Thermal Desorption Unit is reshaping the future of oil sludge management. With the ability to process up to 12,000 tons of oil sludge annually, it addresses both environmental and economic challenges. Through cutting-edge technologies, the unit converts hazardous waste into valuable fuel oil. Meanwhile, treated harmless residues can also be discharged safely. TDU breakthrough technology enhances operational efficiency, driving a major transformation in the oil industry. It also plays a pivotal role in reshaping the global landscape of resource disposal.

Global Thermal Desorption Project Deliveries by Beston Group

TDU in the Middle East

TDU in Southeast Asia

Project Information

- Customer Industry: waste recycling and disposal

- Waste Type: oil-contaminated soil

- Delivery Duration: 21th May 2023 – 10th Dec 2024

- Project Configuration: 1 sets of BLJ-16 thermal desoprion unit

- Processing Capacity: 10 tons/day

Project Outcome

- Phase: Equipment installation, commissioning, and operation training have been completed.

- Key Achievements: Jointly hosted a technical exchange meeting with the Best Group, enhancing the brand’s influence in the Middle East.

- Future Development: Expand tire processing lines and establish a leading local waste recycling center.

Project Information

- Customer Industry: alternative energy production

- Waste Type: chemical oil sludge, medical waste plastic

- Delivery Duration: 20th Oct 2023 – 19th Oct 2025

- Project Configuration: 2 sets of BLJ-16 pyrolysis unit

- Processing Capacity: 10 tons/day

Project Outcomes

- Phase: Equipment installation, commissioning, and operation training have been completed.

- Key Achievements: Successfully reduced hazardous waste treatment compliance costs.

- Future Development: Expand tire processing lines and establish a leading local waste recycling center.

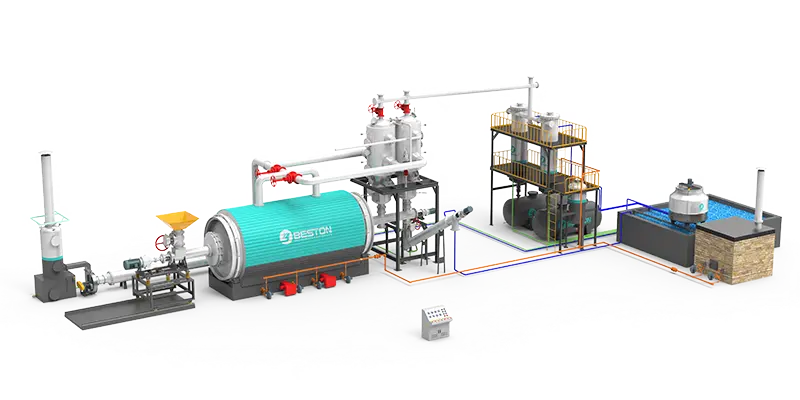

Thermal Desorption Unit for Sale in Different Operating Designs

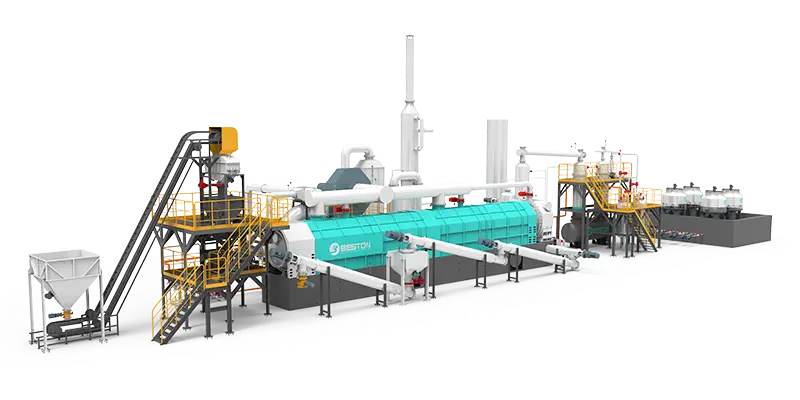

Continuous Type: BLL-30

- Process 12,000 tons oil sludge annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

