Oil sludge pyrolysis plant is rapidly becoming the preferred solution for treating oily waste. In the global petroleum industry, oil sludge is ecologically harmful and expensive to treat. Pyrolysis technology decomposes oil sludge through high temperatures. This method not only effectively reduces the volume of waste, but also obtains valuable pyrolysis oil. More importantly, oil sludge, a hazardous waste, can be treated harmlessly. Therefore, the machine’s unique environmental and economic benefits make it popular among investors.

Challenges in Oil Sludge Treatment

Compliance Pressure

Oil sludge is considered hazardous waste in many regions, and therefore, its dumping is prohibited. In recent years, the EU and the US have implemented strict regulations on hazardous waste streams related to the oil industry, resulting in high compliance costs and approval burdens.

Large Scale for Processing

As the oil industry expands, global oil sludge inventories have accumulated to over 1 billion tons. However, over 70% of this oil sludge remains undisposed. However, simple landfilling or incineration is unsustainable. Such a large scale presents logistical, storage, and disposal cost challenges.

Limited Utilization Options

Oil sludge has a wide range of composition, with a water content of approximately 30–90% and an oil phase of approximately 5–60%, often containing toxic organic compounds and heavy metals. The complex water, solid, and oil phases, as well as hazardous components, hinder direct utilization.

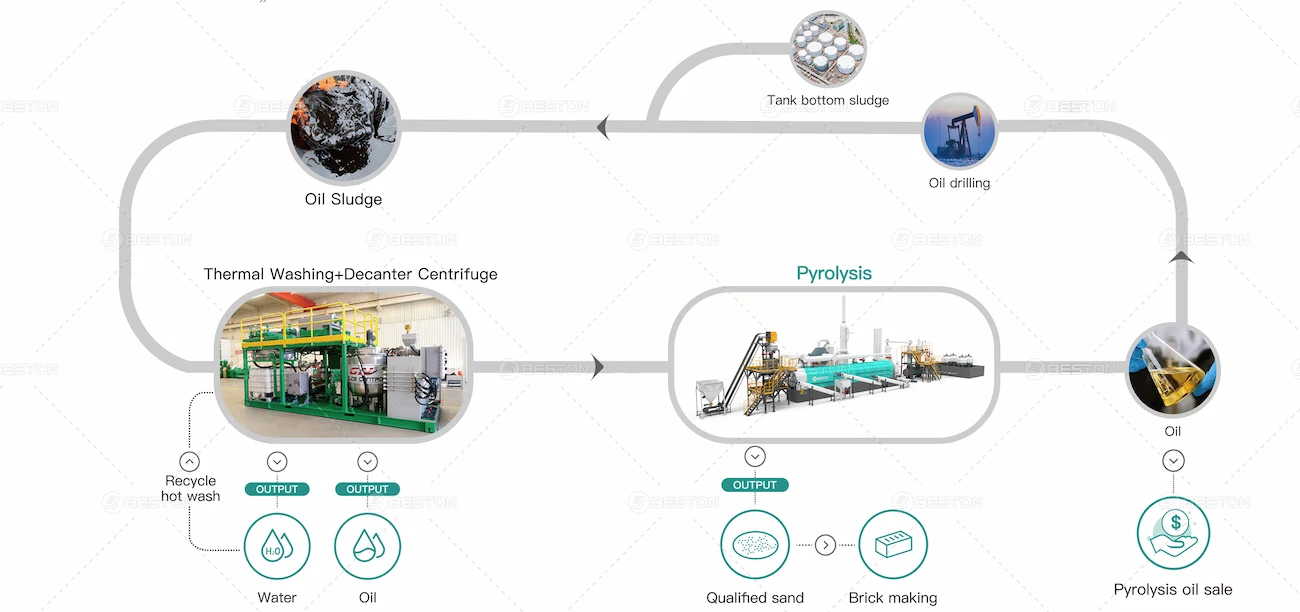

200% Boost in Oil Sludge Treatment: Triple-Process Combination

Centrifugation

Decanter centrifugation separates oil sludge into oil, water, and solids. Heavy particles and excess moisture are removed, providing cleaner oil sludge. This step reduces impurities for subsequent treatment processes.

