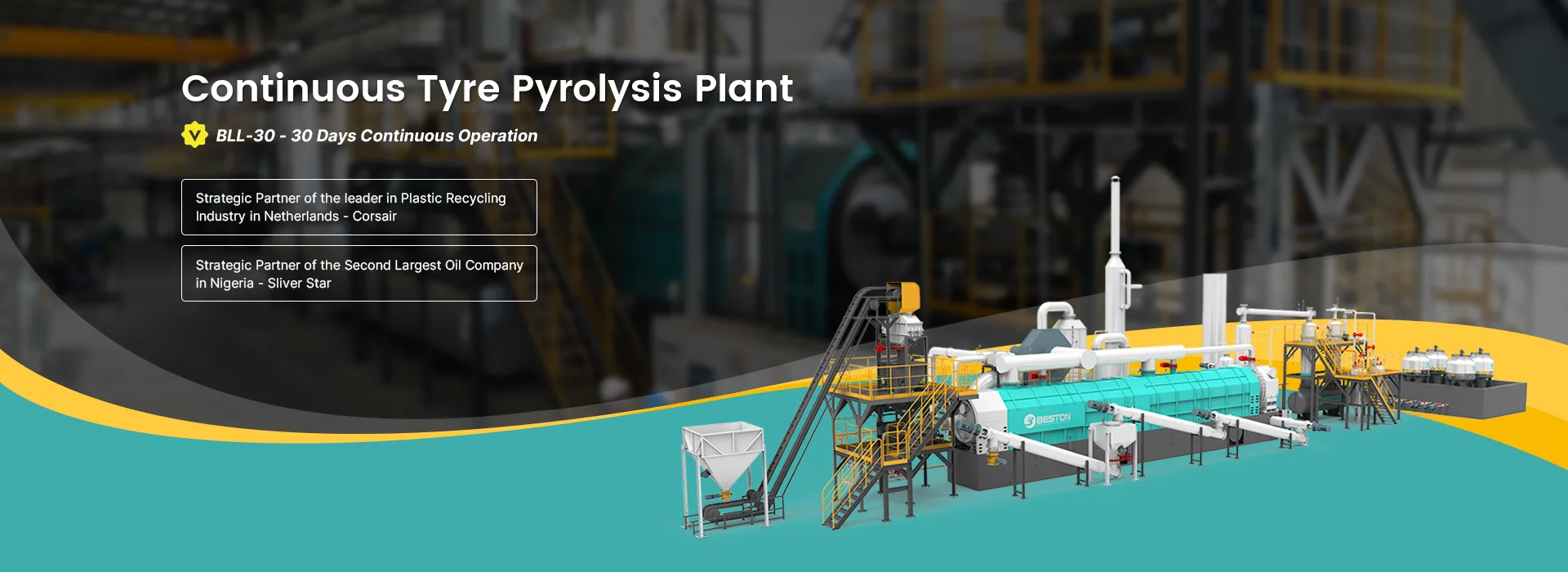

Continuous tyre pyrolysis plant offers a highly efficient and scalable solution for converting waste tyres into valuable resources such as fuel oil and recovered carbon black. Compared with traditional batch systems, continuous pyrolysis technology provides higher automation, lower operating costs, and more stable product quality. As global demand for sustainable recycling solutions continues to rise, continuous waste tyre pyrolysis plant is becoming an attractive option for investors seeking long-term profitability and environmental compliance. This article provides a clear overview of its working process, product value, and the key factors to consider before making an investment.

Parameters & Equipment Overview of Continuous Tyre Pyrolysis Plant

| Model | BLL-30 |

| Manufacturer | BESTON |

| Time to Market | 2025 |

| Motor Brand | Chinese brand |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h |

| Working Method | Fully Continuous |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Materil | 304/310S Stainless steel |

| Reactor Life Span (Years) | 5-8 |

| Guarantee (Months) | 12 |

| Delivery Time (Calendar Days) | 60-90 |

| Land Space Required (L*W*H*m) | 70*20*10 |

| Packing | 20*6*3m in bulk+13*40HQ |

| Installation Period (Calendar Days) | 90 |

| Packing | 20*6*3m in bulk+13*40HQ |

| Installation Period (Calendar Days) | 60-90 |

Technological Innovation of BLL-30 Continuous Tyre Pyrolysis Plant

30 Days Continuous Operation

Oil-gas direct spray mixing condensation technology achieves rapid cooling. Furthermore, this design prevents secondary polymerization of olefin compounds from clogging the oil gas pipelines. This avoids frequent downtime for maintenance, providing a solid guarantee for the entire line to achieve continuous and stable operation for 30 days.