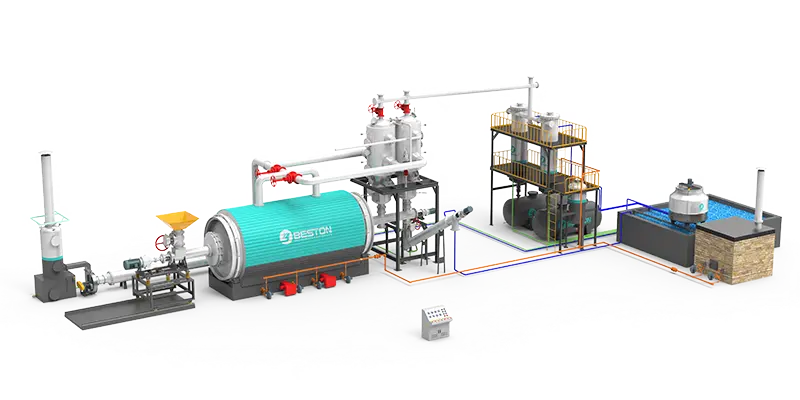

Batch Type: BLJ-20

- Process 7,500 tons oil sludge annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 6,000 tons oil sludge annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 TDU | BLJ-16 Standard | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge: 20-25t/d | 16-18t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+8*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 60 |

Triple Combination Process Increases TDU Production Efficiency by 200%

NO.1 Thermal Washing

Improves Oil Purity

This technology involves mixing oil sludge with hot water and emulsifiers. Through heating and emulsification, the oil is washed away from the sludge surface, removing most impurities.

NO.2 Decanter Centrifuge

Efficient Solid-Liquid Separation

Using centrifugal force, oil, water, and solid residues are separated. This ensures that the residual solids contain less than 5% oil, making them ready for further conversion in the pyrolysis reactor.

NO.3 Thermal Desorption

Maximizes Products Yield

Thermal desorption process converts high-purity oil sludge into oil, gas, and non-hazardous residue. Due to the reduction of impurities in the feedstock, the reaction becomes more efficient, significantly increasing products yield.

BLJ-20: Performance Upgrade for Batch Thermal Desorption

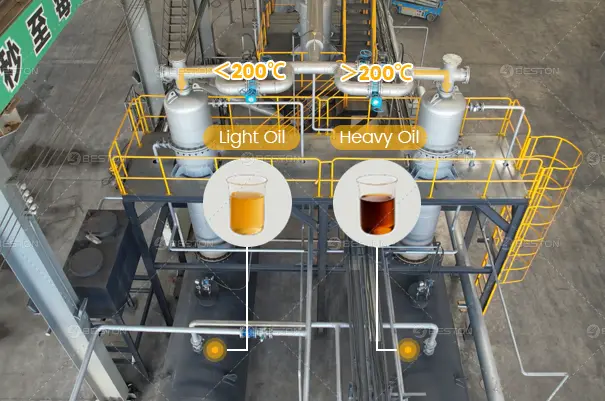

2 Oil Grades, 1-Step Separation

This technology separates pyrolysis vapors by boiling point. Naphtha (<200 °C) to the light oil tank; non-standard diesel (>200 °C) to the heavy oil tank. The benefits include:

- Simplified Process Flow: Eliminates the need for downstream distillation equipment, reducing system complexity, footprint, and additional energy consumption.

- Higher Oil Value: Produces clearly graded oil products with improved consistency and usability, enhancing overall product quality and economic returns.

50%↑ Processing Capacity

BLJ-20 reactor, with dimensions of ø2800 × 10000 mm, promotes processing capacity from 16–18 tons to 20–25 tons per batch. The benefits include:

- Enhanced Operational Efficiency: Higher batch capacity reduces cycle frequency and handling operations, improving overall plant productivity.

- Lower Unit Processing Cost: Higher throughput spreads fixed costs across larger volumes, improving cost control and project-level returns.

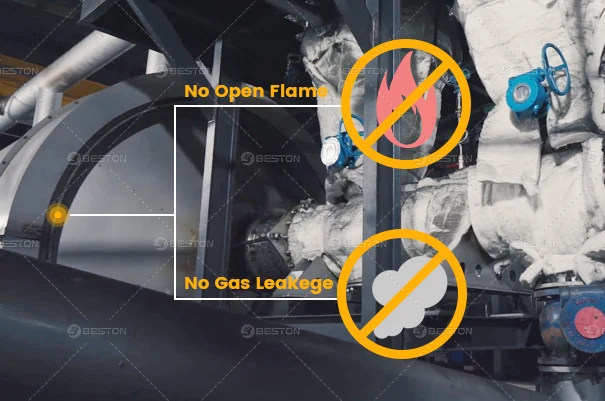

No Open Flame, No Oil Gas Leakage

BLJ-20 TDU integrates thermal dynamic sealing with high-temperature insulation to fully isolate pyrolysis gases, ensuring leak-free operation without open flames. It brings:

- Improved Operational Safety: Prevents oil-gas leakage and uncontrolled ignition, significantly reducing fire and explosion risks during operation.

