1. Project Background & Challenges

This project, located in South Africa, addresses the need for efficient processing of plastic and rubber waste. The customer’s plant faced two major challenges:

- The large amount of non-recyclable waste plastic and rubber needed to be reduced;

- The smelting plant’s fuel costs were high, necessitating the identification of more cost-effective energy alternatives.

Efficient waste processing not only benefits the environment but also reduces energy costs and alleviates production pressures.

2. Goal for Change

To address the current waste stream accumulation and energy cost challenges, South African customer urgently needs a solution can simultaneously address both challenges. Through research, the customer identified a pyrolysis plant as the most suitable solution. It can achieve:

- Reduce waste volume: Advanced pyrolysis technology converts waste plastic and rubber into fuel oil, syngas, and harmless residue, effectively reducing waste volume.

- Reduce energy cost: Pyrolysis oil can replace traditional, high-cost energy sources such as natural gas and electricity. Syngas allows the pyrolysis plant to be self-sufficient.

Thus, energy costs can be reduced, particularly in smelting plants.

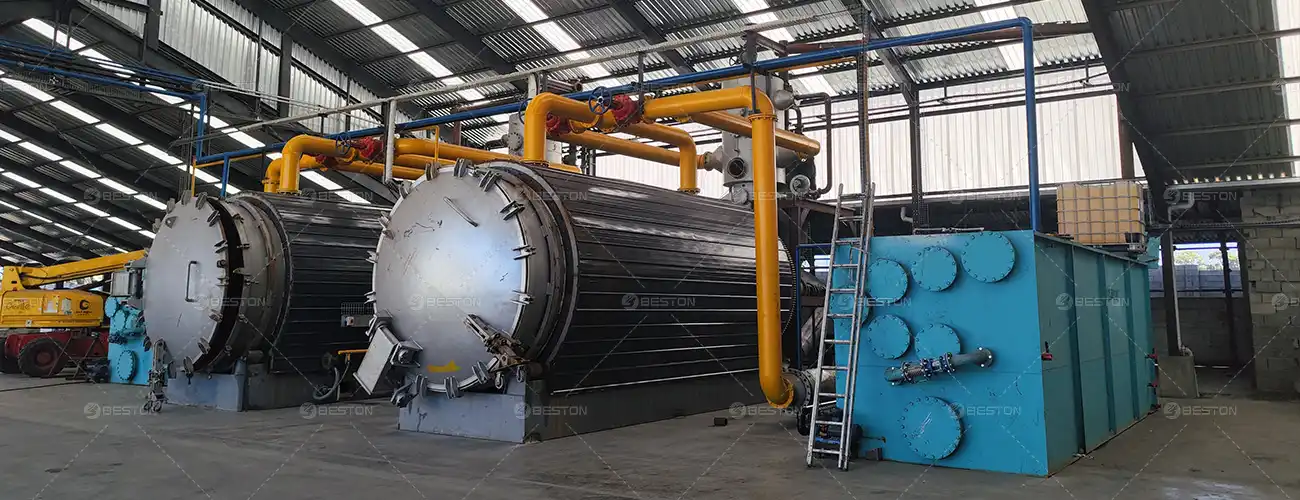

3. Action and Solution

Beston technical team comprehensively considered the feedstock type, processing capacity, production site, and customer needs. After a customized design, we provided the South African customer with a configuration consisting of two BLJ-16 rubber & plastic pyrolysis plant (equipped with catalytic towers) and BZJ-10 distillation unit. Features of this equipment configuration include:

- Large processing capacity: Each batch processes 8-10 tons of plastic. Furthermore, each batch processes 10-12 tons of rubber.

- Preventing wax oil clogging: The catalytic tower improves pyrolysis efficiency through catalysis. It reduces wax oil formation and maximizing pyrolysis oil output.

- Improving fuel quality: The distillation unit further purifies the pyrolysis oil to produce non-standard diesel. This ensures it meets higher fuel requirements.

4. Results Achieved

Beston Group assists the customer throughout the entire process, including equipment customization, manufacturing, delivery, and installation. Finally, upon project completion, the South African customer successfully converts waste plastic and rubber into fuel oil, significantly improving resource utilization. Specific achievements are as follows:

- Volume reduction: Up to 7,000 tons of plastic and rubber waste annually were effectively processed. It reduces waste accumulation and converts it into a valuable energy resource.

- Operating cost reduction: The customer successfully introduces fuel oil into the smelting plant as fuel for aluminum furnaces and as a fuel replacement for older trucks. It significantly reduces fuel costs.

- Environmental benefits: The reduced waste accumulation and the use of pyrolysis oil contribute to reduced fossil fuel consumption and lower carbon emissions.

Future Outlook

The successful implementation of the plastic/rubber pyrolysis project has brought significant economic and environmental benefits to South African customer. As market demand increases, the customer plans to further increase production capacity, thereby gradually maximizing production capacity. The South African customer hopes to inject greater energy substitution capabilities into future operations, helping it secure a place in the global energy transition.