55% ↓ Fuel Use, 50% ↓ Emissions

BLL-30 continuous tyre pyrolysis plant reintroduces 80% of high-temperature flue gas into the combustion chamber. It mixes evenly with hot air from the burner and then heats the reactor. The remaining 20% of high-temperature flue gas heats fresh combustion air, which supplies oxygen to the furnace. Together, these two methods cut energy consumption by 55% and reduce emissions by 50%.

80% ↓ Manual Work

The combustion system uses a multi-medium automatic burner valve assembly. Combined with hot-air heating, this design automatically adjusts the fuel mix to suit different fuels, achieving temperature control accuracy of ±10℃. With continuous feeding and discharging, only two operators are required for BLL-30 continuous waste tyre pyrolysis plant, reducing manual intervention by 80%.

Video Demonstration of Technical Process

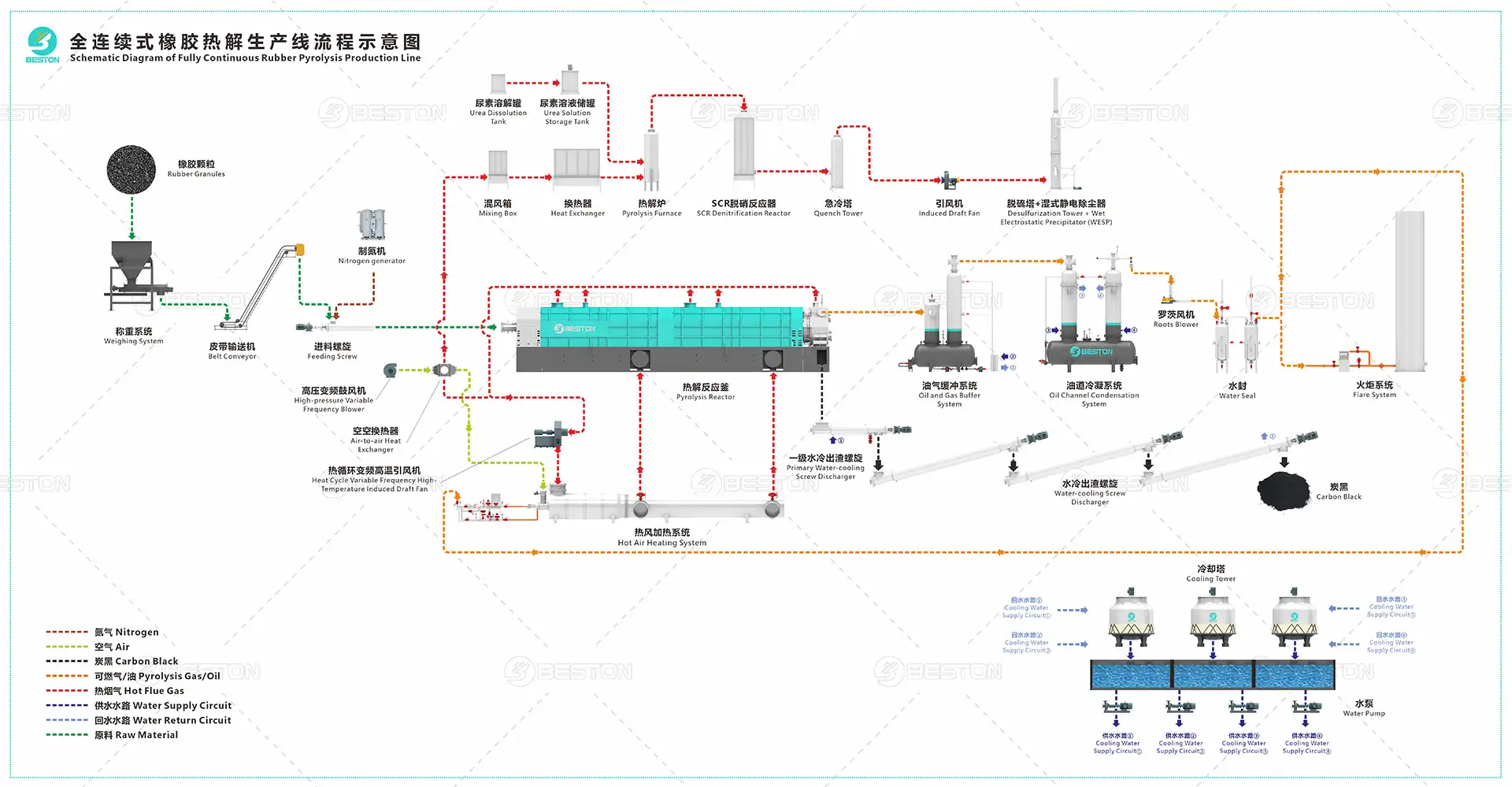

Working Process of Continuous Tyre Pyrolysis Plant

01 Preheating

- The burner starts operating. Then, hot-air heating system starts raising the reactor temperature.

- Preheating takes 3–4 hours, and feeding can begin once the reactor reaches 300–350°C.

02 Feeding

- Large-incline belt conveyor feeds tyre rubber powder (1–5 mm) into the sealed silos, where the nitrogen system removes excess air.

- The powder then enters the weighing system through the first screw feeder for real-time feed monitoring.

- Finally, it is delivered into the reactor through the second screw feeder.

03 Pyrolysis

- Guided by flow guide plates, tyre powder is evenly heated from feeding end to discharge end.

- The polymer molecular bonds break, forming small-molecule oil gas. Meanwhile, the solid residue becomes carbon black.

- The high-temperature flue gas from pyrolysis process becomes waste heat recovery resource for continuous pyrolysis plant.