- Lower Thermal Risk Exposure: Stable insulation performance minimizes heat loss and thermal hazards, supporting safer, more reliable long-term plant operation.

BLL-30: Technological Breakthrough in Continuous Thermal Desorption

30 Days Continuous Run

This technology prevents olefins from polymerizing and blocking oil-gas lines, ensuring the thermal desorption unit operates continuously for 30 days without downtime. The benefits include:

- Minimized Downtime Losses: Guarantees uninterrupted pyrolysis, avoiding revenue loss and delivery delays due to shutdowns.

- Improved ROI: With lower failure rates, reduced repair, parts, and labor costs, the system maintains stable output, leading to consistent, long-term returns.

55% Less Fuel Use, 50% Less Emissions

This system recycles 80% of the furnace flue gas, mixing it with hot air to efficiently heat the tdu unit, while the remaining 20% preheats fresh combustion air. The key advantages are:

- Fuel Savings: Reusing heat cuts fuel consumption by 55%, significantly reducing operating costs.

- Regulatory Compliance: The exhaust meets EU emissions standards, ensuring legal operation and avoiding potential fines.

80% Less Manual Work

The furnace automatically adjusts to different fuels, maintaining ±10°C precision. Combined with continuous feeding and discharging, this system provides:

- Reduced Workload: One-touch operation eliminates the need for constant monitoring and adjustments.

- Labor Cost Savings: High automation requires just 2 operators, reducing the need for skilled labor and lowering staffing costs.

In-Depth Analysis of Thermal Desorption Technology

The working logic of thermal desorption unit is similar to pyrolysis unit. It uses high temperature to increase volatility and thermal decomposition properties of pollutants, thereby removing them from solid matrices. Oily wastes contain petroleum components and volatile organic compounds (VOCs), which cause many hazards when treated irrationally. These hydrocarbon mixtures are more easily thermally decomposed from solid matrices under high temperature conditions. Therefore, thermal desorption system is an excellent choice for recycling oily wastes.

Oil Sludge Generation Across the Oil & Gas Value Chain

Crude Oil Drilling

Refinery Wastewater Treatment

Storage & Transportation

Oil sludge generated during oilfield operations typically contains high concentrations of hydrocarbons and solids. These wastes originate from drilling, well servicing, and surface spills.

- Oil-based Cuttings: Drill cuttings soaked with oil-based mud, often highly viscous and difficult to dehydrate.

- Waste Oil-based Mud: Used oil-based drilling fluids containing emulsified oil, chemical additives, and fine solids, no longer suitable for reuse.

- Oil-contaminated Soil: Surface soil polluted by crude oil leaks or spills during production and transport within oilfields.

Refining and petrochemical processes produce various types of oil sludge during wastewater treatment and oil separation. These sludges are often mixed with water, oil, and chemical residues.

- Oil Separation Sludge: Heavily polluted sediment from API separators and oil-water settling tanks, containing oil droplets and suspended solids.

- Flotation Scum: Oily foam and floatables generated during DAF (Dissolved Air Flotation) treatment, typically with high moisture and unstable composition.

- Biological Sludge: Residual sludge from aerobic or anaerobic treatment systems, rich in organic matter, microorganisms, and some residual oil.

During the storage and transportation of crude oil and petroleum products, oily sludge accumulates as a result of settling, corrosion, and operational discharge.

- Tank Bottom Sludge: Dense, sticky mixture of crude oil, rust, scale, and sediment deposited at the base of storage tanks after long-term use.

- Pipeline Sludge: Wax, asphaltene, and particulate buildup within pipelines, especially under low-temperature or high-viscosity conditions.

- Ship-generated Oil Sludge: Sludge produced onboard from fuel purification systems and oily bilge water treatment, subject to MARPOL Annex I regulations.

3 Core Values Brought by Thermal Desorption System

Harmless Treatment

Reduction

Resource Utilization

TDU unit not only helps enterprises avoid potential legal risks but also plays a positive role in advancing the green transformation.

- Avoiding Compliance Penalties: By using the unit, companies can avoid economic penalties from improper disposal of oil sludge and non-compliance with environmental standards.

- Promoting Industry Sustainability: By treating oil sludge in a harmless way, the unit helps reduce the overall carbon footprint of the industry, meeting increasingly stringent carbon tax policies.

Thermal desorption equipment industrial-scale recovery capabilities help enterprises reduces of oil sludge volume, generating economic benefits.

- Alleviating Environmental Pressure: Through reducing the volume of oil sludge, TDU effectively preventing environmental contamination caused by accumulation, while minimizing soil and water pollution.

