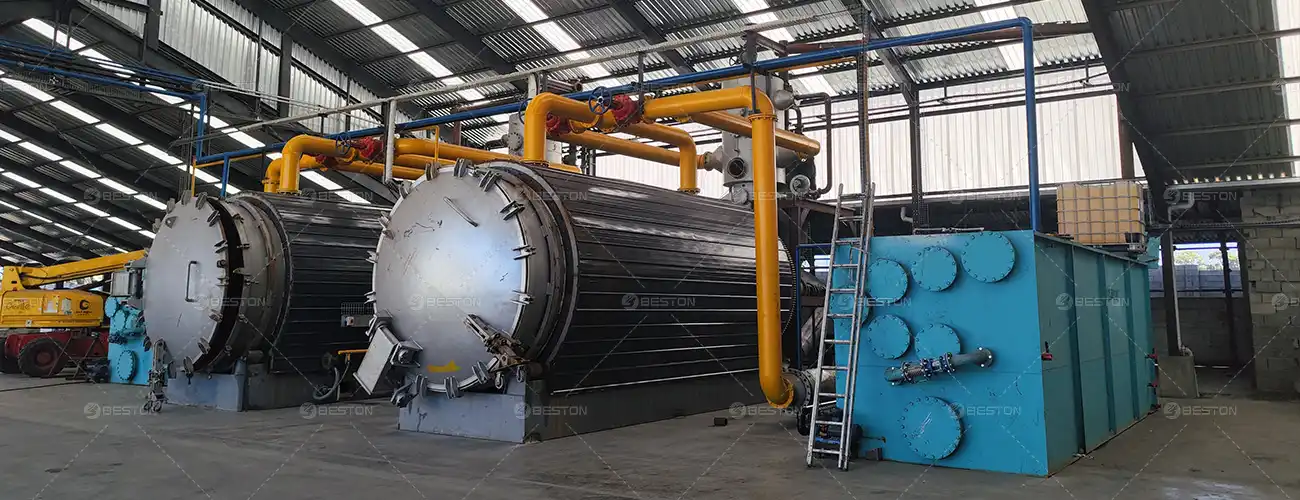

Pyrolysis Project in Southeast Asia – Converting Hazardous Waste into Alternative Fuel

1. Challenges Faced The project is located in Southeast Asia, where the client operates industrial incineration systems that rely heavily on auxiliary fuels. In daily operation when treating plastics and oil sludge, the client has long faced two major challenges: High fuel costs: Conventional auxiliary fuels are expensive and subject to price volatility. It significantly increasing the long-term operating costs …

Read morePyrolysis Project in Southeast Asia – Converting Hazardous Waste into Alternative Fuel