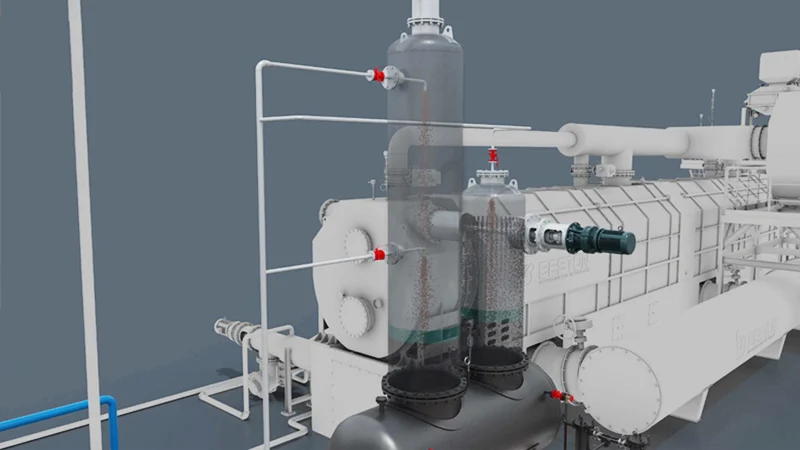

04 Condensation

- Oil gas passes through a manifold to remove heavy hydrocarbon impurities. Then, heavy oil settles into the residue oil tank.

- Light oil gas is condensed by two condensers and collected as liquid oil in the storage tank.

- Non-condensable gas (syngas) goes through two water seals and then returns to the combustion chamber as supplementary fuel.

05 Discharging

- Carbon black in the reactor is conveyed through the discharge screw into the water-cooled discharging system.

- It is cooled through multiple water-cooled discharge screws and then collected in the water-cooled carbon black storage tank.

06 Exhaust Gas Treatment

- After waste-heat recovery, the flue gas and other exhaust gases enter the exhaust treatment system.

- The exhaust undergoes cooling, dust removal, desulfurization, and denitrification.

- Exhaust gases from a fully continuous tyre pyrolysis plant can meet EU standards after treatment.

Workflow Diagram of Continuous Waste Tyre Pyrolysis Plant

Dual Benefits from Continuous Tyre Pyrolysis: rCB & TPO

Recovered Carbon Black (rCB)

Tyre Pyrolysis Oil (TPO)

Recovered Carbon Black (rCB) is a high-value product transformed from the initial carbon black in tires through grinding and granulation processes. It has a higher specific surface area and better particle size distribution, making it suitable for various high-end applications.

Recycled Tire Manufacturing:rCB enhances the strength and wear resistance of tires. By using rCB, tire manufacturers can achieve a circular economy and reduce dependence on fossil resources.

Rubber Products:rCB is widely used in the production of seals, gaskets, and other rubber products. It helps rubber manufacturers improve product quality and promote sustainable transformation.