Thermal Washing

It uses heat, water, and emulsifiers to treat oil sludge. Heating improves oil fluidity, while water removes salts and fine particles. The process enhances sludge purity and reduces equipment wear during thermal conversion.

Pyrolysis

In the oil sludge pyrolysis plant at 300–450 °C without oxygen, purified oil sludge breaks down into fuel oil, gas, and harmless residues. It maximizing recovery rate while ensuring high-efficiency operation.

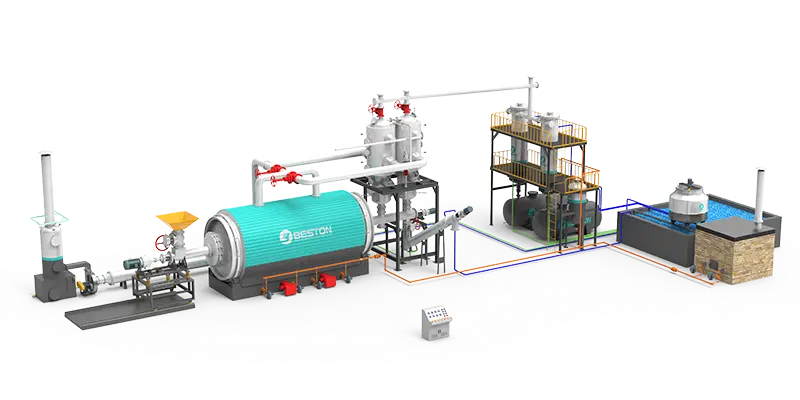

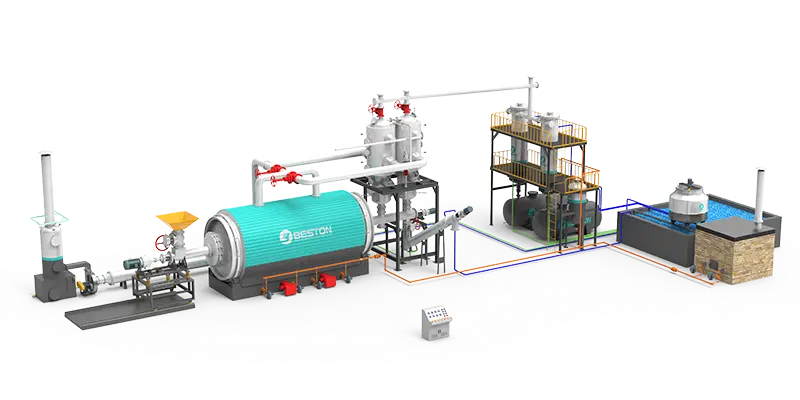

3 Models of Oil Sludge Pyrolysis Plant for Sale

There are 3 main modelss of oil sludge treatment plant, namely batch and continuous pyrolysis equipment. These 3 models of equipment have their own characteristics in terms of treatment methods, production capacity and operational complexity.