- Creates New Income Streams: As environmental regulations tighten, more companies will seek professional, large-scale oil sludge treatment solutions. It creates new income streams for oil sludge thermal desorption service providers.

Thermal desorption unit transforms oil sludge into fuel oil and the harmless residues. They all have high application value:

- Fuel Oil: By converting oil sludge into fuel oil, companies can generate additional revenue by selling the fuel. Furthermore, fuel oil can be used for on-site energy generation or as an alternative energy source. In addition, fuel oil can be further processed at refineries to produce higher-quality products for resale.

- Harmless Residues: The residues from thermal desorption process become harmless materials. This not only resolves waste disposal issues but also reduces environmental burdens. Also, the harmless residues can be used as additives in road construction materials or as oil well anti-collapse filling.

Working Process of Thermal Desorption Unit: Step-by-Step Guide

Oily Waste Feeding

First, the oily hazardous waste is transported to the main furnace. Different liquid contents have different transportation methods:

- Liquid content below 40%: belt conveyor;

- Liquid content 40%–60%: shaftless screw;

- Liquid content above 75%: sludge pump.

Thermal Desorption Process

- As the temperature of pyrolysis reactor gradually increases, the long-chain petroleum hydrocarbon compounds in the oily waste begin to thermally decompose.

- In a high-temperature, micro-oxygen environment, the small-molecule hydrocarbon compounds formed by the reaction are gasified.

- The thermal desorption system removes volatile components that pose a threat to the environment, while the oily sludge forms harmless solid residues.

Fuel Oil & Syngas Separation

- Oil gas enters the header to separate heavy oil impurities.

- The condensable components in the oil gas enter the condenser to form fuel oil, which is stored in the oil tank.

- Water sealing purifies the non-condensable components in the high-temperature oil gas to form syngas containing CO and H₂.

- Syngas enters the combustion system, replacing fossil fuels to provide heat for the reaction.

Solid Residue Discharge

- After the oily hazardous waste in the reactor is fully reacted, the screw conveyor discharges the solid residue.

- The solid residue enters the water-cooled screw discharger.

- Cooling water exchanges heat with the high-temperature residue to reduce its temperature.

- After three-stage water-cooled discharge, the solid residue is cooled to 50–80 °C.

Waste Gas Treatment

Since oily waste is mostly hazardous waste, emission standards are relatively strict. Customers selecting a TDU unit often adopt a high-end exhaust gas treatment system.

- Heat exchangers first cool down the high-temperature waste gas.

- The cooled gas then enters the chemical tower for desulfurization and denitrification.

- Treated gas passes through an electrostatic precipitator and activated carbon dust collector for dust removal.

- Finally, the purified exhaust gas is discharged through the chimney.

Technical Advantages of Thermal Desorption Equipment

Avoid Coking

Coking can significantly reduce the heat transfer efficiency of the reactor, thus affecting production efficiency. Through the anti-coking technology of mechanical structure + thermal chemical cleaning, we can effectively remove coking materials. This technology can increase production efficiency by up to 200%, ensuring efficient production.

Clean Emission

We provide a high-end tail gas treatment system (standard for BLL-30). It uses advanced flue gas cooling, dust removal, desulfurization and denitrification technology. Through this system, the emissions of the equipment can meet EU environmental standards, ensuring that production emissions comply with local regulations of the project.

High Applicability

Beston thermal desorption unit has excellent adaptability and can handle various types of oily waste. According to the characteristics of the raw materials, the system can flexibly configure the feeding/conveying equipment, main furnace materials and other key components. This ensures that the treatment meets the customized needs of customers.

Health Protection

The equipment can use Morgan high-temperature ceramic wool, which is carcinogenic. The installation and construction are safer. This ensures the health and safety of operators in high-temperature working environments. This technology not only meets industry safety standards, but also reflects our high attention to the health of operators.

Beston thermal desorption unit has matured in operation in many oil sludge recycling projects around the world, including Nigeria, Oman, Chile, China, etc. The shipment and installation process of Beston machines went smoothly. And, these projects are running well. Beston equipment and services have been widely praised by customers. See the following cases.

What Are You Waiting For?

Thermal Desorption Unit represents a significant leap forward in waste management technology. By efficiently converting hazardous waste into valuable resources, it is helping industries achieve higher levels of sustainability. As the demand for eco-friendly solutions grows, TDU stands at the forefront of the transition to a more circular economy. It offers a reliable path for the oil industry and beyond to meet both environmental and economic goals. For more insights on oil sludge recycling and innovation, follow us on LinkedIn.