Coatings and Inks:rCB is an important additive in coatings and inks. It can increase the adhesion and durability of coatings, especially in high-performance products.

Tyre Pyrolysis Oil (TPO) is a high-value byproduct generated from tire pyrolysis plant. It can be used directly as fuel or further processed into diesel and naphtha.

Industrial Fuel:Pyrolysis oil can be used as fuel for industrial boilers and power plants, replacing traditional petroleum fuels, providing an environmentally friendly and economical energy solution.

Heavy Machinery Fuel:Non-standard diesel is widely used as fuel for heavy machinery, trucks, and other industrial equipment. It is an excellent choice for heavy machinery operators to reduce operating costs.

Chemical Raw Materials:Naphtha is widely used in the chemical and petrochemical industries. Chemical plants and refineries can utilize it as a raw material, reducing reliance on traditional petroleum.

Advantages of Continuous Tyre Pyrolysis Plant Over Batch Processing

Integrated Product Collection

Superior Carbon Black Quality

More Complete Pyrolysis Reaction

The key advantages of BLL-30 continuous tyre pyrolysis plant is simultaneous feeding and discharging. Compared to traditional batch pyrolysis, the continuous process efficiently and automatically collects oil, carbon black, and gas, eliminating the interruptions and repetitive operations of batch processing.

- Optimized Operating Cycle: Continuous pyrolysis can operate 24 hours a day without interruption, reducing downtime. This significantly increases production efficiency and shortens the production cycle.

- Reduced Labor Costs: The automated integrated collection system reduces the reliance on manual operations. The demand for operators is greatly reduced, optimizing overall operational costs.

The continuous pyrolysis process produces carbon black (rCB) of higher quality than batch processes, particularly in the key indicators of Toluene Permeability and Total Petroleum Hydrocarbon (TPH).

- Toluene Permeability : A higher toluene permeability gives carbon black better reactivity and dispersibility. This makes it ideal for high-performance applications such as tyres and advanced rubber products.

- TPH: A lower TPH value indicates fewer organic impurities. This improves the purity of the carbon black, enhancing the stability and long-term performance of the subsequent carbon black-based products.

Unlike whole tyres for batch system, continuous waste tire pyrolysis plant adopts tyre rubber powder. Finer powder provides larger surface area, ensuring more even heat distribution. Thus, it improves thoroughness of pyrolysis process.

- Reduced Feedstock Cost: Tyre rubber powder improves heat transfer efficiency, which allows full conversion of lower-grade or mixed waste tyres. Investors can source cheaper feedstock without sacrificing product quality.

- Higher Product Yield: More efficient thermal breakdown of granulated material increases the conversion rate of tyres into oil, gas, and carbon black. This maximizes resource recovery and boosts overall revenue from waste tyre.

Key Factors to Consider When Investing in a Continuous Tyre Pyrolysis Plant

Equipment Quality and Durability

The quality of materials, manufacturing processes, and structural design directly affects the stability and lifespan of a continuous waste tire pyrolysis plant. Durable and heat-resistant equipment reduces maintenance frequency and lowers operational risks.

Project Budget and Expected ROI

Investors should evaluate pyrolysis plant cost, inclduing equipment cost, installation expenses, operating costs, and local market demand for pyrolysis products . A clear return-on-investment assessment is essential for ensuring project feasibility.

After-sales Support and Operational Assistance

Continuous pyrolysis systems are technologically complex and require reliable technical support. Installation guidance, operator training, and spare parts supply help maintain stable plant operation and minimize downtime losses.

Environmental and Regulatory Compliance

Pyrolysis projects must meet local environmental and safety standards. Efficient exhaust-gas treatment systems—such as cooling, dust removal, and desulfurization—are vital for regulatory approval and long-term compliant operation.

From Quality to Compliance, Beston Group Supports Your Project Step-By-Step.

Toward a Cleaner and More Sustainable Future

Continuous tyre pyrolysis plant plays a vital role in the sustainable development of energy and manufacturing. This technology minimizes environmental impact while reducing reliance on traditional fossil resources. It supports a circular economy model, thereby improving industrial efficiency and promoting long-term ecological balance. As industries worldwide accelerate their transition to cleaner production and responsible energy use, adopting continuous pyrolysis solutions is not only an economic choice but also an environmental commitment. For more industry insights and the latest developments in sustainable technology, please follow our LinkedIn page.