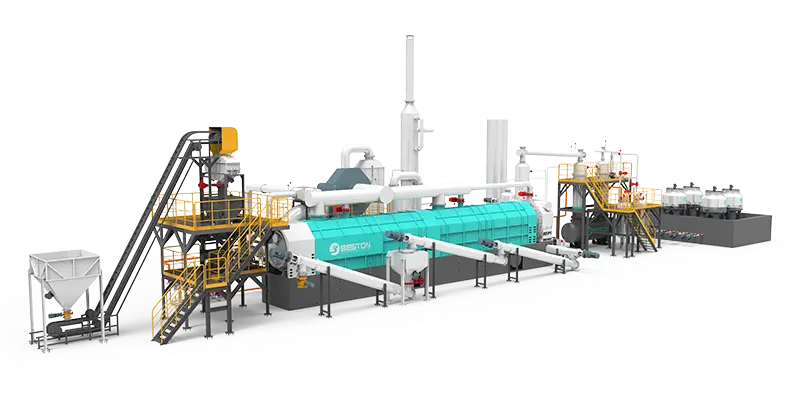

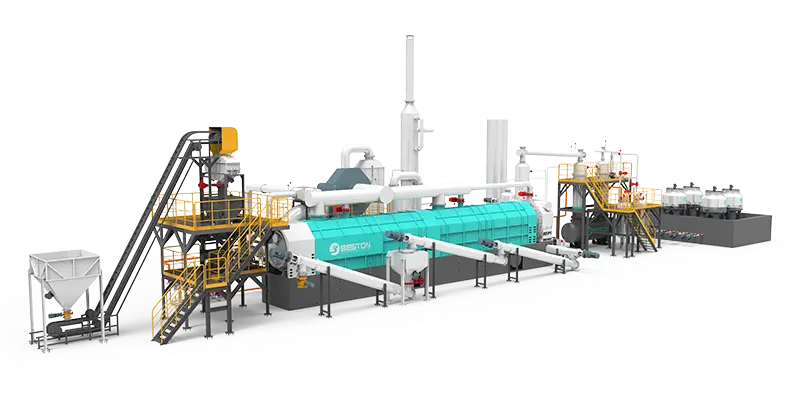

Continuous Type: BLL-30

- Process 12,000 tons oil sludge annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

