures smooth operation of BST-50S biochar machine. It prevents blockages and allowing continuous production for 7,200 hours per year.

- Operational Efficiency: The ability to run continuously for 7,200 hours annually significantly reduces the risks of production interruptions, optimizing output and ensuring more consistent delivery to the market.

- Cost Reduction: It also reduces maintenance-related expenses, increasing the overall cost-effectiveness and enhancing the long-term sustainability of production.

Carbon Removal Technology Guarantee

BST-50S has passed the seven criteria technical assessment from puro.earth, ensuring compliance with international standards for carbon removal.

- Global Standards Compliance: By meeting rigorous international standards, BST-50S helps customers unlock opportunities in the rapidly growing carbon removal market.

- Additional Revenue Stream: The ability to earn carbon credits not only adds an additional revenue stream but also strengthens the customer’s position in the global push towards carbon neutrality, enhancing brand value and long-term profitability.

Successful Case: Rice Husk Carbonizer in Colombia

01 Problems & Challenges

- Resource Wastage: A large amount of rice husk goes unrecycled, leading to significant waste.

- Environmental Pollution: Rice husk is either piled up or burned, causing air pollution and land occupation.

02 Change in Goals

- Environmental Needs: The customer wanted to recycle rice husk to reduce pollution and promote sustainable farming.

- Economic Value: The customer aimed to turn the rice husk into valuable products for revenue generation.

03 Action Solution

- Customized Solution: Beston Group supplied the BST-50 rice husk pyrolysis unit with a drying system to improve efficiency.

- Technical Support: Beston Group engineers provided on-site guidance for smooth installation and setup.

04 Results Achieved

- Project Successfully Delivered: The equipment is now installed and fully operational, with a smooth and timely setup.

- Resource Utilization: Rice husk is now converted into biochar for barbecue fuel and soil improvement, creating a sustainable income stream.

Understand Carbonized Rice hull Benefits

Agriculture

- Soil Improver: Rice husk biochar is rich in carbon and trace elements. It improves soil structure. In addition, it enhances water and nutrient retention, which in turn promotes plant growth.

- Seedling Cultivation: Rice husk biochar can be used as a growing medium for seedlings. This helps to promote root growth and create a better environment for planting.

Construction

- Building Material Additive: Rice husk biochar is used as an additive in building materials. It enhances compressive strength, resistance to corrosion, and overall environmental performance.

- Asphalt Material Additive: Furthermore, rice husk biochar is also used in asphalt materials. It improves both durability and aging resistance, making it ideal for road construction.

Animal Husbandry

- Animal Feed Additive: Rice husk biochar can be added to animal feed. It absorbs harmful substances and promotes digestion. As a result, it increases feed utilization, which supports healthier animal growth.

- Bedding Additive: As a bedding additive, rice husk biochar effectively absorbs ammonia and other odors. This helps keep the air in animal barns fresh, thus improving the comfort of the animals’ living environment.

Industry

- Industrial Fuel: Rice husk charcoal can replace traditional fuels in industrial production processes. This reduces dependence on fossil fuels and promotes cleaner energy usage, leading to a more sustainable industrial process.

Consumer Goods Processing

- Barbecue Charcoal: Rice husk charcoal has a high burning temperature and long burning time. Moreover, it is free of harmful chemicals, which makes it a popular choice for barbecue charcoal production.

- Refined Charcoal Products: We support the production of specialized charcoal products, such as hookah charcoal and activated charcoal. However, we do not provide equipment for further processing of these products.

Working Process of Rice Hull Carbonizer

01 Rice Husk Pretreatment

- Drying: The moisture content of rice husks is reduced to below 20%, improving the efficiency of pyrolysis in the rice husk charcoal machine.

- Screening: Rice husks are screened to ensure the proper size for smooth feeding into the system and stable operation.

02 Rice Husk Pyrolysis

- Moisture Removal: As the temperature rises, water is expelled from the rice husks.

- Gas Release: Between 200–500℃, volatile gases are released. These gases serve as heating fuel for the rice husk carbonizer.

- Charcoal Formation: Above 500℃, the rice husks transform into stable biochar in the biochar reactor.

03 Combustible Gas & Flue Gas Utilization

- Direct Treatment: A part of the gases is sent to the tail gas system after cyclone dust removal.

- Heat Exchange: Some of the gases enter the air-to-air exchanger, where they preheat the combustion air.

- Drying Support: Another portion of the gases enters dryer to provide heat, drying the rice husks before they enter the reactor.

04 Rice Husk Charcoal Discharge

05 Exhaust Gas Treatment

Rice Husk Carbonization Project Promotes Sustainable Agriculture

Rice hull carbonizer facilitates cooperation between farmers, agricultural processing plants, and carbon removal companies. This creates a circular economy within the region. It not only achieves carbon removal and resource recycling, but also promotes the coordinated development of agriculture, the environment, and the economy.

Rice Farmers

- Advanced Technology Introduction: Implementing biochar carbon removal projects introduces advanced agricultural techniques, soil health monitoring, and scientific planting methods, helping farmers improve the sustainability of agricultural production.

- Increased Economic Benefits: By using rice husk biochar, farmers can improve crop yield and quality, leading to higher economic returns through the sale of high-quality produce to processing plants.

Agricultural Processing Plants

- Low-Carbon Product Sales: By incorporating biochar, agricultural products can meet the growing demand for sustainable products, adding low-carbon value and enhancing competitiveness in the market.

- Sustainable Waste Management: Agricultural processing plants provide rice husks to carbon removal companies, solving waste disposal issues and reducing environmental costs by avoiding traditional methods like burning and landfilling.

Carbon Removal Companies

- Regional Economic Growth: Carbon removal companies create jobs during both the construction and operational phases of rice husk charcoal making machine, bringing social benefits and attracting sustainable investments.

- ESG Responsibility Fulfillment: By working with farmers and processing plants, carbon removal companies contribute to local economic and social welfare, supporting green agriculture and fulfilling ESG (Environmental, Social, and Governance) objectives.

How Rice Husk Carbonizer Reduce Greenhouse Gas Emission?

Reduce Nitrogen Oxide Emissions

The use of chemical fertilizers is one of the important sources of nitrogen oxide emissions in agriculture. Rice husk biochar is a natural organic fertilizer. Its application helps improve soil fertility. This reduces the need for conventional fertilizers, thereby lowering nitrogen oxide emissions.

Mitigate Methane Emissions

Large amounts of rice husk disposal can lead to methane emissions. The rice husk charcoal machine achieves a large-scale reduction of rice husk, thereby reducing this part of emissions. Not only that, although the biomass pyrolysis process produces methane. It is recycled for energy supply as a sustainable biofuel.

Increase Soil Carbon Sequestration

The addition of rice husk biochar enhances soil carbon sequestration. Acting as a stable carbon element, rice husk biochar effectively stores carbon in the soil for an extended period. Consequently, carbon that would otherwise be released into the atmosphere is securely stored in the soil, reducing greenhouse gas emissions.

Reshaping Sustainable Agriculture With Rice Hull Carbonizer

Rice hull carbonizer is revolutionizing agriculture by converting rice husks into high-quality biochar. This not only improves soil health and boosts crop yields but also sequesters carbon, contributing to a greener future. Join us in promoting circular economy practices, reducing waste, and enhancing sustainability in farming. Follow our Linkedin page for insights and updates on how this technology is shaping the future of agriculture!