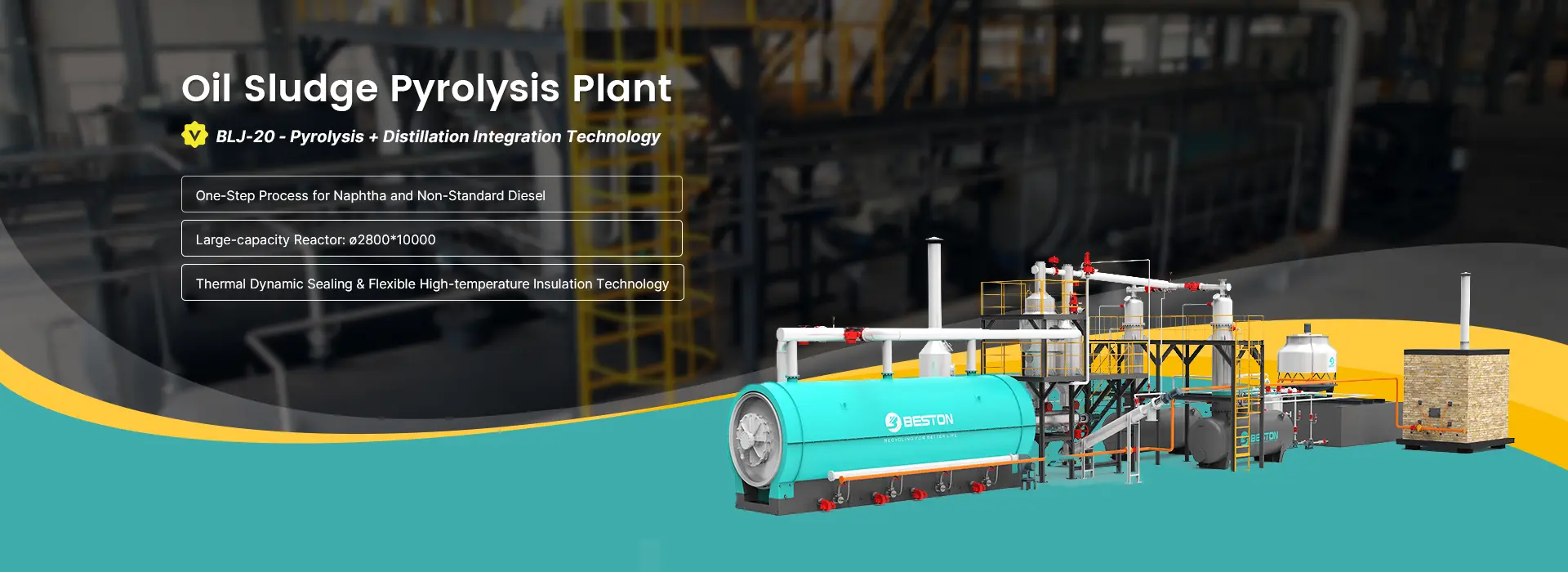

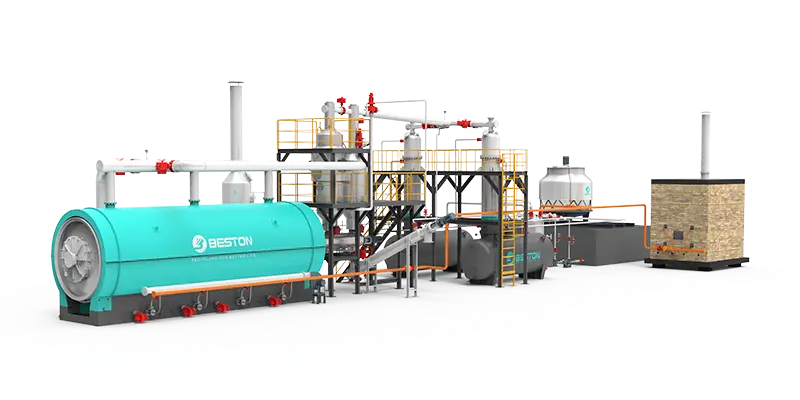

Batch Type: BLJ-20

- Process 7,500 tons oil sludge annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 6,000 tons oil sludge annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 TDU | BLJ-16 Standard | BLJ-16 ULTRA |

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge: 20-25t/d | 16-18t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+8*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 60 |

Cutting-Edge Technology of Oil Sludge Pyrolysis Plant

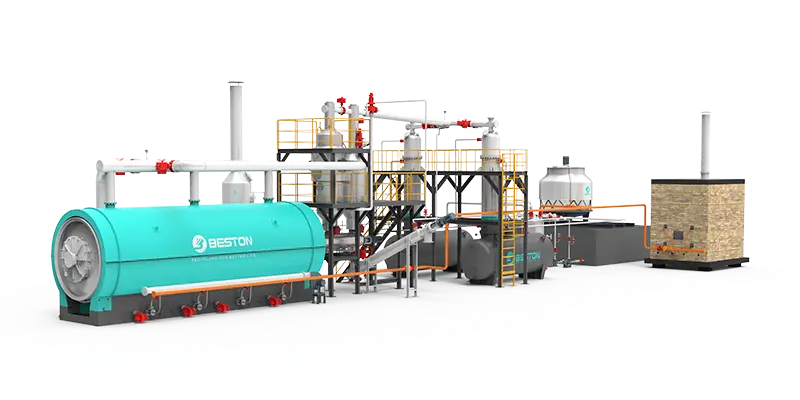

Technological Innovation of BLJ-20

Technological Breakthrough of BLL-30

50% Higher Throughput

The ø2800×10000 reactor of BLJ-20 oil sludge treatment plant increases daily processing capacity. The oil sludge processing capacity has been upgraded from 16–18 tons per day to 20–25 tons per day. Higher throughput improves productivity and makes waste conversion more efficient and reliable.

One-Step to Get Naphtha & Non-standard Diesel

Integrated fraction distillation separates naphtha (<200 °C) and non-standard diesel (>200 °C) in a single process. It improves oil quality, increases market value. Meanwhile, this design reduces operational costs by eliminating extra equipment and saving energy.

Maximum Safety & Comfort

Advanced sealing and high-temperature insulation prevent oil vapor leaks and eliminate open flames. Therefore, thermal hazards are minimized. This design ensures safe, stable, and comfortable operation, reducing risk and supporting continuous production.

30-Day Continuous Operation

in BLL-30 oil sludge pyrolysis plant, oil-gas spray condensation technology rapidly lowers temperature. It prevents olefin polymerization and avoids pipeline blockage. Thus, this design increases condensation efficiency and supports continuous operation for 30 days without shutdown.

55% Fuel Savings, 50% Emission Reduction

A stainless-steel induced draft fan recycles 80% hot flue gas back to the combustion chamber. Mixed with 1000–1300 °C hot air, it efficiently heats pyrolysis reactor. The remaining 20% preheats fresh air. This design saves 55% fuel and reducing exhaust emissions by 50%.

±10 °C Precision, 80% Less Manual Work

Automatic combustion valves and hot air recirculation precisely regulate furnace temperature within ±10 °C. The system adapts to various fuels, stabilizes heating conditions. Combined with continuous feeding and discharging, this design reduces manual adjustments by 80%.

Successful Case: Oil Sludge Treatment Plant in Oman

01 Problems & Challenges

The Oman customer faced increasing regulatory pressure, as traditional oil sludge disposal methods were no longer compliant and posed potential fines and reputational risks. The client needed a safer, more efficient, and sustainable solution foroil sludge treatment.

02 Change in Goals

The customer aimed to shift from “simple disposal” to compliant, harmless treatment. Objectives included improving operational efficiency and safety, adopting eco-friendly pyrolysis technology, and enhancing corporate environmental responsibility to build trust and future business opportunities.

03 Action Solution

The Oman customer introduced Beston Group’s advanced oil sludge pyrolysis plant and thermal desorption unit. The system provides safe, stable, and compliant treatment, while its user-friendly design allows employees to operate it efficiently. Key installations included the reactor, corrugated plates, oil-gas condenser, and flue gas pipeline, ensuring efficient thermal processing and controlled emissions.

04 Results Achieved

The project enabled legal and compliant treatment, achieving volume reduction and resource recovery. Pyrolysis oil recycling added economic value, operational safety was enhanced, and the customer strengthened its environmental reputation with authorities and clients. Eco-friendly, high-efficiency operation demonstrates a sustainable and high-performing solution for oily sludge treatment.

Oily Waste Treated by Oil Sludge Pyrolysis Plant

Crude Oil Extraction

- Oil-based Drilling Cuttings: generated during oil drilling, containing oil-based drilling fluid, rock cuttings and silt, with complex composition and high oil content.

- Operational Sludge: generated during oilfield maintenance operations. Contains oil, water, silt and chemical additives, etc.

Oil Storage & Transportation

- Tank Bottom Sludge: from the bottom sediment of crude oil storage tanks. Contains heavy oil, water, silt and metal impurities.

- Oil-contaminated Soil: formed by the mixture of crude oil leakage and soil, silt, etc. Contains high concentration of oil and environmental impurities.

Oil Refining

- Oil-water Separation Sludge: from the oil-water separator of the refinery. Contains oil, water and suspended solids, as well as some heavy metals.

- Floating Sludge: formed when flotation is used to treat refinery wastewater. Contains floating oil and fine suspended matter.

Sustainable Applications of Oil Sludge Pyrolysis Products

Fuel Oil

- Pyrolysis Oil: Used as industrial heating fuel for boilers of cement plants, smelters, brick factories, etc..

- Non-standard Diesel: Can power construction machinery, ships, or generators after simple refining.

- Naphtha: Acts as a valuable chemical feedstock for producing plastics and other petrochemical products.

Harmless Residue

- Construction Filler: Mixed with cement or asphalt to enhance strength and durability.

- Permeable Bricks: Processed into eco-friendly paving materials for urban drainage systems.

- Oil Well Backfill: Used as anti-collapse filler in drilling operations to stabilize well walls.

Step-by-Step Analysis: Oil Sludge Treatment Process

01 Feeding

02 Pyrolysis

03 Condensation & Syngas Recovery

Manifold Separation: Hydrocarbons enter the manifold. Heavy oil impurities separate and return to the main reactor by the screw system.

Condensation: Condensable vapors cool in the condenser. They form pyrolysis oil, which flows into storage tanks.

Syngas Recovery: Non-condensable gas passes through water-seal purification and returns as syngas to fuel the reactor, providing heat for continuous operation.

04 Residue Discharge

05 Exhaust Gas Treatment

Advantages of Beston Oil Sludge Pyrolysis Plant

Safety Protection System

Before and after the reaction, the nitrogen system introduces inert nitrogen into the main furnace to remove excess oxygen and pyrolysis oil gas, preventing flash explosions. Additionally, when overpressure occurs, the main furnace automatically opens the safety valve to release pressure, avoiding equipment failure due to overpressure.

Unique Sealing Design

Oil sludge pyrolysis plant adopts a combined floating seal made of carbon fiber and high-temperature soft filler. Compared to traditional graphene filler seals, it is more resistant to high temperature, corrosion, and wear, ensuring the system’s sealing performance and long-term stable operation.

Advanced Heating Method

The hot air heating method ensures more uniform heating and precise temperature control. Compared to traditional direct heating, it is more energy-saving and environmentally friendly. It also reduces energy consumption by 20%-30% while enhancing the safety and efficiency of the oil sludge treatment plant.

Anti-coking Design

In the batch system, the material rotates synchronously with the friction block, improving thermal conductivity and slowing down coking. The continuous equipment uses hot air heating combined with high-temperature catalysts to prevent coking from overheating. Additionally, a mesh chain friction structure is included to efficiently remove coke.

How Oil Sludge Pyrolysis Plant Promotes Sustainable Development?

Generate Diversified Revenues

- Processing Fee Revenue: Oil sludge pyrolysis plant can form centralized processing centers, charging processing fees through specialized processing services. This generates stable direct economic returns.

- Policy and Financial Support: Oil sludge treatment projects can access financial resources from multiple channels, including environmental subsidies, policy incentives, and green financing. This enhances project profitability.

Promote Green Industrial Production

- Environmental Risk Control: Pyrolysis of oil sludge prevent soil, water, and air pollution caused by indiscriminate landfill or incineration of oil sludge, ensuring industrial production complies with environmental regulations.

- Improve Health and Safety: Safe, controlled, closed systems reduce the risk of harmful emissions from waste streams to surrounding communities. This enhances corporate social responsibility and health care.

Promote Circular Economy Development

- Low-Carbon Transition: Oil sludge treatment process reduces dependence on traditional fossil fuels, helping companies achieve carbon reduction targets and transition to low-carbon production.

- Resource Recycling: Byproducts generated by pyrolysis, such as fuel oil and harmless residues, can be used in a closed-loop manner in industries such as industry and construction, improving resource utilization and fostering a circular economy model.

Projects of Beston Oil Sludge Treatment Plant All Over the World

Beston Group provides integrated solutions for oil sludge pyrolysis plant. The solution includes covering project design, equipment manufacturing, and installation delivery. Our pyrolysis projects have been successfully implemented in 180+ locations worldwide. Each project ensures safe, compliant, and efficient oil sludge processing, transforming hazardous waste into fuel oil and harmless residues. With Beston Group’s turnkey service, clients enjoy streamlined operations, sustainable waste management, and a reliable pathway to circular economy and environmental compliance. Here are some cases for your reference:

Join the Sustainable Oil Sludge Recovery Movement

Oil sludge pyrolysis plant plays a key role in transforming hazardous waste into valuable resources. By adopting advanced pyrolysis technology, companies can produce fuel oil, recover harmless residues, and reduce environmental impact. Join the movement to promote circular economy, support low-carbon industry, and contribute to a safer, cleaner community.Follow our LinkedIn page for more updates on sustainable oil sludge recovery and best practices.